Nov . 05, 2024 20:41 Back to list

cabin air filter making machine manufacturer

The Role of Cabin Air Filter Making Machine Manufacturers

In today’s automotive industry, the importance of cabin air filters is often overlooked by consumers who mainly focus on engine components and exterior designs. However, as awareness of air quality and health issues rises, cabin air filters have gained significant attention. These filters are critical in ensuring that the air inside vehicles is clean and devoid of harmful pollutants. To meet the increasing demand for high-quality cabin air filters, the manufacturing process has evolved, necessitating specialized machinery. This is where cabin air filter making machine manufacturers come into play.

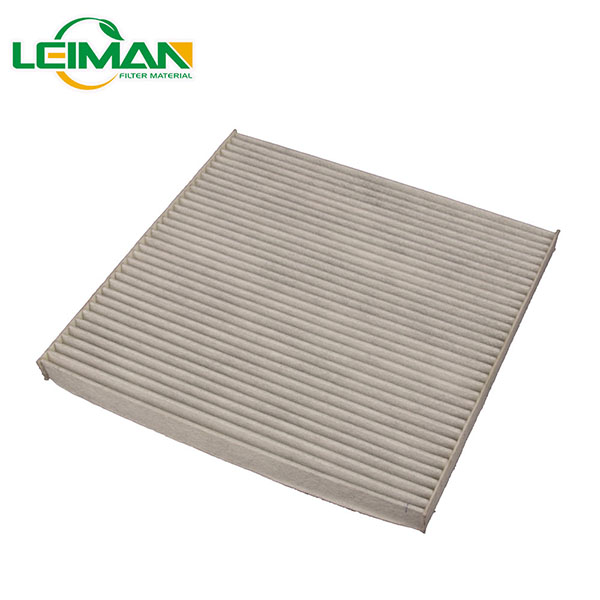

Understanding Cabin Air Filters

Cabin air filters play a vital role in maintaining a healthy environment within a vehicle. They filter out dust, pollen, mold spores, and harmful gases, ensuring that the air passengers breathe is clean. With the rise in air pollution and allergens, consumers are increasingly aware of the benefits of changing cabin air filters regularly. This heightened awareness has led to a surge in demand, pushing manufacturers to scale up production and innovate new filter-making processes.

The Role of Manufacturers

Cabin air filter making machine manufacturers are responsible for producing the equipment that automates the production of these vital components. The machines they create are tailored to meet the specific needs of manufacturers. For instance, they often produce machines that can fabricate filters in various sizes and materials, allowing for versatility in the final product. Additionally, they focus on increasing efficiency in the manufacturing process, reducing waste, and enhancing product quality.

Features of Modern Cabin Air Filter Making Machines

Modern cabin air filter making machines come equipped with advanced technologies that streamline production

. These features typically includecabin air filter making machine manufacturer

1. Automation Automation improves the efficiency of the manufacturing process, allowing for higher production rates and reducing labor costs. Many machines are equipped with robotic arms that handle tasks like cutting, folding, and assembling filters.

2. Precision Engineering High-quality filters require precise measurements and cuts. Machines are designed with state-of-the-art sensors and software that ensure every component is manufactured to exact specifications, which is crucial for maintaining the integrity of air filtration.

3. Material Compatibility Different filters require different materials. Current machines can handle a range of substrates, including activated carbon, HEPA materials, and synthetic fibers, thereby catering to diverse consumer needs.

4. Energy Efficiency With growing environmental concerns, many manufacturers are prioritizing energy-efficient machinery. New models consume less power while maintaining high output levels, aligning with sustainability practices.

Challenges in Production

Despite the technologies available, cabin air filter making machine manufacturers face numerous challenges. One significant issue is keeping up with regulatory changes related to air quality standards. Filters must meet increasingly stringent guidelines, requiring manufacturers to continually innovate. Furthermore, fluctuating raw material costs and supply chain disruptions can affect production timelines and costs.

Conclusion

Cabin air filter making machine manufacturers play a crucial role in the automotive industry by providing the necessary tools for producing high-quality filters. As environmental awareness grows and consumers demand cleaner air within their vehicles, the role of these manufacturers will become even more significant. Investing in advanced machinery not only ensures efficient production but also supports the creation of filters that contribute to healthier living conditions. In a world that prioritizes health and sustainability, the need for effective cabin air filter production is clear, and the manufacturers behind this equipment are at the forefront of this essential industry shift.

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025

-

Active Carbon Air Filter for Air Purifier – Superior Filtration Efficiency

NewsJul.27,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025