Sep . 29, 2024 02:28 Back to list

Air Filter Production Equipment for Efficient Manufacturing Solutions

The Importance of Air Filter Machine Manufacturing

In an age where air quality is increasingly jeopardized by industrialization and urbanization, air filter machines have become essential in ensuring a cleaner and healthier environment. These machines play a critical role in various sectors, including automotive, electronics, and healthcare, where maintaining high air quality standards is paramount.

Air filter machine manufacturing involves a sophisticated process of designing and producing machines that can efficiently filter out pollutants, dust, allergens, and other harmful particulates from the air. The primary objective of these machines is to enhance indoor air quality (IAQ) and ensure that industrial emissions comply with environmental regulations.

Components of Air Filter Machines

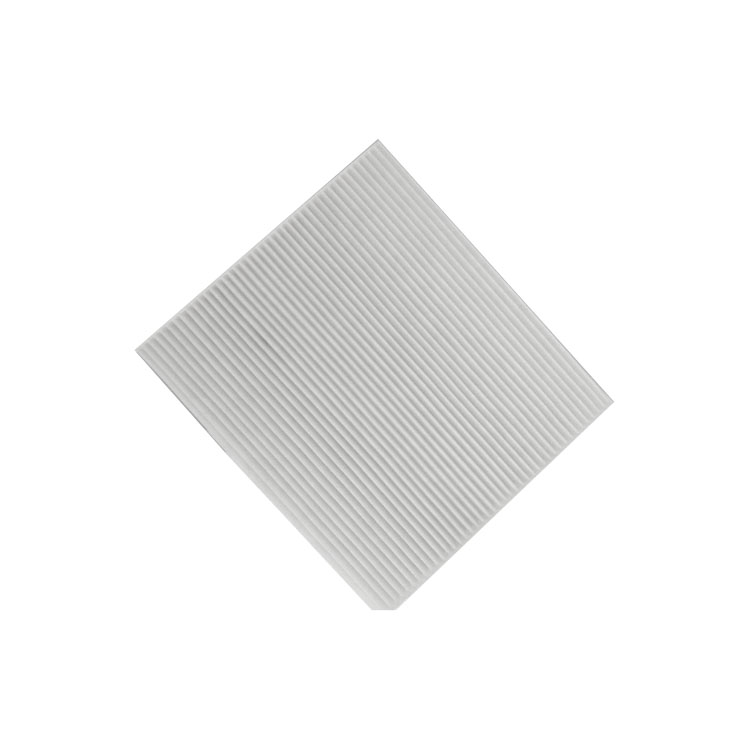

Air filter machines typically consist of several key components that work together to achieve optimal filtration. These components include pre-filters, HEPA (High Efficiency Particulate Air) filters, activated carbon filters, and sometimes UV-C light for sterilization purposes. The pre-filters capture larger particles, extending the life of the HEPA filters, which are designed to filter out particles as small as 0.3 microns with an efficiency of 99.97%. Activated carbon filters are utilized to absorb gases and odors, making air not just cleaner but also more pleasant to breathe.

Manufacturing Process

The manufacturing process for air filter machines begins with robust research and development. Engineers work to design machines that are not only effective in pollution control but also energy-efficient and user-friendly. Once a prototype is developed, it undergoes rigorous testing to ensure it meets safety and performance standards.

air filter machine making products

The assembly line then begins, where materials such as high-grade metal, plastics, and filter media are carefully sourced and assembled. Advanced technologies, such as automation and robotics, play a significant role in streamlining production, ensuring consistency, and reducing the likelihood of human error. Quality control is vital throughout the production process to ensure that each machine meets industry standards.

Market Demand and Trends

The demand for air filter machines has surged in recent years, predominantly due to rising awareness about health implications associated with poor air quality. Factors such as climate change, increased pollution levels, and the lingering effects of global events like the COVID-19 pandemic have further driven the need for efficient air filtration systems.

Moreover, the latest trends in the industry include the development of smart air filter machines equipped with IoT technology, allowing users to monitor air quality remotely and receive real-time updates on filter statuses. This not only enhances the user experience but also promotes proactive maintenance, ensuring the longevity of the machines.

Conclusion

In conclusion, the manufacturing of air filter machines is vital for improving air quality standards across various industries. As technology advances and awareness grows, the need for effective air filtration solutions will only increase. Investing in the production and development of these machines is not just a business opportunity; it is a commitment to creating a healthier and safer environment for everyone.

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025