Aug . 17, 2024 11:05 Back to list

Digital Filter Paper Porosity Tester for Accurate Measurement and Quality Control

Understanding the Importance of Digital Filter Paper Porosity Testing Instruments

In various scientific and industrial applications, the quality and performance of filter paper are crucial. One of the key characteristics that define filter paper's efficacy is its porosity, which influences how well it can perform filtration tasks. To ensure filter papers meet stringent quality criteria, reliable testing instruments are essential. Among these, the digital filter paper porosity testing instrument stands out for its precision and ease of use.

What is Porosity?

Porosity refers to the void spaces or pores within a material, which directly affects its ability to allow fluids to pass through or retain them. In the context of filter paper, porosity dictates the flow rate of liquids, the size of particles that can be filtered out, and the overall filtration efficiency. High porosity often leads to faster filtration speeds, while low porosity can enhance the filtration of finer particles.

The Role of Digital Filter Paper Porosity Testing Instruments

Digital filter paper porosity testing instruments are designed to measure the porosity of filter paper accurately and reproducibly. These instruments use sophisticated technology to provide detailed measurements, ensuring that manufacturers and users can assess the quality of their filter papers with confidence.

1. Accuracy and Precision One of the primary benefits of digital testing instruments is the improved accuracy and precision of results compared to traditional methods. Manual testing can introduce human error, while digital devices minimize this risk by providing automated readings.

2. User-Friendly Interface Modern digital testing instruments often feature intuitive interfaces that allow users to operate the machines easily, even if they lack extensive technical knowledge. This accessibility makes it easier for businesses of all sizes to incorporate porosity testing into their quality control processes.

buy plag-461e digital filter paper porosity testing instrument

3. Data Recording and Analysis Many digital filter paper porosity testing instruments come equipped with software that can record data over time. This feature is invaluable for identifying trends in paper quality, making it easier to comply with industry standards and improve manufacturing processes. Users can generate reports and analyze data with just a few clicks, enhancing the decision-making process.

4. Portability and Versatility Some digital porosity testing instruments are designed to be portable, allowing for on-site testing. This flexibility can be particularly beneficial for companies that require immediate results without sending samples to a laboratory.

Applications of Porosity Testing Instruments

The applications for filter paper porosity testing are vast. In laboratories, researchers rely on accurate measurements to ensure that filter papers meet specific criteria for various experiments. In manufacturing, companies must consistently test paper to uphold quality standards and facilitate continuous improvement. Additionally, industries such as pharmaceuticals, food and beverage, and environmental monitoring utilize these instruments to guarantee that their products meet regulatory requirements.

Conclusion

Digital filter paper porosity testing instruments play an essential role in ensuring the quality and reliability of filter materials used across various industries. With their ability to provide accurate and fast measurements, these instruments contribute significantly to the overall effectiveness of filtration processes. As technology continues to advance, the importance of such instruments will only grow, solidifying their place in the quality control measures of many businesses.

Investing in a digital filter paper porosity testing instrument not only enhances product quality but also supports regulatory compliance and operational efficiency. For any organization involved in the production or application of filter paper, incorporating such a device into their testing arsenal is a prudent step towards achieving excellence in filtration solutions.

-

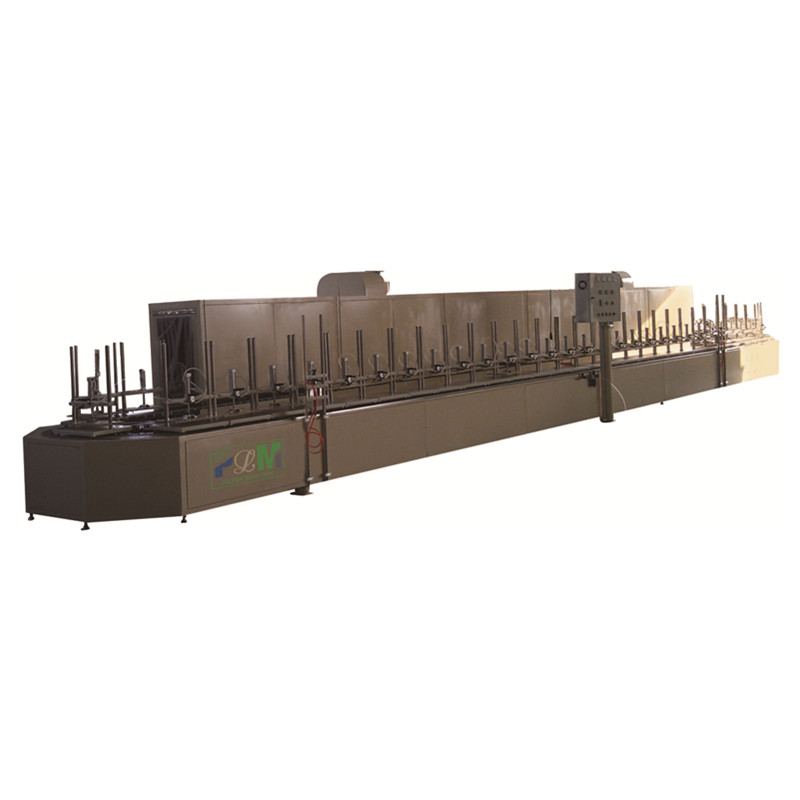

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.16,2025

-

PLAB-6 A/B Two-Component Filter Gluing Machine - Hebei Filter Man | Precision, Efficiency

NewsAug.16,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Adjustable Speed, Step Motor, Heat Mixing

NewsAug.16,2025

-

Eco-Friendly Coffee Filter Paper: Pure Taste, Sustainable Choice

NewsAug.16,2025

-

PLAB-6 Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025