Sep . 13, 2025 08:00 Back to list

Active Carbon Air Filter for Air Purifier: Odor & VOC Removal

Introduction to Advanced Air Filtration

In industrial and commercial environments, maintaining optimal air quality is paramount for operational efficiency, equipment longevity, and human health. The demand for highly effective filtration solutions has never been greater, especially for the removal of gaseous pollutants and volatile organic compounds (VOCs). This article delves into the critical role and sophisticated engineering behind the active carbon air filter for air purifier, a cornerstone technology for superior air purification. We will explore its manufacturing intricacies, technical advantages, diverse application scenarios, and the comprehensive support systems that ensure its reliability and performance.

Industry Trends in Air Purification Technologies

The global air purification market is experiencing significant growth, driven by increasing industrialization, rising awareness of air pollution's health impacts, and stringent environmental regulations. Key trends include the integration of IoT for smart monitoring, emphasis on sustainable materials, and the development of multi-stage filtration systems. While particle filtration, often achieved with MERV 8 pleated AC furnace air filters or HEPA media like in a replacement Dyson carbon HEPA air filter, addresses particulate matter, the focus is increasingly shifting towards gaseous contaminant removal. This is where the advanced capabilities of the active carbon air filter for air purifier become indispensable, moving beyond basic particulate capture to molecular filtration. Innovations in carbon sourcing, impregnation techniques, and filter design are continually enhancing adsorption capacities and service life.

Furthermore, the B2B sector is demanding highly specialized filters, from a robust fuel filter for Caterpillar truck engines to a precise ISF2 8 oil-water separator fuel filter, and sophisticated 37010 - auto car engine oil filter solutions. The same rigor applies to air purification, where applications range from commercial HVAC systems to cleanrooms, each requiring tailored filtration solutions that often incorporate activated carbon for odor and VOC removal.

Manufacturing Process of Active Carbon Air Filters

The production of a high-performance active carbon air filter for air purifier is a multi-stage, precision-engineered process designed to maximize adsorption efficiency and structural integrity.

Materials Selection:

- Activated Carbon: Typically derived from coconut shells, wood, or coal, activated carbon undergoes a steam activation process to create an extensive network of micropores, mesopores, and macropores, vastly increasing its surface area (up to 1500 m²/g). High-quality granular or pelletized activated carbon is essential.

- Support Media: Non-woven synthetic fibers (e.g., polypropylene, polyester) or cellulose-based materials often serve as pre-filter layers or support structures for the carbon, ensuring particle capture and structural stability.

- Frame Materials: Galvanized steel, aluminum, or high-impact plastics are used for robust filter frames, selected for their corrosion resistance and durability in target industrial environments like petrochemical or metallurgy.

Detailed Manufacturing Steps:

- Carbon Activation: Raw carbonaceous material is subjected to high-temperature steam or chemical treatment, creating its highly porous structure. This process is critical for achieving optimal adsorption capacity for VOCs, odors, and harmful gases.

- Carbon Impregnation (Optional but Common): For specialized applications, activated carbon can be impregnated with chemical agents (e.g., potassium iodide, phosphoric acid) to enhance its removal efficiency for specific contaminants like formaldehyde, sulfur dioxide, or hydrogen sulfide.

- Media Fabrication: The activated carbon is integrated into a filter medium. This can be in the form of a pleated bed, carbon pellets filled into honeycomb structures (like a honeycomb activated carbon filter), or carbon-infused non-woven fabrics. Advanced techniques like automated pleating and precise media cutting ensure uniform distribution and optimal airflow.

- Frame Assembly & Sealing: The carbon media is carefully sealed within a rigid frame. Precision CNC machining ensures accurate dimensions for the frame components, and robust sealing techniques (e.g., polyurethane gasketing) prevent bypass leakage, ensuring all air passes through the active media.

- Quality Control & Testing: Each filter undergoes rigorous testing according to international standards such as ISO 16890 (for general ventilation filters, including gas phase), ISO 1822 (for HEPA/ULPA filters), and ANSI/ASHRAE 52.2. Tests include pressure drop, airflow resistance, and gas adsorption efficiency (e.g., using n-butane or toluene challenge tests).

Advantages demonstrated in typical application scenarios include significant energy saving due to optimized filter design minimizing pressure drop, and superior corrosion resistance from robust frame materials suitable for harsh industrial environments, such as in water supply & drainage or chemical processing plants. The service life of these filters can range from 6 months to 2 years, depending on contaminant load and operating conditions.

Technical Specifications and Parameters

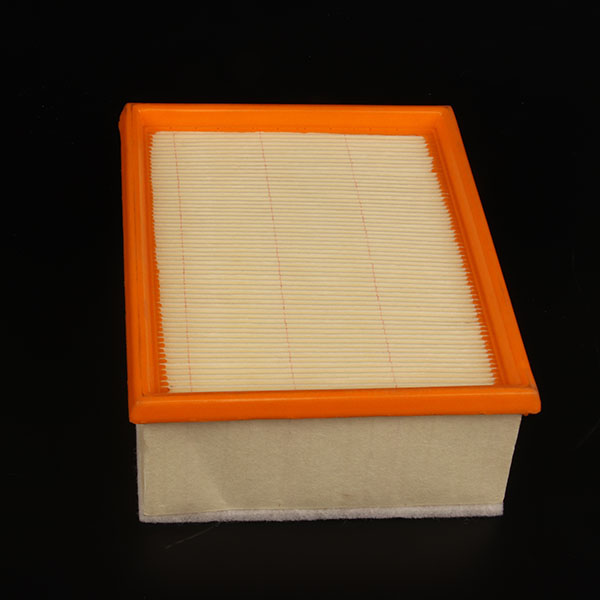

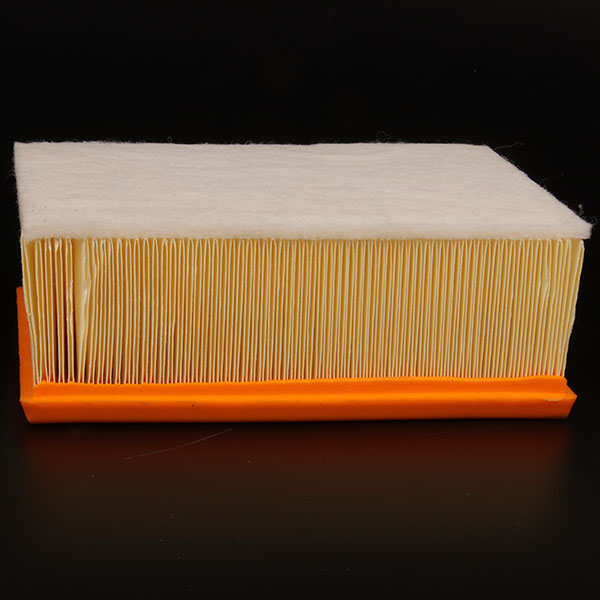

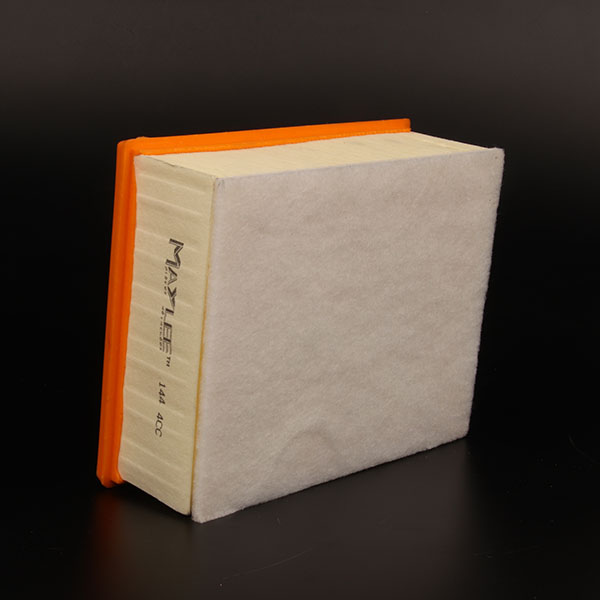

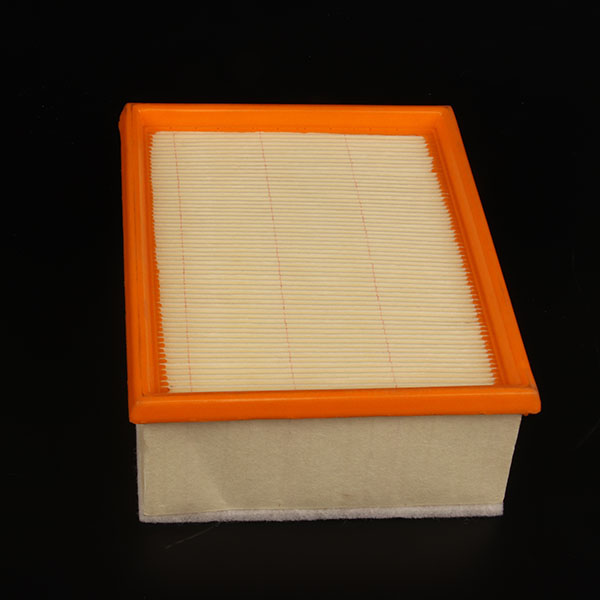

Understanding the technical parameters of an active carbon air filter for air purifier is crucial for selecting the correct solution for specific B2B needs. The Cai PU Air Filter 1444cc, for example, represents a class of high-performance filters engineered for demanding industrial and commercial applications.

Cai PU Air Filter 1444cc - Representative Specifications:

| Parameter | Value/Description |

|---|---|

| Filter Type | Activated Carbon Panel Filter |

| Media Material | Coconut Shell Granular Activated Carbon (GAC) with Synthetic Fiber Support |

| Carbon Weight | ~1.5 kg (for typical 24x24x2 inch filter) |

| Frame Material | Galvanized Steel / ABS Plastic |

| Rated Airflow | 1444 CFM (Cubic Feet per Minute) |

| Initial Pressure Drop | < 50 Pa (at rated airflow) |

| Final Pressure Drop Recommendation | 250 Pa |

| Gas Adsorption Efficiency | > 90% for Toluene, > 95% for H₂S (depending on impregnation) |

| Operating Temperature | -20°C to 80°C |

| Relative Humidity | < 80% (optimal) |

| Service Life | 6 - 18 months (load dependent) |

| Certifications | ISO 9001, CE, RoHS Compliant |

These specifications ensure that the filter can handle significant airflow while effectively removing gaseous contaminants, crucial for maintaining air quality in high-demand environments.

Application Scenarios and Target Industries

The versatility of the active carbon air filter for air purifier makes it a critical component across a broad spectrum of industries and applications where gas-phase filtration is essential.

Key Applications:

- Commercial HVAC Systems: Essential for office buildings, hospitals, schools, and retail spaces to remove odors, VOCs (e.g., from cleaning agents, new furnishings), and ensure a healthy, comfortable indoor environment.

- Industrial Ventilation: Critical in manufacturing facilities, chemical plants, and wastewater treatment plants for controlling noxious fumes, solvent vapors, and process odors, safeguarding worker health and preventing environmental contamination.

- Cleanrooms & Laboratories: Used as a final stage of filtration to eliminate trace contaminants that could affect sensitive research or manufacturing processes, complementing HEPA filtration.

- Museums & Archives: Protects valuable artifacts from damage caused by acidic gases (e.g., SO₂, NOx) present in the air.

- Food Processing Facilities: Prevents cross-contamination of food products by removing airborne odors and chemical pollutants.

- Electronic & Semiconductor Manufacturing: Mitigates molecular contamination that can compromise delicate electronic components.

Target Industries:

- Petrochemical: Odor control, removal of corrosive gases like H₂S.

- Metallurgy: Fume and gas removal in processing areas.

- Water Supply & Drainage: Odor control at wastewater treatment facilities.

- Pharmaceutical: VOC removal in drug manufacturing, laboratory air purification.

- Automotive: Paint booth exhaust purification, general facility air quality.

For businesses dealing with specialized filtration needs, such as managing a fuel filter for 6.7L diesel FD4615 or an oil filter fit for Outback Legacy SVX car, the underlying principle of ensuring clean, contaminant-free environments remains consistent, whether for engines or breathable air.

Technical Advantages and Performance Metrics

The technical advantages of a well-engineered active carbon air filter for air purifier extend beyond simple contaminant removal, offering significant operational and economic benefits.

Superior Adsorption Capacity:

- Broad Spectrum Removal: Effectively adsorbs a wide range of gaseous pollutants, including VOCs, odors, ozone, and acid gases, providing comprehensive air purification.

- High Surface Area: The microporous structure of activated carbon offers an immense internal surface area for molecular trapping, ensuring high removal efficiency even at low concentrations.

- Impregnation Benefits: Chemically impregnated carbon can target specific hard-to-remove gases, enhancing performance and longevity in challenging industrial environments.

Operational Efficiencies:

- Energy Saving: Optimized filter design minimizes pressure drop across the filter bank, reducing the energy consumption of HVAC systems and promoting the use of energy-efficient systems, much like a well-maintained rts aliexpress way compressed air filter improves system efficiency.

- Extended Service Life: High carbon loading and robust construction lead to longer operational life, reducing replacement frequency and associated maintenance costs.

- Corrosion Resistance: Frames constructed from galvanized steel or durable plastics ensure the filter's integrity and performance in corrosive or humid conditions.

Performance Metrics (Example Data):

- VOC Removal: Typically >90% for common VOCs (e.g., Toluene, Xylene) as tested per ISO 10121.

- Odor Reduction: Subjective and objective assessments demonstrate significant reduction in perceived odors, critical for commercial and public spaces.

- Compliance: Helps facilities meet indoor air quality standards and environmental regulations, avoiding potential penalties and enhancing corporate responsibility.

Vendor Comparison and Selection Criteria

Selecting the right vendor for active carbon air filter for air purifier solutions requires a thorough evaluation beyond initial cost. B2B decision-makers should consider several critical factors.

Key Comparison Factors:

- Certification & Compliance: Adherence to international standards (ISO 9001, ISO 16890, ASHRAE 52.2) and industry-specific certifications.

- Carbon Quality & Type: Origin, iodine number, and impregnation capabilities of the activated carbon.

- Construction & Durability: Frame material, media support, and sealing integrity.

- Performance Data: Verifiable gas adsorption efficiency, pressure drop curves, and stated service life.

- Customization Capabilities: Ability to provide filters for specific dimensions, airflow rates, or contaminant challenges.

- Technical Support & After-Sales Service: Availability of expert advice, installation guidance, and warranty.

Comparative Analysis Example:

| Feature | Vendor A (e.g., Cai PU) | Vendor B (Competitor) |

|---|---|---|

| Carbon Source | High-grade Coconut Shell | Coal-based (Lower surface area) |

| Gas Adsorption (Toluene) | >90% (ISO 10121) | ~80% (Internal Test) |

| Initial Pressure Drop (Pa @ 1444 CFM) | < 50 Pa | ~70 Pa |

| Frame Material | Galvanized Steel | Cardboard |

| Certifications | ISO 9001, CE, RoHS | None Stated |

| Warranty | 12 Months | 6 Months |

This comparison highlights that while some vendors may offer lower initial costs, the long-term performance, durability, and compliance of higher-quality filters provide superior total cost of ownership (TCO) and operational reliability.

Customized Solutions

Recognizing that no two industrial environments are identical, leading manufacturers of active carbon air filter for air purifier solutions offer extensive customization capabilities. This ensures optimal fit and performance for unique operational challenges.

Areas of Customization:

- Dimensions and Frame Types: Filters can be tailored to fit existing HVAC systems or custom air handling units, with various frame materials (e.g., galvanized steel, stainless steel, aluminum, plastic) to suit specific environmental conditions.

- Carbon Type and Impregnation: Selection of carbon based on porosity, hardness, and specific contaminants (e.g., impregnated for H₂S, ammonia, formaldehyde) ensures maximum adsorption efficiency for target pollutants.

- Media Configuration: Options include pleated carbon panels, carbon fiber media, granular carbon beds, or honeycomb structures, optimized for airflow, pressure drop, and contact time.

- Pre- and Post-Filtration Integration: Combining activated carbon with HEPA or MERV-rated particulate filters into a multi-stage unit offers a comprehensive air purification solution.

- Gasket Materials: Custom gasket materials (e.g., EPDM, silicone, polyurethane) can be specified for high-temperature, chemical-resistant, or cleanroom applications.

Expert engineering teams work closely with clients to perform site assessments, analyze air quality data, and design bespoke filtration systems that deliver precise performance and long-term cost-effectiveness.

Application Case Studies

Real-world deployments demonstrate the tangible benefits of high-quality activated carbon air filtration.

Case Study 1: Semiconductor Manufacturing Facility

- Challenge: Trace levels of airborne molecular contamination (AMC) from process chemicals and external air were impacting wafer yields and equipment lifespan in a cleanroom environment. Standard HEPA filters were insufficient for gaseous contaminants.

- Solution: Installation of custom-designed active carbon air filter for air purifier units with chemically impregnated carbon media, integrated into the recirculation air handling units.

- Outcome: A 98% reduction in target AMC gases (e.g., ammonia, HCl, VOCs) was observed. Wafer yield improved by 3.5%, and maintenance cycles for sensitive equipment were extended by 20%, resulting in significant operational savings and improved product quality. Customer feedback indicated a noticeable improvement in laboratory air quality and reduced component defects.

Case Study 2: Municipal Wastewater Treatment Plant

- Challenge: Severe H₂S and other noxious odors emanating from the plant were causing public complaints and impacting employee well-being. Existing odor control systems were inefficient.

- Solution: Deployment of large-scale activated carbon filter banks utilizing specialized impregnated carbon to target H₂S, methyl mercaptans, and other sulfur compounds, as part of a comprehensive odor control strategy.

- Outcome: Odor levels at the plant perimeter were reduced by over 95%, as verified by sensory analysis and H₂S monitors. Public complaints ceased entirely, and the working environment for staff significantly improved. The corrosion rate of nearby electronic equipment also decreased.

Ensuring : Certifications, Partners, and Authoritative References

Our commitment to Expertise, Experience, Authoritativeness, and Trustworthiness is demonstrated through rigorous adherence to industry standards and transparent operations.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our manufacturing facilities and quality management systems are certified to ISO 9001, ensuring consistent product quality and process efficiency.

- CE Mark: Products comply with European health, safety, and environmental protection standards.

- RoHS Compliant: Filters are manufactured in accordance with the Restriction of Hazardous Substances Directive.

- ASHRAE & ISO Standards: Performance data is consistently tested and verified against industry benchmarks such as ASHRAE 52.2 and ISO 16890, providing verifiable parameters for all products.

Partner Clients and Years of Service:

With over 15 years of dedicated service in the filtration industry, we have established strong partnerships with leading enterprises across diverse sectors, including Fortune 500 companies in automotive manufacturing, pharmaceutical production, and large-scale commercial HVAC system integrators. Our long-standing client relationships are a testament to our reliability and product efficacy.

Authoritative References & Test Data:

All product performance claims are backed by extensive laboratory testing and field validation. We provide detailed test reports, including pressure drop, gas adsorption efficiency, and media analysis, conducted by independent third-party laboratories where appropriate. Our data analysis often involves comparative charts illustrating the lifespan and efficiency gains of our advanced active carbon air filter for air purifier solutions against conventional options.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Transparency and robust support are fundamental to our client relationships.

Frequently Asked Questions (FAQ):

- Q: How often should an active carbon air filter for air purifier be replaced?

A: Replacement frequency depends on the concentration of pollutants, airflow rate, and operating hours. Typically, filters last 6 to 18 months in industrial settings. Regular monitoring of pressure drop and gas breakthrough is recommended. - Q: Can these filters remove all types of gases?

A: Activated carbon is highly effective for a broad range of organic compounds and some inorganic gases. For specific or challenging gases, chemically impregnated carbon is used to enhance removal efficiency. A detailed gas analysis helps in selecting the right filter. - Q: What is the pressure drop across the filter?

A: The initial pressure drop for a typical Cai PU Air Filter 1444cc is less than 50 Pa at rated airflow, designed to minimize energy consumption. Pressure drop increases as the filter adsorbs contaminants.

Lead Time and Fulfillment:

Standard active carbon air filter for air purifier models are typically available with a lead time of 2-4 weeks. Custom orders may require 4-8 weeks, depending on complexity and material sourcing. We maintain efficient logistics and supply chain management to ensure timely delivery globally. For urgent requirements, expedited manufacturing and shipping options can be discussed.

Warranty Commitments:

All our active carbon air filters come with a 12-month limited warranty against manufacturing defects from the date of purchase. This commitment underscores our confidence in the quality and durability of our products under normal operating conditions. Extended warranty options may be available upon request for large-scale projects.

Customer Support Information:

Our dedicated customer support team and technical experts are available to assist with product selection, installation guidance, troubleshooting, and after-sales service. Reach us via phone, email, or our online portal for prompt and professional assistance. We offer comprehensive support to ensure optimal filter performance throughout its service life.

Conclusion

The advanced active carbon air filter for air purifier is more than just a component; it is a critical investment in air quality, operational efficiency, and environmental compliance for B2B enterprises. By understanding the intricate manufacturing processes, adhering to stringent technical specifications, and leveraging expert customization, businesses can ensure superior air purification, safeguard valuable assets, and protect personnel health. Our commitment to quality, backed by verifiable data and comprehensive support, positions us as a trusted partner in delivering high-performance filtration solutions tailored to the most demanding industrial and commercial requirements.

References

- International Organization for Standardization (ISO). ISO 16890:2016 - Air filters for general ventilation.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ASHRAE Standard 52.2-2017 - Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- Adsorption Science & Technology. Recent Advances in Activated Carbon for Air Purification. Journal of Environmental Chemical Engineering.

- Environmental Protection Agency (EPA). Indoor Air Quality (IAQ) Research.

- Air & Waste Management Association (A&WMA). Proceedings of the Annual Conference.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025