डिस . 07, 2024 07:11 Back to list

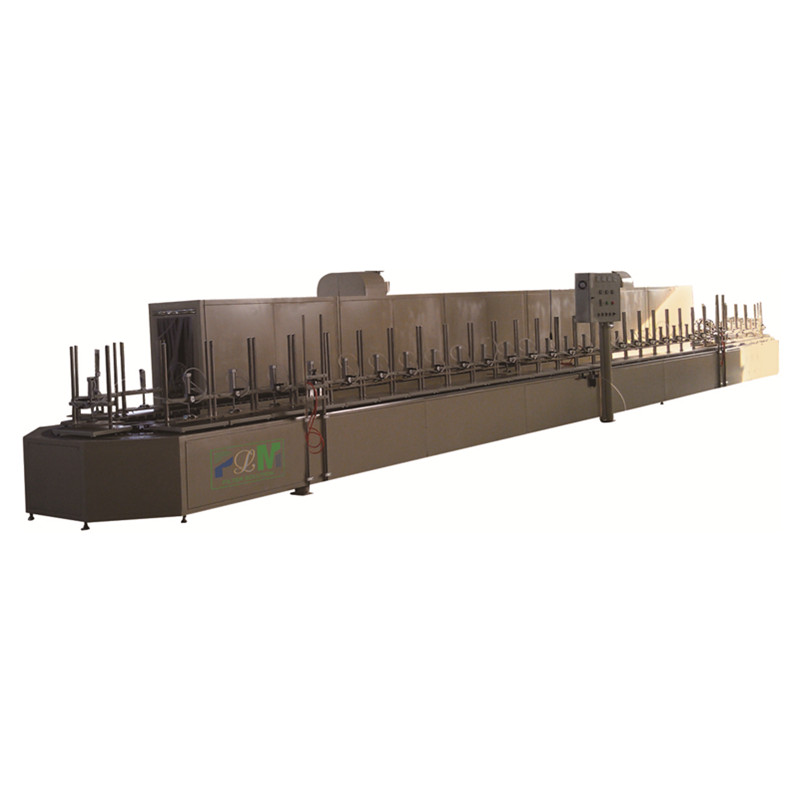

Exporters of Screw Press Sludge Dewatering Machines for Efficient Waste Management Solutions

The Role of Screw Press Sludge Dewatering Machines in Wastewater Treatment

In recent years, the issue of wastewater management has gained significant attention due to the increasing demand for clean water and the need to protect the environment. Among the various technologies employed for efficient sludge dewatering, screw press sludge dewatering machines have emerged as a highly effective solution. This article explores the functionality, benefits, and the growing market for these machines, particularly focusing on the role of exporters in the global trade.

Understanding Screw Press Sludge Dewatering Machines

Screw press sludge dewatering machines operate on a simple yet effective mechanism. They employ a screw conveyor to transport and compress the sludge, gradually separating the liquid from the solid content. This process results in a more manageable volume of sludge, significantly reducing disposal costs and improving handling efficiency. The technology is celebrated for its low energy consumption, ease of operation, and maintenance-friendly design.

One of the key advantages of screw press systems is their ability to handle a wide range of sludge types, including municipal wastewater sludge, industrial sludge, and specific sludges from food production processes. This versatility makes them suitable for a variety of applications, ranging from wastewater treatment plants to agricultural operations that require effective nutrient management.

Benefits of Screw Press Technology

1. High Dewatering Efficiency Screw press machines are known for their superior dewatering capabilities. They can achieve high solid contents in the discharged cake, which is essential for reducing transportation and disposal costs.

2. Reduced Energy Consumption The energy efficiency of screw presses is significantly better than that of traditional centrifuges and belt filter presses. This reduction in energy consumption not only lowers operational costs but also aligns with global sustainability initiatives.

3. Low Maintenance Requirements The design of screw press machines minimizes wear and tear, leading to lower maintenance costs. This aspect is particularly appealing for operators who need reliable and durable equipment for continuous operation.

4. Minimized Chemical Usage Unlike some other dewatering technologies that require chemicals for flocculation, screw presses rely primarily on mechanical processes. This feature can result in lower operational costs and reduced environmental impact.

screw press sludge dewatering machine exporters

5. Eco-friendly Solution By effectively reducing the volume of sludge, screw press dewatering machines contribute to lower landfill usage and decreased greenhouse gas emissions associated with waste disposal.

The Market Dynamics and Export Opportunities

As awareness about clean water and waste management grows, the demand for screw press sludge dewatering machines is steadily increasing on a global scale. Exporters play a crucial role in this market, as they facilitate the transfer of technology and equipment to various countries, particularly those in developing regions.

The international trade of sludge dewatering machines is influenced by several factors

- Rising Environmental Regulations Many countries are implementing stricter environmental regulations, prompting municipalities and industries to invest in advanced wastewater treatment technologies.

- Infrastructure Development As urbanization increases, there is a growing need for improved wastewater treatment infrastructure, which drives demand for efficient dewatering solutions.

- Technological Advancements Continuous improvements in screw press technology are making these machines more attractive to potential buyers. Exporters who stay at the forefront of innovation are well-positioned to capture market share.

- Cost Competitiveness Price-sensitive markets often favor cost-effective solutions. Exporters that can offer high-quality machines at competitive prices stand a better chance of succeeding in diverse markets.

Conclusion

Screw press sludge dewatering machines are transforming the wastewater treatment landscape, offering efficient, eco-friendly, and cost-effective solutions for sludge management. As the global market for these machines expands, exporters will play a pivotal role in meeting the growing demand, ensuring that advanced technology reaches those who need it most. By prioritizing efficiency and sustainability, the screw press technology not only addresses immediate wastewater challenges but also contributes to broader environmental goals. As we move forward, the investment in such technologies will undoubtedly shape the future of wastewater management and environmental protection.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025