Nov . 12, 2024 01:39 Back to list

car pu air filter production line pricelist

The Car Air Filter Production Line A Comprehensive Overview of the Pricelist

The automotive industry has witnessed significant advancements in technology and production processes over the years, with one critical component being air filters. Car air filters are essential for maintaining engine performance and longevity by ensuring clean air is supplied to the engine. As demand for vehicles continues to grow globally, so does the need for efficient and cost-effective production lines for air filters.

When considering entering the air filter production market, prospective manufacturers must evaluate comprehensive pricelists that encompass various factors influencing overall costs. These may include machinery, raw materials, labor, and overhead expenses. This article will delve into the key components of a car air filter production line and provide insight into the associated costs.

Machinery and Equipment

The backbone of any production line is the machinery used to manufacture the product. In the case of air filters, the primary equipment includes cutting machines, pleating machines, bonding machines, and packaging systems. Depending on the scale of production, manufacturers can opt for fully automated systems or semi-automated setups.

1. Cutting Machines These are essential for preparing the filter media from rolls of material. Prices can vary significantly based on automation levels, ranging from $10,000 to $50,000.

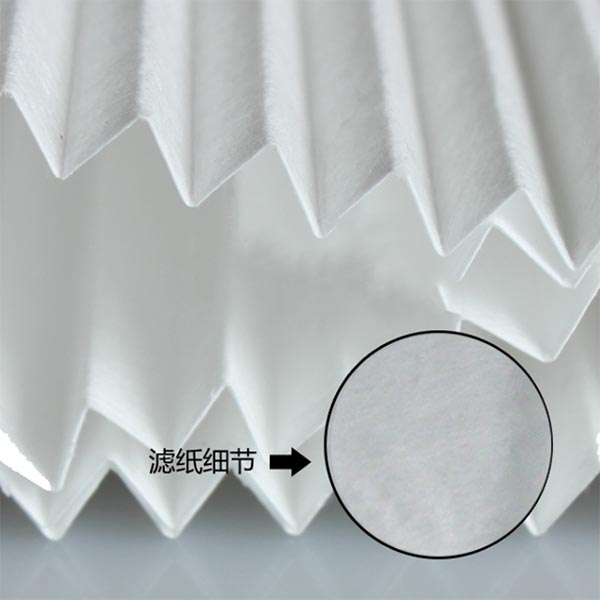

2. Pleating Machines This equipment folds the filter media into pleats, increasing the surface area for filtration. High-quality pleating machines can range from $20,000 to $100,000.

3. Bonding Machines Used to attach the pleated media to the filter frame, these machines are crucial for durability and effective performance. Costs can range from $5,000 to $30,000.

4. Packaging Systems To ensure the final product is ready for shipping, packaging equipment is necessary. Depending on the complexity and automation, prices can vary from $10,000 to $50,000.

The total investment in machinery can range from $55,000 to over $200,000, depending on the scale and level of automation

.car pu air filter production line pricelist

Raw Materials

The choice of raw materials significantly impacts the production cost and quality of air filters. Key materials include filter media (often composed of paper, foam, or synthetic fibers), frames (usually plastic or metal), and adhesives. Raw material costs will fluctuate based on market conditions, but on average

- Filter media can cost around $2 to $10 per square meter. - Frames may range from $0.50 to $5 each, depending on the material used. - Adhesives typically cost about $1 to $3 per liter.

Estimating raw material costs for a production run will depend on the scale of production and the specific design of the filters.

Labor Costs

Labor is another critical element in the cost of a production line. While automated systems can reduce the need for manual labor, trained staff is still required for quality control, machinery operation, and maintenance. Labor costs vary widely by region; in some areas, it may cost around $15 to $30 per hour for skilled labor.

Overhead Costs

Overhead expenses encompass utilities, rent, administrative costs, and maintenance. These costs can vary greatly depending on the location of the production facility and the scale of operations. On average, overhead can account for about 20-30% of total production costs.

Conclusion

In summary, establishing a car air filter production line requires careful consideration of various cost factors, including machinery, raw materials, labor, and overhead. A well-prepared pricelist is essential for budgeting and financial planning, ensuring that manufacturers can offer competitive prices while maintaining quality standards. As the automotive market continues to expand, the demand for efficient air filter production lines will undoubtedly persist, presenting opportunities for innovative manufacturers to thrive in this vital niche.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025