Nov . 24, 2024 16:11 Back to list

best plgt-600n full-auto rotary eco filter paper pleating production line

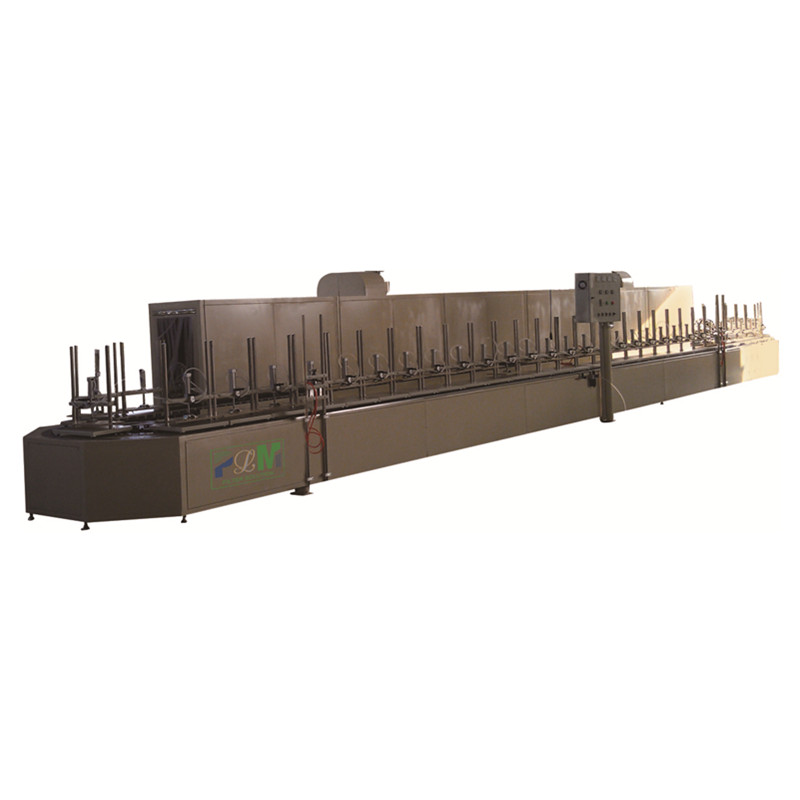

The Best PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line

In today’s fast-paced manufacturing environment, efficiency and sustainability are crucial. The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line stands out as a pivotal innovation in the filter paper industry, combining advanced technology with eco-friendly practices. Designed to meet the growing demands for high-quality filter paper products, this production line enhances productivity while minimizing environmental impact.

Advanced Technology

The PLGT-600N utilizes state-of-the-art automation technology, allowing for a seamless production process. This fully automated system reduces the need for manual labor, significantly lowering the risk of human error and enhancing overall efficiency. With its rotary design, the production line optimizes space utilization and speeds up the manufacturing process, yielding high output rates without sacrificing quality. It’s engineered to handle a variety of filter paper materials, providing versatility for manufacturers looking to diversify their product offerings.

Eco-Friendly Manufacturing

In an era where sustainability is paramount, the PLGT-600N distinguishes itself with its eco-friendly features. Designed with energy efficiency in mind, this production line consumes less power than traditional manufacturing methods, decreasing operational costs and reducing carbon emissions. The line employs biodegradable filter paper, promoting a circular economy by ensuring that the final product is not only efficient but also environmentally safe. The PLGT-600N aligns with global sustainability goals, making it an attractive option for companies aiming to enhance their green credentials.

best plgt-600n full-auto rotary eco filter paper pleating production line

Enhanced Product Quality

Quality assurance is a hallmark of the PLGT-600N. The integrated precision control systems monitor various parameters during production, ensuring that each batch meets stringent quality standards. The pleating process enhances the filter paper's efficiency, increasing its surface area and improving filtration performance. With consistent and reliable product quality, manufacturers can assure their clients of the effectiveness of their filter solutions, which is crucial for maintaining competitiveness in the market.

User-Friendly Operation

Despite its advanced technology, the PLGT-600N is designed for user-friendliness. The control panel features intuitive interfaces that allow operators to monitor the production process easily, make adjustments on the fly, and conduct troubleshooting without specialized training. This accessibility not only reduces downtime but also allows for a quicker return on investment, making it a smart choice for businesses looking to upgrade their manufacturing capabilities.

Conclusion

The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line represents a significant leap forward in filter paper manufacturing technology. With its combination of automation, eco-friendly practices, and commitment to quality, it empowers manufacturers to meet the increasing market demands while supporting sustainable development. Investing in this innovative production line is not just a step towards greater efficiency—it’s a strategic move towards a greener future in the filter paper industry. As the demand for high-quality and environmentally responsible products continues to grow, the PLGT-600N stands at the forefront, ready to lead the way.

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025