Sep . 22, 2025 13:25 Back to list

Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

Industry Trends in Air Purification Filtration

The global air purification market is experiencing significant growth, driven by increasing awareness of air quality impacts on health and stringent environmental regulations. Businesses across various sectors are investing in advanced filtration solutions to protect personnel, sensitive equipment, and maintain product integrity. A critical component in this ecosystem is the active carbon air filter for air purifier, which plays a pivotal role in removing volatile organic compounds (VOCs), odors, and gaseous pollutants.

Emerging trends point towards higher efficiency standards, such as those seen in HEPA filtration, often coupled with activated carbon for comprehensive purification. There's also a growing demand for customized solutions, moving beyond generic filters like the merv 8 pleated ac furnace air filter, to highly specialized systems. The integration of smart technologies for real-time monitoring of filter performance and replacement cycles is also gaining traction, enhancing operational efficiency and reducing downtime. Furthermore, the push for sustainability is leading to innovations in filter materials and manufacturing processes that are more environmentally friendly and offer extended service life.

The market is witnessing a shift from standard particulate filters to multi-stage filtration systems that address both solid particles and gaseous contaminants. This is particularly relevant in environments where chemical fumes, industrial odors, or biological aerosols are prevalent, necessitating the robust capabilities of active carbon air filter for air purifier technology. Companies are increasingly seeking filters that not only meet current standards but are also adaptable to future regulatory changes and evolving contaminant profiles.

Technical Specifications and Parameters

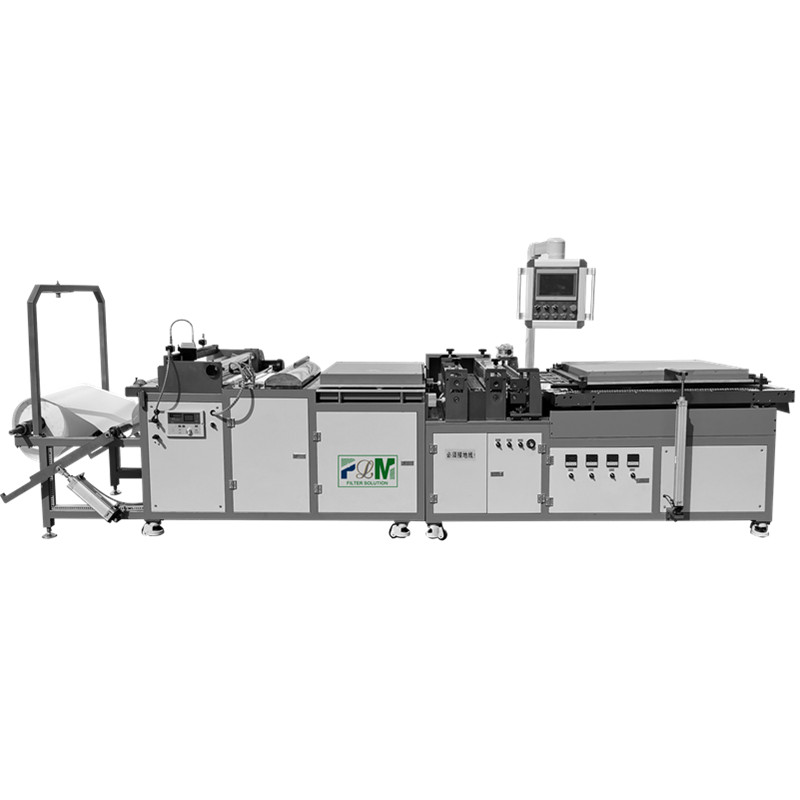

Understanding the technical specifications of filtration media is paramount for B2B buyers. The LM-ZZ-5 Drum type air filter origami (800 type), for instance, utilizes a high-surface-area activated carbon media, critical for its adsorption capabilities. Activated carbon's effectiveness is primarily determined by its porosity, pore size distribution, and surface chemistry.

Key parameters for assessing a high-performance active carbon air filter for air purifier include:

- Adsorption Capacity: Measured in grams of pollutant adsorbed per gram of carbon (g/g), indicating the filter's ability to remove specific gases like SO2, NOx, or VOCs.

- Airflow Resistance (Pressure Drop): The pressure difference across the filter, which directly impacts energy consumption of the air handling unit. Lower pressure drop is desirable for energy efficiency.

- Removal Efficiency: Percentage of target contaminants removed from the airstream. This often varies based on the type and concentration of the pollutant.

- Carbon Bed Depth: A deeper carbon bed generally offers longer contact time and higher removal efficiency, albeit with potentially higher initial pressure drop.

- Particle Size of Carbon: Smaller carbon particles can offer more surface area but may lead to higher pressure drop if not properly structured.

- Service Life: The operational duration before the filter reaches saturation and requires replacement, influenced by contaminant load and airflow.

LM-ZZ-5 Drum Type Air Filter Origami (800 Type) Specifications

| Parameter | Value / Description |

|---|---|

| Product Model | LM-ZZ-5 Drum type air filter origami (800 type) |

| Filter Media | High-grade Granular Activated Carbon (GAC) / Impregnated Carbon |

| Frame Material | Galvanized Steel / ABS Plastic (customizable) |

| Nominal Airflow (m³/h) | 800 - 1200 |

| Initial Pressure Drop (Pa) | < 100 Pa at nominal airflow |

| Adsorption Efficiency (Benzene) | ≥ 90% (initial) |

| Operating Temperature Range | -20°C to 80°C |

| Relative Humidity | ≤ 90% |

| Typical Service Life | 6-12 months (dependent on contaminant load) |

These specifications ensure that the LM-ZZ-5 provides reliable and efficient air purification, crucial for maintaining air quality in demanding industrial and commercial settings.

Manufacturing Process of Active Carbon Air Filters

The creation of a high-quality active carbon air filter for air purifier involves a precise multi-stage manufacturing process, ensuring optimal performance and longevity. This detailed process flow outlines the journey from raw material to finished product.

Process Flow Steps:

- Raw Material Sourcing and Activation:

- Materials: High-grade coconut shells, wood, or coal are typically used as precursors for activated carbon. For the LM-ZZ-5, we utilize a premium blend for optimal pore structure.

- Activation: The carbon precursor undergoes either physical (steam/CO2) or chemical activation (e.g., phosphoric acid). This process creates a highly porous structure, vastly increasing the surface area for adsorption.

- Carbon Granulation/Pelletization:

- Activated carbon is milled and sieved to achieve a specific particle size, or extruded into pellets. This ensures uniform density and airflow characteristics within the filter media.

- Media Formulation and Impregnation (Optional):

- For specialized applications, the activated carbon may be impregnated with chemicals (e.g., potassium iodide, potassium permanganate) to enhance its ability to chemisorb specific target gases like formaldehyde or hydrogen sulfide.

- The formulated carbon is then carefully integrated into the filter structure, which might be in a pleating, honeycomb, or granule-filled bed configuration, similar to a honeycomb activated carbon filter.

- Frame Manufacturing (CNC Machining/Injection Molding):

- Frames, often made from galvanized steel or high-grade ABS plastic, are manufactured using precise CNC machining or injection molding to ensure structural integrity and a perfect seal.

- For drum-type filters like the LM-ZZ-5, the cylindrical frame is designed for robust performance in demanding environments.

- Assembly and Sealing:

- The carbon media is carefully packed into the filter frame, ensuring uniform distribution to prevent bypass and maximize contact efficiency. Advanced origami techniques are employed for models like the LM-ZZ-5 to optimize media density and airflow.

- Gaskets and sealants are applied to create an airtight seal, preventing untreated air from bypassing the filter media.

- Quality Control and Testing Standards:

- Each filter undergoes rigorous testing according to international standards such as ISO 10121 (for gas phase air filters), ASHRAE 52.2, and EN 1822 (for HEPA/ULPA components, if combined).

- Tests include initial pressure drop, overall adsorption efficiency for various target gases, and structural integrity. Filters like the LM-ZZ-5 are also tested for their durability and corrosion resistance.

- Packaging and Dispatch:

- Filters are securely packaged to prevent damage during transit, ready for distribution to diverse target industries.

Target Industries and Advantages:

The LM-ZZ-5 and similar active carbon air filter for air purifier solutions find extensive use in:

- Petrochemical: Removing H2S, mercaptans, and other sulfur compounds to protect sensitive instrumentation and personnel.

- Metallurgy: Mitigating acid gases (e.g., SO2, NOx) and fumes from smelting processes.

- Water Treatment: Odor control in pumping stations and treatment facilities, akin to the need for a reliable `isf2 8 oil-water separator fuel filter` in engine systems that deal with contaminants.

- Pharmaceutical and Biotech: Ensuring ultra-clean air by removing airborne molecular contaminants (AMCs) that can affect product quality.

- Commercial HVAC and Data Centers: Protecting electronics from corrosive gases and enhancing occupant comfort.

Typical Application Scenario Advantages (e.g., Energy Saving, Corrosion Resistance): In a data center, the LM-ZZ-5's low initial pressure drop contributes to significant energy savings by reducing the load on HVAC fans. Its robust construction and chemical impregnation provide superior corrosion resistance, protecting expensive server equipment from gaseous contaminants like hydrogen sulfide and chlorine, which are notoriously damaging to electronics. This extends the service life of critical infrastructure and minimizes maintenance costs, demonstrating a clear ROI for our clients.

Application Scenarios and Technical Advantages

The versatility of the active carbon air filter for air purifier makes it indispensable in a broad spectrum of B2B applications, far beyond consumer-grade `replacement dyson carbon hepa air filter` units. Its technical advantages translate directly into operational benefits and cost savings for industrial and commercial clients.

Core Application Scenarios:

- Industrial Exhaust Air Treatment: Essential for removing noxious fumes, solvent vapors, and odors from manufacturing processes, ensuring compliance with air quality regulations.

- Commercial Building HVAC Systems: Enhancing indoor air quality (IAQ) by adsorbing VOCs from furnishings, cleaning products, and outdoor pollution, benefiting occupants' health and productivity.

- Museums and Archives: Protecting sensitive artifacts from degradation caused by airborne pollutants such as sulfur dioxide and nitrogen oxides.

- Laboratories and Cleanrooms: Critical for maintaining ultra-pure air by eliminating chemical contaminants that could interfere with experiments or production.

- Wastewater Treatment Plants: Effective odor control, specifically targeting hydrogen sulfide (H2S) and ammonia (NH3) emissions that can be a nuisance to surrounding communities.

Technical Advantages:

- Broad Spectrum Adsorption: Activated carbon effectively adsorbs a wide range of gaseous pollutants, including VOCs (e.g., formaldehyde, benzene), odors, and certain inorganic gases. This is a distinct advantage over filters designed solely for particulates, like basic `merv 8 pleated ac furnace air filter`.

- High Adsorption Capacity & Efficiency: Our filters utilize high-grade activated carbon with optimized pore structures, leading to extended service life and consistent removal efficiency, even under varying contaminant loads.

- Low Energy Consumption: Engineered for minimal pressure drop, the LM-ZZ-5 reduces the energy burden on HVAC systems, leading to significant operational cost savings over the filter's lifetime.

- Robust Construction: Designed for industrial longevity, the frame and media construction resist corrosion and maintain structural integrity in challenging environments, unlike the often disposable nature of some smaller filters such as a `37010 - auto car engine oil filter`.

- Modular Design & Easy Maintenance: The drum type design facilitates easier installation and replacement compared to cumbersome, multi-component systems, minimizing downtime for critical operations.

- Customizable Impregnation: For specific chemical threats, our carbon media can be impregnated to target and neutralize particular gases, offering a tailored solution where standard carbon might fall short.

These advantages underscore the value proposition for businesses seeking reliable and efficient air purification solutions that go beyond basic particle filtration.

Vendor Comparison and Competitive Edge

When selecting a provider for active carbon air filter for air purifier solutions, B2B clients must consider not only product specifications but also manufacturing prowess, customization capabilities, and after-sales support. While many suppliers exist, differentiation often lies in material science, engineering precision, and a commitment to customer-specific needs.

Competitive Landscape Analysis:

| Feature / Vendor | MFilterSolution (LM-ZZ-5) | Competitor A (Mid-tier) | Competitor B (Budget) |

|---|---|---|---|

| Activated Carbon Quality | Premium Coconut Shell / Impregnated | Standard Coal-based | Basic Wood-based |

| Adsorption Capacity (Benzene) | ≥ 90% | ≈ 80% | ≈ 65% |

| Initial Pressure Drop (Pa) | < 100 Pa | 120-150 Pa | > 180 Pa |

| Service Life (Typical) | 6-12 months | 4-8 months | 3-6 months |

| Frame Durability | Galvanized Steel / ABS (High-grade) | Galvanized Steel (Standard) | Cardboard / Light Plastic |

| Customization Options | Extensive (media, size, impregnation) | Limited (size variants) | Minimal (off-the-shelf) |

| Certifications | ISO 9001, CE, RoHS | ISO 9001 | Basic internal testing |

Our LM-ZZ-5 Drum type air filter origami (800 type) stands out by offering a superior balance of high performance, energy efficiency, and durability. Unlike generic suppliers, we prioritize the quality of activated carbon and precision in manufacturing, translating to better long-term value for our clients. While a `rts aliexpress way compressed air filter` might offer quick, low-cost solutions, the specialized demands of industrial air purification necessitate filters built to stringent standards.

Customized Solutions and Application Case Studies

Understanding that no two industrial environments are identical, we specialize in providing bespoke filtration solutions. Our approach ensures that each active carbon air filter for air purifier integrates seamlessly into existing infrastructure and precisely addresses specific contaminant challenges, unlike the standardized options for a `fuel filter for caterpillar truck engine` or `oil filter fit for outback legacy svx car`.

Customization Capabilities:

- Media Selection & Impregnation: We can select specific activated carbon types (e.g., coconut shell, coal-based) and apply targeted chemical impregnations to optimize removal for particular gases (e.g., acid gases, alkaline gases, mercury).

- Dimensions and Configuration: Filters can be tailored to fit unique housing dimensions or airflow requirements, including specific drum diameters, lengths, and pleat configurations.

- Frame Materials: Options for frame materials extend beyond standard galvanized steel to include stainless steel for highly corrosive environments or specialized plastics for lightweight applications.

- Multi-stage Integration: Our active carbon air filter for air purifier can be designed as part of multi-stage filtration units, integrating with particulate filters (HEPA/ULPA) to provide comprehensive air purification.

Application Case Studies:

Case Study 1: Semiconductor Manufacturing Facility

- Challenge: A leading semiconductor manufacturer required ultra-clean air to prevent yield losses due to airborne molecular contaminants (AMCs) like ammonia, VOCs, and sulfur compounds, which can etch microchips.

- Solution: We designed a custom LM-ZZ-5 drum filter system with specialized chemically impregnated activated carbon, specifically tailored to target sub-ppb levels of these AMCs. The filters were configured into a compact, modular design for easy integration into their existing cleanroom HVAC system.

- Results: Post-installation, AMC levels dropped significantly, leading to a measurable increase in production yield and a reduction in defective products by 15% within six months. The extended service life of our filters also reduced maintenance frequency by 30%.

Case Study 2: Municipal Wastewater Treatment Plant Odor Control

- Challenge: A wastewater treatment plant faced persistent community complaints about foul odors, primarily hydrogen sulfide (H2S), mercaptans, and ammonia, emanating from their facilities. Existing odor control methods were insufficient.

- Solution: We implemented a series of large-scale LM-ZZ-5 filters featuring a robust, corrosion-resistant galvanized steel frame and highly impregnated activated carbon media optimized for H2S and NH3 removal. The drum design allowed for high airflow rates with minimal pressure drop.

- Results: Within weeks, ambient odor concentrations around the plant dropped below detection limits. Community complaints ceased entirely, and the plant achieved compliance with local air quality standards. The durability of the filters ensured consistent performance in a high-humidity, corrosive environment. This contrasts sharply with the demands on a `fuel filter for 6.7l diesel fd4615` which, while critical, operates in a different, more isolated environment.

These case studies highlight our capability to deliver measurable improvements in air quality and operational efficiency through tailored active carbon air filter for air purifier solutions.

Frequently Asked Questions (FAQ)

- Q: How often should an active carbon air filter for an air purifier be replaced?

- A: The service life of an active carbon air filter for air purifier varies significantly based on the concentration and type of gaseous contaminants, airflow rates, and operating environment. Typically, for industrial applications, replacement is recommended every 6 to 12 months. Regular monitoring of pressure drop and occasional lab analysis of the spent carbon can help determine the optimal replacement schedule. Our LM-ZZ-5 models are designed for consistent performance over this typical range.

- Q: Can these filters remove all types of gaseous pollutants?

- A: While activated carbon is highly effective for a broad range of organic compounds (VOCs) and some inorganic gases, its effectiveness varies. For specific, challenging contaminants like ammonia, hydrogen sulfide, or certain acid gases, chemically impregnated activated carbon is often used to enhance removal efficiency through chemisorption. We offer specialized media types to target nearly any gaseous pollutant.

- Q: What is the lead time for large orders?

- A: For standard LM-ZZ-5 models, typical lead time is 4-6 weeks for quantities up to 500 units. Customized solutions or larger orders may require 8-12 weeks, depending on the complexity and material availability. We maintain strategic inventory levels for common components to facilitate prompt delivery. For comparison, managing supply chains for an `rts aliexpress way compressed air filter` typically differs significantly due to scale and customization needs.

- Q: What warranty is provided with your air filters?

- A: We offer a standard 12-month limited warranty on our active carbon air filter for air purifier products, covering defects in materials and workmanship under normal operating conditions. This warranty ensures product quality and provides peace of mind for our industrial clients. Specific terms and conditions are provided with each quotation.

- Q: How do you handle after-sales support and technical assistance?

- A: Our dedicated after-sales support team is available for technical consultations, installation guidance, and troubleshooting. We provide comprehensive documentation, and our engineers are available for on-site visits for complex system integrations or performance assessments. We are committed to ensuring our clients achieve optimal air purification performance throughout the product lifecycle.

Authoritative References

- ISO 10121-1:2014. "Test methods for assessing the performance of gas-phase air cleaning media and devices for general ventilation - Part 1: Gas-phase air cleaning media." International Organization for Standardization.

- ASHRAE Standard 52.2-2017. "Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size." American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Wang, S., & Zhu, Z. H. (2007). "Environmental applications of adsorption by activated carbon fibers." Environmental Science & Technology, 41(1), 32-38.

- Centers for Disease Control and Prevention (CDC). "Indoor Air Quality." National Institute for Occupational Safety and Health (NIOSH).

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025