Nov . 12, 2024 13:07 Back to list

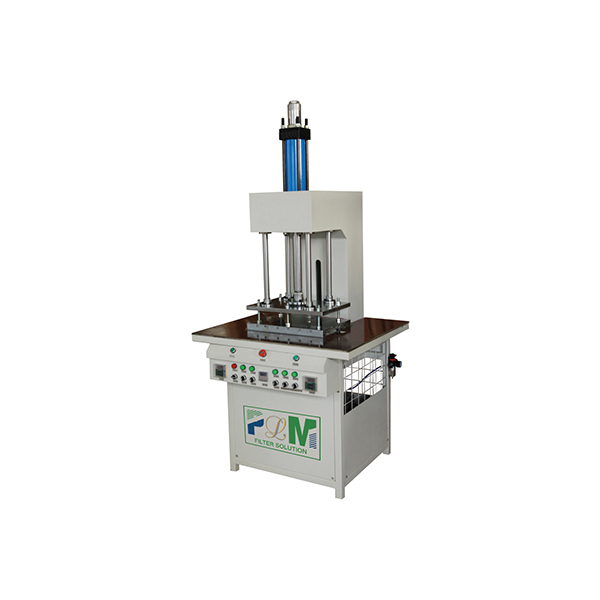

cheap pljl-4b four-station seal leakage tester for spin-on filter

Exploring the Low-Cost PLJL-4B Four-Station Seal Leakage Tester for Spin-On Filters

In the automotive and manufacturing industries, ensuring the integrity of components is crucial. One such component, the spin-on filter, plays a vital role in maintaining the health of an engine. To guarantee that these filters function effectively, manufacturers and quality control professionals turn to specialized testing equipment. Among the options available, the PLJL-4B four-station seal leakage tester stands out as an accessible and efficient solution.

What is the PLJL-4B Seal Leakage Tester?

The PLJL-4B is designed specifically for testing the seal integrity of spin-on filters. It features four testing stations, allowing for simultaneous inspection of multiple units. By using this device, manufacturers can quickly assess whether filters are properly sealed and capable of withstanding the pressures they will encounter in real-world applications. The device is particularly beneficial for quality assurance teams, as it reduces downtime and enhances productivity.

Key Features and Specifications

One of the most critical aspects of the PLJL-4B tester is its affordability. With a low-cost design, it makes advanced leak testing accessible to smaller manufacturers or workshops that might otherwise have to compromise on quality assurance due to budget constraints. Despite its economical price, the PLJL-4B is loaded with features that ensure reliable and accurate testing

1. Four-Station Capacity Allows multiple spin-on filters to be tested simultaneously, improving throughput and efficiency in manufacturing processes. 2. User-Friendly Interface The tester typically comes with an intuitive control panel that simplifies operation, reducing the learning curve for new users.

3. Adjustable Testing Parameters Users can customize the testing conditions based on the specifications of the filters being tested, ensuring more relevant results.

cheap pljl-4b four-station seal leakage tester for spin-on filter

5. Real-Time Results The PLJL-4B provides immediate feedback on the integrity of the seals. This quick turnaround is essential for making timely adjustments to production lines or identifying faulty batches.

Importance of Leak Testing for Spin-On Filters

Spin-on filters are essential in various applications, particularly in automotive and industrial machinery. A compromised seal can lead to significant problems, including oil leaks, decreased engine performance, and even catastrophic failures. Therefore, maintaining rigorous quality control measures through reliable testing is vital. The PLJL-4B’s ability to quickly and effectively identify leaks before filters reach the market can prevent costly recalls and protect a manufacturer’s reputation.

Applications Across Industries

While primarily used in automotive filter manufacturing, the versatility of the PLJL-4B enables its application across various sectors, including

- Oil and Gas Ensuring the integrity of filters used in processing equipment. - Manufacturing Testing filters in hydraulic systems to prevent malfunctions. - Aerospace Maintaining stringent safety standards in filter sealing.

By capitalizing on the PLJL-4B’s capabilities, companies in these fields can enhance their overall product quality and operational efficiency.

Conclusion

The PLJL-4B four-station seal leakage tester for spin-on filters represents an ideal solution for manufacturers looking to enhance their quality control processes without incurring excessive costs. Its combination of affordability, efficiency, and robust design makes it a valuable asset in ensuring that essential components meet safety and performance standards. As industries continue to prioritize quality and reliability, tools like the PLJL-4B will play a critical role in shaping the future of manufacturing and maintaining the integrity of essential automotive components. Investing in such technology not only streamlines production but also safeguards businesses against the repercussions of defects and failures, ultimately contributing to stronger customer trust and satisfaction.

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025