Dec . 13, 2024 05:07 Back to list

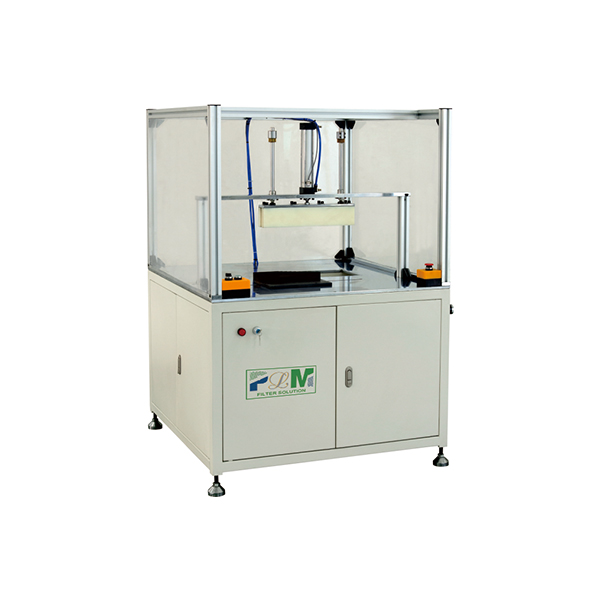

OEM PLCQ-1 Toyota Filter Element Pack Cutting Equipment for Efficient Production

Advancements in Automotive Manufacturing The OEM PLCQ-1 Toyota Filter Element Pack Cutting Machine

In the highly competitive automotive manufacturing industry, efficiency and precision remain paramount. As vehicle manufacturers strive for innovation, the introduction of advanced machinery plays a critical role in maintaining quality while optimizing production processes. One such development is the OEM PLCQ-1 Toyota filter element pack cutting machine, an advanced piece of equipment designed to enhance the production of filter elements for Toyota vehicles.

The PLCQ-1 machine serves as a cornerstone in the production of filter elements, which are essential components in a vehicle's engine for ensuring optimal performance and longevity. Filter elements are responsible for removing impurities and contaminants from oil, fuel, and air, thereby protecting the engine and other critical systems. Given its importance, the manufacturing process of these components must meet stringent quality standards, which the PLCQ-1 is designed to uphold.

Precision Cutting Technology

At the core of the OEM PLCQ-1 is its state-of-the-art cutting technology. This machine utilizes laser cutting and advanced blade systems, allowing for precision cuts that minimize waste while ensuring high-quality dimensions for each filter element pack. The incorporation of computer numerical control (CNC) technology means that adjustments to cutting specifications can be made quickly and efficiently, catering to various design requirements while streamlining the overall production process.

Furthermore, the PLCQ-1 is equipped with sensors and software that monitor the cutting process in real time. This feedback loop enables immediate corrections if any irregularities occur, thus reducing the risk of defective products reaching the market. The machine’s ability to maintain consistent quality underlines the commitment of Toyota and its manufacturing partners to delivering excellence.

Enhanced Production Efficiency

The OEM PLCQ-1 also emphasizes productivity. The machine boasts a high throughput rate, capable of producing a significant number of filter element packs in a short timeframe. Efficiency in production not only reduces lead times but also supports the automotive sector's demand for just-in-time manufacturing—an approach that minimizes inventory costs and enhances supply chain management.

oem plcq-1 toyota filter element pack cutting machine

In addition to its cutting capability, the PLCQ-1 features automation technologies that allow for seamless integration within the manufacturing line. Automated loading and unloading systems reduce manual handling, thereby decreasing labor costs and lessening the potential for human error. This combination of automated processes and high-speed cutting makes the PLCQ-1 an invaluable asset in modern automotive manufacturing.

Sustainability and Environmental Considerations

As the automotive industry increasingly prioritizes sustainability, the OEM PLCQ-1 aligns with these goals through its energy-efficient design. The machine utilizes eco-friendly technologies that reduce energy consumption during operation. Additionally, the precision of the cutting process leads to significantly less raw material waste, which is crucial in an era where environmental concerns drive manufacturing decisions.

Manufacturers are also placing emphasis on the recyclability of materials used in filter element production. The PLCQ-1 allows for easy handling of recyclable materials, contributing to a circular economy where waste is minimized and resources are reused.

Conclusion

The OEM PLCQ-1 Toyota filter element pack cutting machine represents a significant advancement in automotive manufacturing technology. By combining precision cutting, enhanced production efficiency, and a commitment to sustainability, the PLQC-1 not only meets the rigorous demands of modern automotive manufacturing but also sets a benchmark for the future of the industry.

As the automotive sector continues to evolve, adopting innovative technologies like the PLCQ-1 will be crucial for manufacturers aiming to retain a competitive edge. The integration of such advanced machinery exemplifies the industry's commitment to quality, efficiency, and environmental stewardship—elements that will undeniably shape the future of automotive production. Through investments in technologies like the PLCQ-1, manufacturers are not just enhancing their operations but are also paving the way for a more sustainable and prosperous automotive landscape.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025