Dec . 03, 2024 18:11 Back to list

compress air filter making machine exporter

The Rising Demand for Compressed Air Filter Making Machines A Focus on Exporter Opportunities

In the increasingly industrialized and manufacturing-driven world, compressed air is a fundamental resource utilized across various sectors, including automotive, food and beverage, pharmaceuticals, and electronics. Given its critical role in operations, the need for high-quality compressed air filters is more important than ever. Consequently, the market for compressed air filter making machines is witnessing a significant surge, presenting lucrative opportunities for exporters in this domain.

Understanding Compressed Air Filters

Compressed air filters are essential for ensuring that the air used in manufacturing processes is free from contaminants, such as water, oil, dust, and other particulates. These contaminants can significantly affect product quality and operational efficiency. For instance, in the food and beverage industry, the presence of impurities in compressed air can lead to contamination of products, resulting in recalls and loss of consumer trust. Similarly, in the electronics sector, clean compressed air is vital for the precise manufacturing of components. Therefore, investing in efficient compressed air filter technology is crucial.

The Role of Compressed Air Filter Making Machines

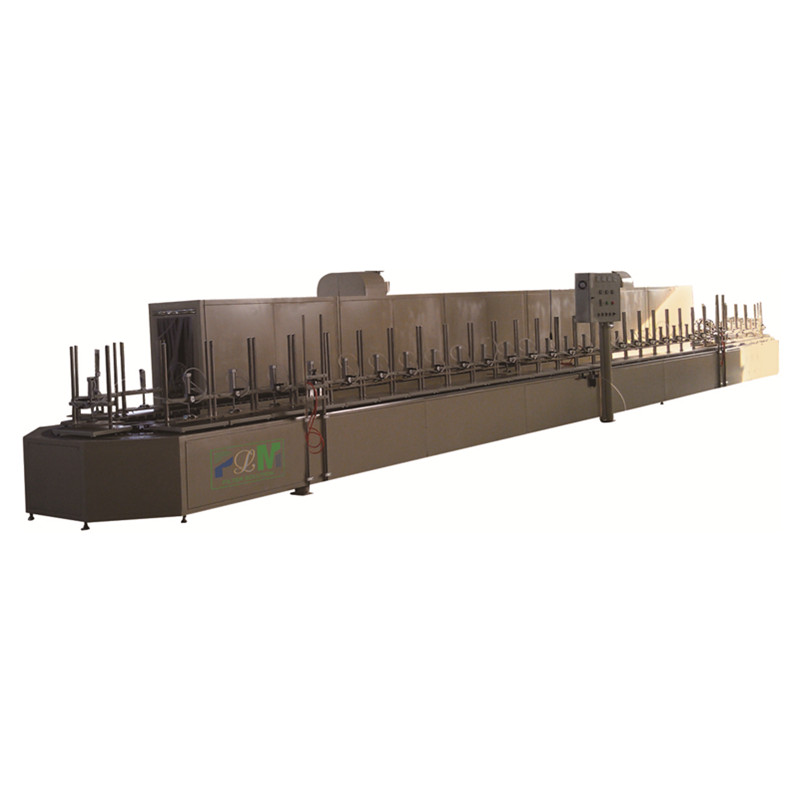

To meet the demand for high-quality filters, manufacturers are increasingly turning to specialized equipment that can produce these filters at scale. Compressed air filter making machines are designed to fabricate various types of filters, including particulate filters, coalescing filters, and activated carbon filters. These machines leverage advanced technologies, such as automated production lines, precision cutting, and advanced filtration media application, to ensure consistent quality and efficiency in the manufacturing process.

Exporter Opportunities in the Compressed Air Filter Making Machine Market

As industries globally intensify their focus on quality and efficiency, the demand for compressed air filter making machines is on the rise. This creates numerous opportunities for exporters in this niche market. Different regions across the globe exhibit distinct requirements and compliance standards for compressed air solutions, making a nuanced understanding of the target market crucial for successful exports.

compress air filter making machine exporter

1. Diverse Market Needs Different industries have varying specifications related to filter quality, size, and type. Exporters can capitalize on this diversity by tailoring their offerings to meet specific market requirements. For instance, industries in Europe may prioritize energy efficiency and sustainability, while emerging markets in Asia might focus on cost-effectiveness and production volume.

2. Technological Advancements The evolution of technology in manufacturing processes presents another avenue for exporters. By investing in research and development, manufacturers can produce cutting-edge machines that improve efficiency and reduce operational costs for their users. Exporters equipped with innovative solutions can differentiate themselves in a competitive market.

3. Sustainability Matters With increasing awareness of environmental issues, many industries are seeking sustainable solutions. Exporters who can provide eco-friendly compressed air filter making machines that align with green manufacturing practices can gain a competitive edge. This includes machines that reduce energy consumption and waste generation during production.

4. After-Sales Support and Services Establishing a reputation for excellent after-sales service can enhance an exporter’s appeal. Providing customers with installation support, maintenance services, and easy access to spare parts can foster long-term relationships and repeat business.

5. Access to Emerging Markets Many developing regions are ramping up their industrial capabilities, creating a burgeoning market for manufacturing equipment, including compressed air filter making machines. Identifying and entering these markets early can allow exporters to establish a strong foothold before competition intensifies.

Conclusion

The global demand for compressed air filter making machines is growing, driven by the expanding industrial landscape and the critical need for clean production environments. Exporters who can effectively navigate market nuances, leverage technological advancements, offer sustainable solutions, and provide outstanding customer support will find themselves well-positioned in this thriving sector. The future is bright for those ready to embrace the opportunities in the compressed air filter manufacturing industry, ensuring that businesses around the world continue to operate efficiently and safely.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025