Aug . 09, 2024 21:40 Back to list

Digital Filter Technology for Assessing Porosity in Testing Instruments and Manufacturers

Understanding the Importance of Paper Porosity Testing Instruments in Digital Filtering

In the realm of manufacturing and quality control, paper porosity is a crucial property that can significantly affect the functionality of various products, especially those involving filtration processes. With the advent of modern technologies, digital filter paper porosity testing instruments have emerged as invaluable tools for manufacturers seeking to ensure the quality of their products.

What is Paper Porosity?

Paper porosity refers to the ability of paper to allow air or liquids to pass through its structure. This property is influenced by the paper's composition, density, and thickness. In industries such as food packaging, pharmaceuticals, and chemicals, controlling porosity ensures optimal filtration, preventing contaminants from passing through while allowing the desired substances to permeate.

The Role of Digital Filter Paper Porosity Testing Instruments

Digital filter paper porosity testing instruments are designed to provide precise and reliable measurements of porosity in various types of paper. These instruments utilize advanced digital technology to measure parameters such as air permeability and liquid absorption rates. By assessing these characteristics, manufacturers can determine how well a specific type of paper will perform in real-world applications.

Accuracy and Efficiency

One of the primary advantages of digital porosity testing instruments is their accuracy. Unlike traditional methods, which can be labor-intensive and time-consuming, digital devices offer quick and precise readings. This efficiency translates to reduced testing times and improved throughput in manufacturing environments, allowing companies to maintain stringent quality control without slowing down production.

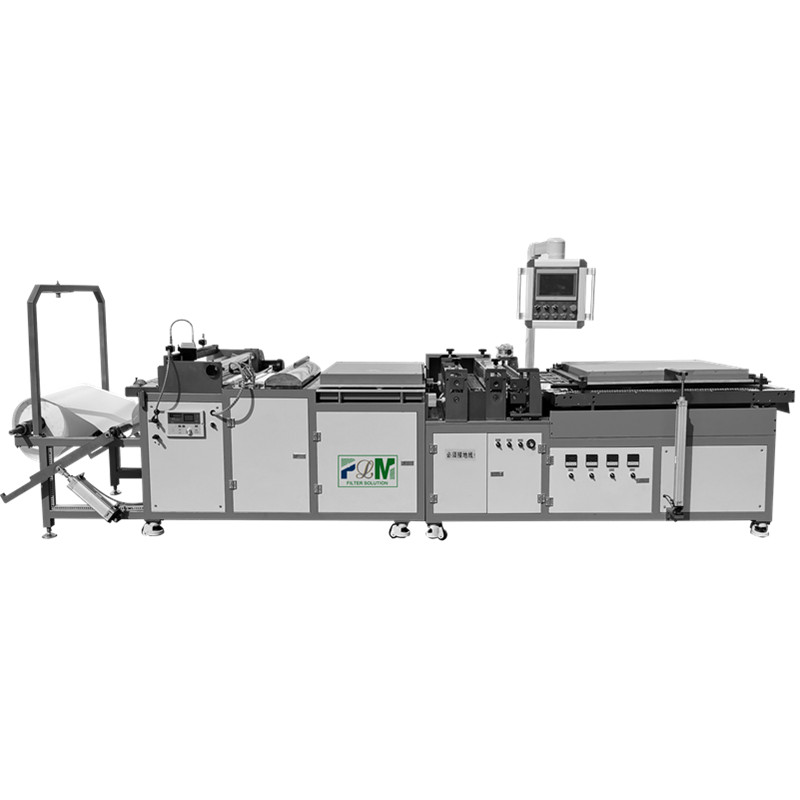

plag-461e digital filter paper porosity testing instrument manufacturers

User-Friendly Interface

Modern testing instruments often come equipped with user-friendly interfaces, making it easier for operators to conduct tests and interpret results. Features such as touchscreens, graphical displays, and software integration streamline the process, reducing the need for specialized training. This accessibility ensures that more personnel can engage in quality control without extensive technical backgrounds.

Applications of Paper Porosity Testing

The applications of paper porosity testing instruments extend across various industries. In the food industry, for example, the porosity of packaging materials can affect the shelf life and safety of products. In pharmaceuticals, ensuring the proper porosity of filter papers used in drug formulation can prevent contamination, ensuring product efficacy.

Additionally, in the electronics sector, the porosity of materials used in capacitors and insulators can influence the performance and reliability of devices. Hence, testing the porosity of papers used in these applications is critical for manufacturers aiming to deliver high-quality products.

Conclusion

As industries strive for higher standards of quality and safety, the importance of precise testing instruments cannot be understated. Digital filter paper porosity testing instruments have become essential tools for manufacturers, enabling them to assess the properties of their products accurately and efficiently. By investing in these advanced technologies, companies can enhance their quality control processes, reduce waste, and ultimately improve customer satisfaction.

In a competitive market, the ability to provide consistent and reliable products gives manufacturers a significant edge. Therefore, understanding and utilizing digital filter paper porosity testing instruments is not just an option but a necessity for those committed to excellence in manufacturing and product development.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025