Sep . 02, 2024 11:40 Back to list

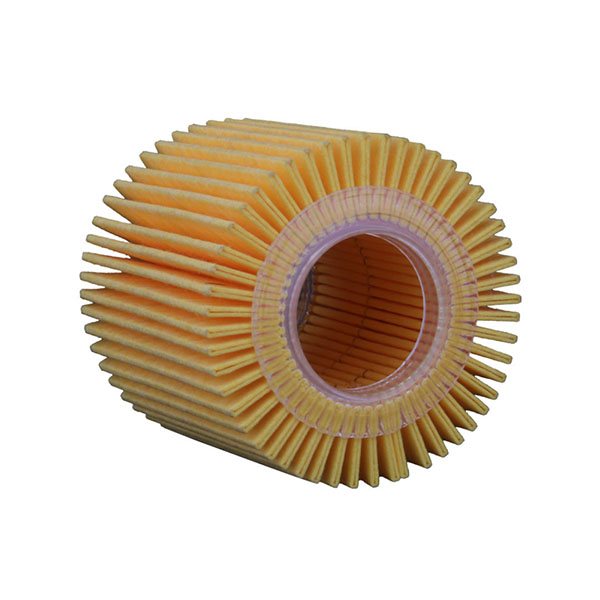

Buy Compressor Filter - High-Quality Filters for Optimal Performance

Understanding the Importance of Buying a Compressor Filter

When operating any pneumatic system or air compressor, the quality of the air produced is paramount. This is where compressor filters enter the scene. Whether you are running a small workshop or utilizing large-scale industrial equipment, understanding the crucial role that compressor filters play can significantly improve your operations and prolong the equipment’s lifespan.

What is a Compressor Filter? A compressor filter is a device designed to remove impurities from the air before it enters the compressor or the final application. These impurities can include dust, dirt, water, oil, and other contaminants, which can adversely affect the performance of pneumatic systems. The primary aim of using a compressor filter is to ensure that only clean, dry air is delivered, thus safeguarding your machinery and preventing costly damage or downtime.

Types of Compressor Filters There are several types of compressor filters available on the market, each designed for specific applications

1. Air Filters These are the first line of defense against particles and contaminants. They usually employ a network of fibers that trap dust and dirt.

2. Water Separators This type is crucial in preventing moisture from entering the air system, as excess water can cause corrosion and inefficient operation.

3. Oil Filters In systems that utilize oil injection, filters play a vital role in removing any oil leaks from the compressed air, ensuring that it remains clean.

buy compressor filter

4. Coalescing Filters These filters combine the functions of air and water separators and are excellent for removing microscopic droplets of water and oil from the air stream.

The Benefits of Using Compressor Filters Investing in a high-quality compressor filter is not just a matter of maintenance; it’s about ensuring optimal performance. Clean air leads to improved efficiency, which in turn results in energy savings. When contaminants are removed, the compressor doesn’t have to work as hard, leading to lower electricity costs and a reduced carbon footprint.

Moreover, using compressor filters extends the lifespan of your equipment. Dust and moisture can lead to wear and tear over time, resulting in frequent repairs or even the need for replacement. By effectively filtering the air, you reduce this risk, thus saving money on maintenance and repairs.

How to Choose the Right Compressor Filter When selecting a compressor filter, it’s essential to consider the specific requirements of your air system. Key factors to consider include

- Air Flow Rate Ensure the filter can handle the volume of air required. - Contaminant Type Identify what types of contaminants are common in your environment. - Space and Installation Consider the available space for the filter and the ease of installation. - Budget Weigh the initial costs against the potential savings in maintenance and energy efficiency.

Conclusion In summary, buying a compressor filter is a critical investment for any operation relying on compressed air. By ensuring air purity, these filters enhance performance, improve efficiency, and protect your valuable equipment. Taking the time to choose the right filter for your needs will pay dividends in both the short and long term. Prioritizing air quality will not only prolong the life of your compressor but also optimize your operations, making compressor filters an essential component of effective air management systems.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025