Aug . 19, 2024 01:53 Back to list

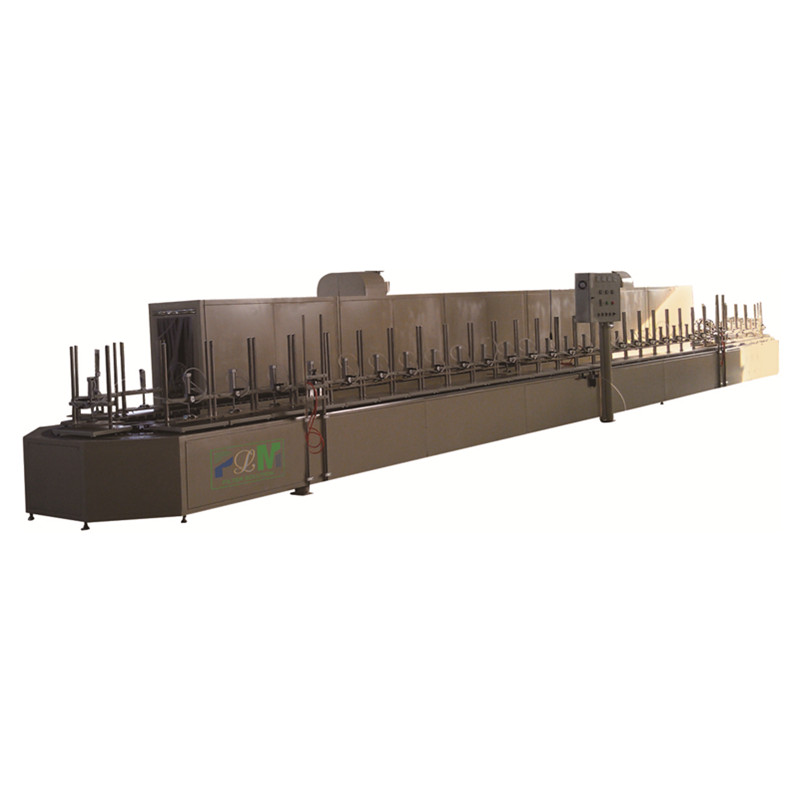

Discounted Filter Paper Production Equipment for Efficient Manufacturing Solutions

Understanding Discount Filters in Paper Making Machines

In the paper making industry, efficiency, quality, and cost-effectiveness are paramount for manufacturers striving to maintain a competitive edge. Among the various components that contribute to the effectiveness of paper production, discount filters stand out as crucial elements in enhancing product quality while also providing economic benefits. This article explores the significance of discount filters in paper making machines, outlining their functions, benefits, and impact on the overall production process.

The Role of Filters in Paper Making

At its core, the paper making process involves the transformation of raw materials, typically wood pulp, into sheets of paper through a series of mechanical and chemical processes. During this intricate procedure, certain contaminants and impurities can arise, such as wood fibers, fillers, and other substances that affect the quality of the final product. This is where discount filters come into play.

Discount filters are specifically designed to remove these unwanted particles and ensure that the pulp entering the paper machine is clean and of high quality. By effectively filtering out impurities, these devices help in achieving consistent thickness, color, and texture of the final paper product.

Types of Discount Filters

There are several types of filters utilized in paper making machines, including disc filters, rotary drum filters, and pressure screens

. Each type serves a unique purpose and is designed to cater to different stages of the paper making process.1. Disc Filters These are widely used for thickening the pulp. They operate by utilizing a series of discs that rotate in a tank filled with slurry. As the discs turn, water is drawn away, leaving a thicker pulp behind.

discount filter paper making machines

2. Rotary Drum Filters These filters utilize a cylindrical drum covered with a filtering medium. As the drum spins, it separates solid particles from the liquid by applying vacuum pressure. This ensures that impurities are efficiently removed from the pulp.

3. Pressure Screens Utilizing a pressure differential, these screens effectively filter out contaminants while allowing clean pulp to pass through. They are particularly useful in the final stages of pulp preparation, ensuring that all remaining impurities are eliminated before the pulp is formed into sheets.

Benefits of Using Discount Filters

Investing in high-quality discount filters brings numerous benefits to paper making facilities. Firstly, they enhance the quality of the final paper product by removing unwanted materials that can affect strength and appearance. This, in turn, leads to higher customer satisfaction and potentially opens up new markets for premium products.

Secondly, efficient filtering processes can lead to significant cost savings. By minimizing the amount of waste generated during production, manufacturers can optimize their raw material usage. Additionally, reducing waste leads to lower disposal costs and less environmental impact, aligning with the increasing demand for sustainable manufacturing practices.

Conclusion

In conclusion, discount filters are essential components in the paper making process. By ensuring the purity and quality of the pulp, these filters not only enhance the final product but also contribute to the economic efficiency of manufacturing operations. As the paper industry continues to evolve and adapt to new challenges, the importance of effective filtering solutions will only grow. Manufacturers who prioritize the quality of their filtering systems can expect to see improved product quality, reduced production costs, and a strengthened position in the competitive marketplace. Thus, investing in the right discount filter technology is not just a matter of compliance, but a strategic decision that can shape the future of paper production.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025