Oct . 17, 2025 08:40 Back to list

Active Carbon Air Filter for Air Purifier – Odor Control

A Practical Insider’s Guide to the Active Carbon Layer in Modern Air Purifiers

If your living room still smells like last night’s stir‑fry (or the neighbor’s paint job), you’re already in the right conversation: the active carbon air filter for air purifier. To be honest, this is where a lot of the real magic happens—VOCs, odors, and pesky aldehydes meet a porous carbon maze and quietly disappear. Or mostly disappear, because real‑world loads vary.

What’s trending (and why it matters)

Industry-wide, we’re seeing multi-stage stacks: prefilter + HEPA/ePM1 + active carbon air filter for air purifier. The carbon stage is evolving fast—more coconut‑shell sources (lower ash), honeycomb blocks for lower pressure drop, and even chemically impregnated media for acid gases. Surprisingly, smaller form factors now squeeze in more adsorbent mass by using pleated pockets and better outer screens, which brings me to a neat piece of kit used upstream in production.

From raw carbon to a finished filter: the short version

Materials: coconut‑shell or bituminous activated carbon (pellets or granules), nonwoven carriers, adhesive/resin, and a metal or plastic outer screen. Methods range from stitched sachets to honeycomb modules and pleated carbon-loaded media. After filling and sealing, outer screens need forming, hooking, and flattening for rigidity and tidy edges.

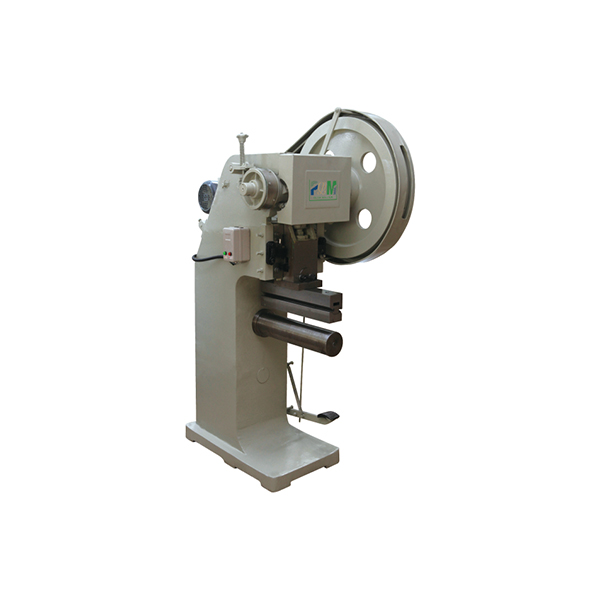

On the shop floor, equipment like the PLGY-500 Large Air Filter Outer Screen Hook Edge And Flattening Machine helps deliver that uniform shell—edge hooks, seam integrity, and consistent flatness—so the active carbon air filter for air purifier sits perfectly without whistling gaps. Origin: East of Anping County, Hengshui City, Hebei Province, China 053600. Description note says: “PLGY-500 Large Air Filter Outer Screen Hook Edge And Flattening Machine 18.” It’s a mouthful, but the output looks clean.

Representative specifications (typical build)

| Parameter | Typical value | Notes |

|---|---|---|

| Size (WxHxD) | 240×300×30 mm (custom) | Other footprints available |

| Carbon type | Coconut-shell pellets, 4×8 mesh | Impregnation optional for acid gases |

| Iodine number | ≈ 1000 mg/g | Adsorption capacity indicator |

| CTC adsorption | ≈ 60% | Real-world use may vary |

| Pressure drop @0.3 m/s | ≈ 60–90 Pa | Depends on media thickness and fill weight |

| TVOC removal (toluene) | Up to 90% initial | ISO 10121-2 bench test basis |

| Service life | 6–12 months | Load, RH, and VOC profile dependent |

Testing, standards, and real feedback

For gas‑phase media, ISO 10121-1/2 guides lab setups. Purifier-level performance often references GB/T 18801 (China) and, for particulate CADR, AHAM AC-1; ISO 16890 covers particle efficiency of the companion filter layer. In one controlled chamber I saw, a mid-size unit with a active carbon air filter for air purifier cut formaldehyde from ~0.20 mg/m³ to ~0.06 mg/m³ within 60 minutes (Annex F style test, around 30 m³, 0.3 m/s face velocity). Not a miracle cure, but noticeable. Many customers say the overnight “new furniture” smell is tamed in a day or two.

Where it fits best

- Homes with new paint, carpets, or pressed-wood furniture

- Small offices and design studios (solvent, marker odors)

- Clinics, hotel rooms, museums (light VOC and odor control)

- Smoking lounges (paired with HEPA and proper ventilation)

Vendor snapshot (equipment and filters)

| Vendor | Type | Strengths | Lead time | Customization | Certs |

|---|---|---|---|---|---|

| MFilterSolution (PLGY-500) | Equipment OEM | Outer screen hook-edge & flattening; stable seams | ≈ 20–35 days | Yes (dimensions, tooling) | ISO 9001 (typical for machinery) |

| Filter OEM A (Asia) | Filter manufacturer | Low MOQ, broad carbon options | ≈ 15–25 days | Yes (sizes, impregnation) | ISO 9001, RoHS |

| Brand B (EU) | Premium brand | Strong documentation, tight tolerances | ≈ 30–45 days | Limited | ISO 9001/14001; product safety files |

Customization tips

Ask for VOC profile matching (toluene vs. formaldehyde vs. sulfur compounds), RH range, target pressure drop, and minimum carbon mass. For kitchens, go heavier. For bedrooms, prioritize lower resistance and noise. I guess your nose will tell you if you got it right within a week.

Quick case notes

A design studio swapped in a thicker active carbon air filter for air purifier and reported “marker smell down by lunchtime.” A hotel client rotated filters quarterly; complaints fell, and HVAC energy stayed stable due to controlled pressure drop—outer screens formed on PLGY-500 kept frames true.

References

- ISO 10121-1/2: Gas-phase air cleaning media and devices — Test methods.

- ISO 16890 series: Air filters for general ventilation — Particle efficiency classification.

- GB/T 18801-2015 (and updates): Air cleaner — Performance and test methods (incl. formaldehyde).

- AHAM AC-1: Method for measuring the performance of portable room air cleaners.

- US EPA: Residential Air Cleaners — A Technical Summary (latest revision).

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025