Sep . 02, 2024 07:35 Back to list

304 Rimmed Filter Discs - High-Quality Filtration Solutions

The Importance of 304% Rimmed Filter Discs in Industrial Applications

In various industrial applications, filtration plays a crucial role in ensuring the purity and quality of products. One of the essential tools used in the filtration process is the 304% rimmed filter disc. This specialized tool is made from high-quality stainless steel, specifically grade 304, which is known for its excellent corrosion resistance and durability.

304 stainless steel is an alloy consisting of chromium and nickel, which enhances its ability to withstand harsh environments. This material is particularly beneficial in industries such as food and beverage, pharmaceuticals, and wastewater treatment, where the integrity of the filtration system is critical. The rimmed design of the filter disc not only aids in its stability but also facilitates effective filtration, allowing for better separation of solids from liquids.

The Importance of 304% Rimmed Filter Discs in Industrial Applications

Another advantage is the ease of cleaning and maintenance of 304% rimmed filter discs. Given that these filter discs are made from stainless steel, they can be easily cleaned, making them reusable in multiple filtration processes. This not only contributes to cost savings but also aligns with sustainable practices by minimizing waste. Industries concerned with environmental impact can benefit greatly from using durable and easily maintainable filtration tools.

304 rimmed filter disc

In terms of versatility, 304% rimmed filter discs can be adapted to various filtration processes. They can be used in coarse and fine filtration, depending on the requirements of the application. Whether it's the filtration of beverages to remove particulates or the separation of sludge in wastewater treatment, these filter discs are designed to meet a range of operational needs. Additionally, manufacturers can produce these discs in various sizes and mesh specifications, providing further customization for specific applications.

Moreover, the use of these filter discs can significantly enhance the overall efficiency of industrial processes. By ensuring that only the desired particles pass through, they can improve the quality of the final product. For instance, in the beverage industry, using a 304% rimmed filter disc may lead to clearer and cleaner beverages, which can enhance customer satisfaction and brand reputation.

Finally, as industries continue to evolve and integrate more technology and automation, the demand for reliable filtration solutions like the 304% rimmed filter disc is expected to grow. Businesses seek innovative and efficient ways to enhance their production processes, and high-quality filtration plays a pivotal role in achieving these objectives.

In conclusion, the 304% rimmed filter disc is an indispensable tool in modern industrial filtration applications. Its unique features, including corrosion resistance, high-pressure handling, ease of cleaning, and versatility, make it a preferred choice across multiple sectors. As industries strive for higher efficiency and sustainability, the relevance and demand for these filtration solutions will undoubtedly rise, underscoring their importance in ensuring product quality and operational success.

-

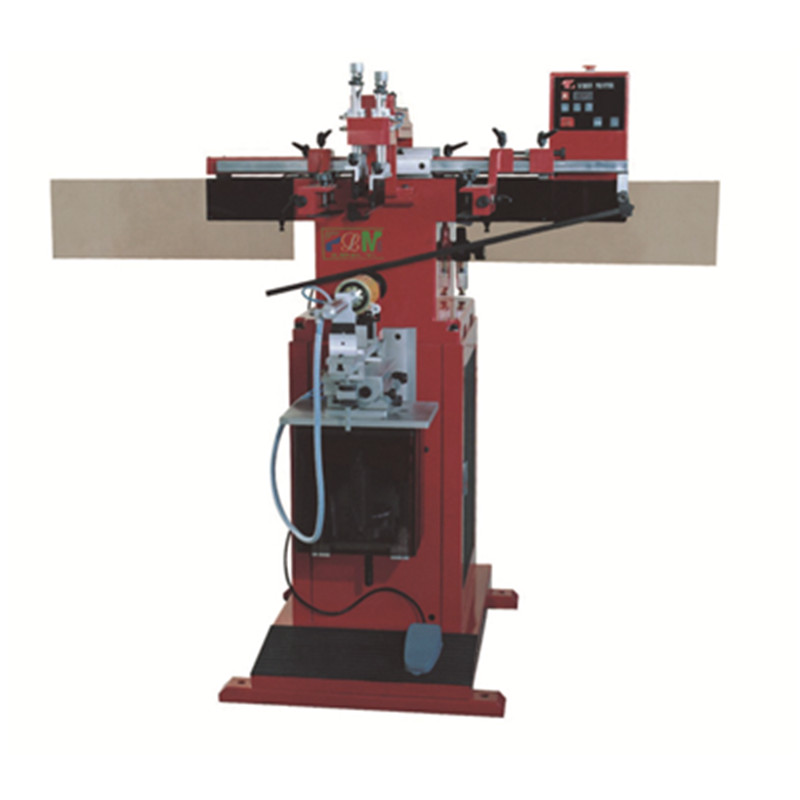

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.16,2025

-

PLAB-6 A/B Two-Component Filter Gluing Machine - Hebei Filter Man | Precision, Efficiency

NewsAug.16,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Adjustable Speed, Step Motor, Heat Mixing

NewsAug.16,2025

-

Eco-Friendly Coffee Filter Paper: Pure Taste, Sustainable Choice

NewsAug.16,2025

-

PLAB-6 Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025