Sep . 27, 2024 19:32 Back to list

Efficient HEPA Filter Production Equipment for Superior Air Purification Solutions

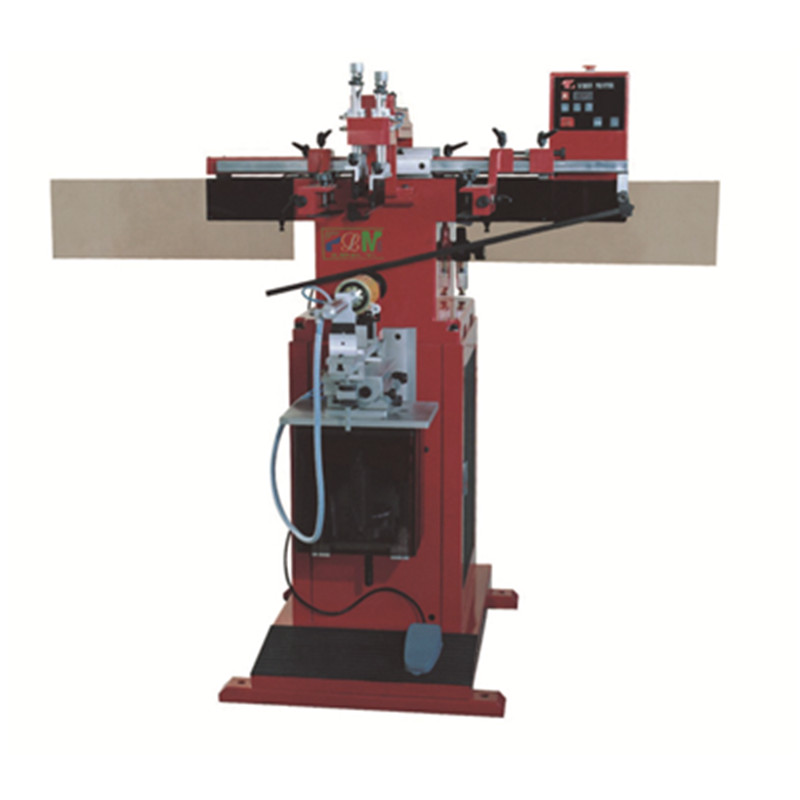

The Best HEPA Filter Making Machine A Comprehensive Overview

High-Efficiency Particulate Air (HEPA) filters have become a vital component in numerous applications, from air purifiers and industrial ventilation systems to vacuum cleaners and medical facilities. The rising demand for clean air solutions has led to an increase in the production of HEPA filters, prompting the need for efficient and reliable manufacturing processes. In this light, selecting the best HEPA filter making machine has become an essential undertaking for manufacturers aiming to provide high-quality products. This article explores the features and considerations that define the best HEPA filter making machine, along with its benefits and potential impact on the industry.

Understanding HEPA Filters

Before delving into manufacturing machinery, it is necessary to understand what HEPA filters are and their significance. HEPA filters are designed to trap particles as small as 0.3 microns with an efficiency of 99.97%. They are crucial in environments where air quality is essential, such as hospitals, laboratories, and homes with allergies or asthma sufferers. Consequently, the production of HEPA filters must comply with specific regulatory standards, ensuring they meet performance expectations.

Key Features of a High-Quality HEPA Filter Making Machine

1. Precision Engineering The best HEPA filter making machines are equipped with high-precision components that enable the accurate cutting, folding, and assembling of filter media. This precision greatly influences the overall efficiency and efficacy of the final product.

2. Automation Automation in the manufacturing process minimizes human error and enhances productivity. A machine that incorporates advanced automation technology can streamline operations from raw material handling to the final packing of the filters, significantly reducing production time and costs.

3. Versatility HEPA filters come in various shapes and sizes for different applications. A versatile machine that can adapt to various filter designs without extensive reconfiguration can greatly benefit manufacturers by expanding their product range.

4. Ease of Maintenance Continuous production requires machines that are not only efficient but also easy to maintain. The best machines offer user-friendly interfaces, easy access to components, and built-in diagnostic tools to minimize downtime and maintenance costs.

best hepa filter making machine

5. Energy Efficiency With growing concerns over environmental sustainability, energy-efficient machines are becoming increasingly important. A HEPA filter making machine that uses less energy while maintaining high production output can significantly reduce operational costs and environmental impact.

The Benefits of Investing in a Quality HEPA Filter Making Machine

Investing in a high-quality HEPA filter making machine can yield numerous benefits for manufacturers. First and foremost, it enhances product quality, ensuring each filter meets stringent industry standards. Reliable machines also improve production efficiency, allowing manufacturers to fulfill market demands swiftly.

Moreover, the ability to produce a variety of filter types can open up new business opportunities. Manufacturers might cater to different sectors, including automotive, aerospace, and home appliances, thus diversifying their revenue streams. Additionally, a machine with lower operating costs can improve profit margins over time.

Choosing the Right HEPA Filter Making Machine

Selecting the right HEPA filter making machine involves several considerations, including production capacity, initial investment costs, and supplier support. It is crucial for manufacturers to conduct thorough research, read industry reviews, and possibly arrange for demonstrations before making a purchase.

Another essential factor is after-sales service. Reliable suppliers offering technical support, spare parts, and regular upgrades can make a significant difference in the long-term success of the manufacturing operation.

Conclusion

In conclusion, as the demand for clean air solutions continues to rise, the importance of efficient HEPA filter production cannot be overstated. Choosing the best HEPA filter making machine is a critical step for manufacturers looking to ensure product quality, efficiency, and sustainability. By focusing on precision, automation, versatility, maintenance ease, and energy efficiency, companies can position themselves for success in an increasingly competitive market. Ultimately, investing in the right equipment will enhance not only production capabilities but also the overall health and safety of the environments in which HEPA filters are utilized.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025