Aug . 15, 2024 02:20 Back to list

Advanced Ultrasonic Welding Machine for High-Precision Industrial Applications and Enhanced Material Bonding Solutions

The PLCS-1 Ultrasonic Welding Machine Revolutionizing Manufacturing Processes

In the ever-evolving landscape of manufacturing technology, the PLCS-1 ultrasonic welding machine has emerged as a game-changer. Combining precision, efficiency, and versatility, this machine is designed to meet the diverse needs of industries ranging from automotive to electronics. Ultrasonic welding, which utilizes high-frequency sound waves to join materials, offers several advantages over traditional methods, making the PLCS-1 a valuable asset for businesses aiming to enhance their production capabilities.

The PLCS-1 Ultrasonic Welding Machine Revolutionizing Manufacturing Processes

The versatility of the PLCS-1 makes it suitable for various applications. It can weld thermoplastics, metals, and even certain textiles, allowing manufacturers to adopt it across multiple sectors. Whether it’s assembling automotive components, joining plastic housings for electronic devices, or creating durable connections in medical devices, the PLCS-1 provides a reliable solution tailored to different materials and thicknesses. This adaptability enhances its value, as businesses can leverage a single machine for multiple applications.

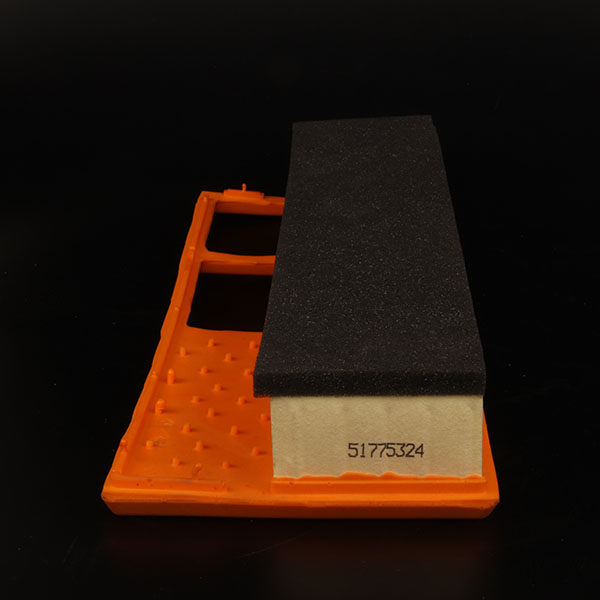

plcs-1 ultrasonic welding machine product

Moreover, the PLCS-1 ultrasonic welding machine boasts advanced control systems that enable precise adjustments to the welding parameters. This capability ensures consistent quality in every weld, reducing the likelihood of defects and rework. Manufacturers can fine-tune factors such as amplitude, pressure, and time, optimizing the welding process for specific materials and requirements. As a result, companies can achieve higher standards of quality assurance, which is crucial in industries where safety and reliability are paramount.

Energy efficiency is another notable feature of the PLCS-1. Ultrasonic welding consumes significantly less energy compared to traditional methods like thermal welding or adhesive bonding. This eco-friendly attribute not only contributes to lower operational costs but also aligns with the global push towards sustainable manufacturing practices. Companies adopting the PLCS-1 will find themselves better positioned to meet environmental regulations and appeal to increasingly conscious consumers.

Additionally, the PLCS-1 ultrasonic welding machine is designed with the operator in mind. Its user-friendly interface simplifies the setup process, allowing operators to quickly switch between tasks and materials. This ease of use minimizes training time and empowers workers to maximize the machine's potential, leading to operational efficiencies and a more engaged workforce.

In conclusion, the PLCS-1 ultrasonic welding machine represents a significant advancement in manufacturing technology. Its combination of speed, precision, adaptability, and energy efficiency makes it an indispensable tool for various industries. As companies continue to strive for greater efficiency and quality in their production processes, the PLCS-1 stands out as a reliable solution that not only meets current demands but also prepares businesses for future challenges. Investing in such innovative technology is not just a smart move but a necessary step toward maintaining competitiveness in a rapidly changing manufacturing landscape. With the PLCS-1, manufacturers can focus on what truly matters delivering high-quality products to their customers swiftly and efficiently.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025