Aug . 04, 2024 00:42 Back to list

Automated Casting Solutions for Efficient Seal Packing in Filter Element Manufacturing Processes

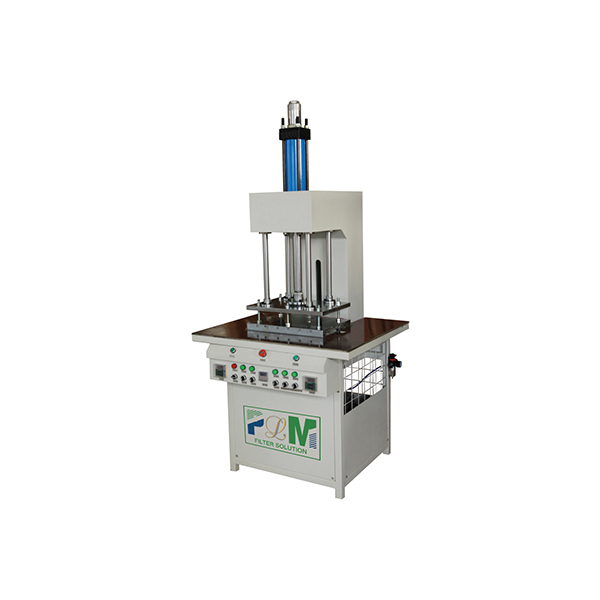

The Role of PU-20F Full-Auto Casting Machine in Seal Packing for Filter Element Companies

In the rapidly evolving landscape of manufacturing technology, efficiency and precision are paramount. Particularly within the filter element industry, where stringent quality standards dictate the success of products, innovations such as the PU-20F Full-Auto Casting Machine are making significant impacts. This article explores the importance of such machines in seal packing processes and their role in enhancing operational efficiency, product quality, and overall competitiveness in the market.

The PU-20F Full-Auto Casting Machine represents a state-of-the-art solution for the production of filter elements, especially in the sealing process. Typically, filter elements consist of multiple components that must be tightly sealed to ensure their functionality and durability. A robust seal not only enhances the filter's performance but also prolongs its life, which is a crucial aspect for clients in various industries, including automotive, aerospace, and manufacturing. The PU-20F machine automates the sealing process, significantly reducing the manual labor involved and minimizing the chances of human error.

One of the standout features of the PU-20F machine is its speed and efficiency. The full-automatic design allows it to operate continuously, producing a large volume of high-quality sealed filter elements in a fraction of the time it would take a manual operation. This not only accelerates production rates but also enables companies to respond more swiftly to market demands. In industries where time-to-market is critical, such adaptability can be a substantial competitive advantage.

Precision is another critical aspect of the casting process in filter element manufacturing. The PU-20F’s advanced technology ensures that each seal is crafted with exact specifications, delivering uniformity across batches. Uniformity in sealing translates to reliability in performance, which is essential for the credibility of filter elements in the market. Clients are less likely to experience issues such as leaks or failures with products manufactured using precise automation, thus fostering trust and long-term relationships.

pu-20f full-auto casting machine on seal packing in filter element companies

Moreover, the PU-20F Full-Auto Casting Machine integrates seamlessly with other manufacturing processes, allowing for better workflow management. Its compatibility with industrial automation systems means that companies can track production metrics, maintain quality control, and even implement predictive maintenance protocols. This level of integration not only streamlines operations but also significantly reduces downtime, which is a crucial factor in maintaining profitability.

Cost-effectiveness is another advantage that businesses gain through the adoption of the PU-20F machine. While the initial investment might appear substantial, the long-term savings through reduced labor costs, decreased waste due to fewer errors, and lower operational costs present a compelling case. As filter element manufacturers strive to maintain their margins amid rising raw material costs, investing in efficient technologies like the PU-20F full-auto machine becomes a strategic decision.

Lastly, sustainability is an increasingly vital concern in manufacturing today. The PU-20F machine is designed with energy efficiency in mind, which not only decreases operational costs but also aligns with the sustainable practices that many businesses are now prioritizing. Companies employing such environmentally considerate practices are better positioned to meet regulatory requirements and appeal to eco-conscious consumers.

In conclusion, the PU-20F Full-Auto Casting Machine is transforming the seal packing process in filter element companies. By enhancing efficiency, precision, and integration, while also supporting cost-effective and sustainable manufacturing practices, these machines empower companies to improve their product offerings and service delivery. As manufacturing continues to advance, embracing such innovative technologies will be essential for businesses aiming to stay ahead in the competitive landscape.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025