Aug . 07, 2024 17:30 Back to list

Effective Air Filters for High-Quality Compressor Performance and Enhanced Filtration Solutions

The Importance of High-Quality Compressor Air Filters

In industrial and commercial settings, air compressors play a crucial role in powering various machinery and tools. However, the effectiveness and longevity of these compressors largely depend on the quality of the air filters used. High-quality compressor air filters are essential for ensuring the efficient operation of the equipment, maintaining product quality, and lowering operational costs.

What Are Compressor Air Filters?

Compressor air filters are designed to remove contaminants from the air before it enters the compressor system. These contaminants can include dust, pollen, moisture, and oil particles that can significantly affect the performance and efficiency of the compressor. When unfiltered air enters the compressor, it can lead to a range of issues, including excessive wear and tear, overheating, and reduced efficiency. Thus, the role of the air filter is vital.

Benefits of High-Quality Air Filters

1. Enhanced Performance High-quality air filters ensure that clean air enters the compressor, which is essential for optimum performance. Clean air means that the compressor can operate at its best, providing consistent pressure and output without interruptions.

2. Increased Longevity Using a superior compressor air filter can significantly extend the lifespan of the compressor. By preventing harmful particles from entering the system, these filters reduce the risk of damage and wear, which can lead to costly repairs or replacements.

3. Energy Efficiency A compressor that operates with clean air is inherently more energy-efficient. High-quality filters minimize the strain on the compressor, allowing it to operate using less energy. Over time, this can translate into substantial cost savings on energy bills, making it a smart investment for any business.

4. Improved Air Quality In applications where air quality is paramount—such as in food and beverage production, pharmaceuticals, and electronics manufacturing—high-quality filters are crucial. They help ensure that the air is free from contaminants, which can compromise product cleanliness and safety.

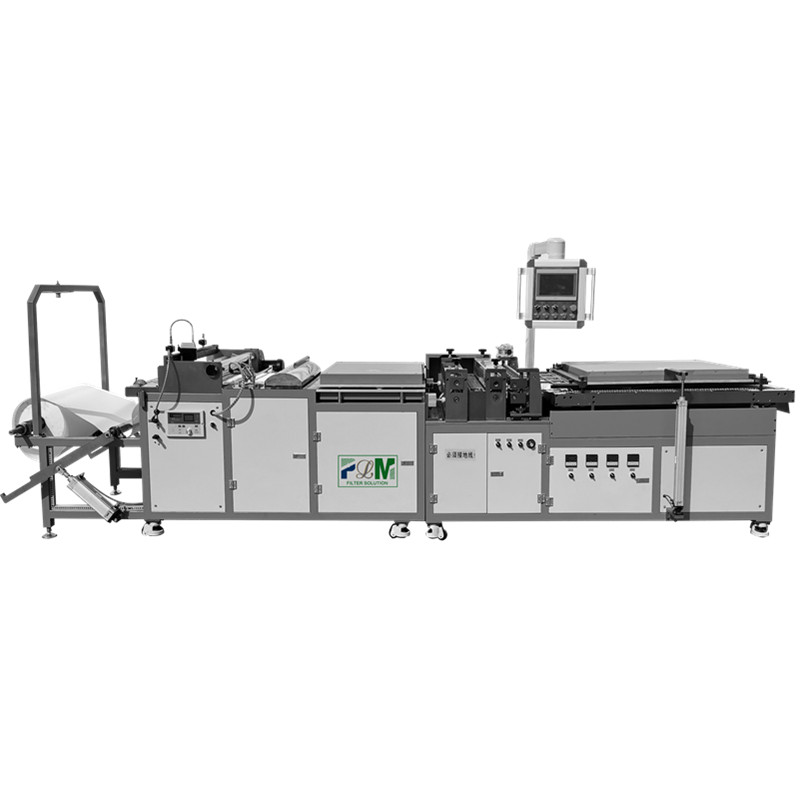

high quality compressor air filter

5. Environmental Impact Investing in high-quality compressor air filters can also have a positive impact on the environment. Efficient filters help reduce energy consumption, and by avoiding the premature disposal of compressors, they contribute to waste reduction.

Types of Compressor Air Filters

There are several types of air filters available, each serving different purposes. The most common types include

- Particulate Filters These filters capture solid particles like dust and dirt. They are typically the first line of defense against airborne contaminants. - Coalescing Filters These are designed to remove both water and oil vapor from the compressed air. They are critical in environments where moisture control is essential.

- Activated Carbon Filters These filters go a step further to remove odors and other gaseous contaminants from the air, providing a higher level of purity.

Choosing the Right Air Filter

When selecting a high-quality compressor air filter, it is essential to consider factors such as compatibility with the compressor model, application requirements, and the specific contaminants that need to be filtered. Working with reputable suppliers and manufacturers can provide insight into the best options tailored to a company's specific needs.

Conclusion

In conclusion, high-quality compressor air filters are not just accessories; they are integral components that can significantly impact the performance, longevity, and efficiency of air compressors. By investing in the right filtration systems, businesses can ensure that their compressors operate at optimal levels, leading to enhanced productivity and cost savings. Prioritizing air quality not only benefits operational efficiency but also promotes sustainability and product integrity. Thus, businesses must recognize the importance of these filters and choose wisely when it comes to their compressor maintenance strategy.

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.16,2025

-

PLAB-6 A/B Two-Component Filter Gluing Machine - Hebei Filter Man | Precision, Efficiency

NewsAug.16,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Adjustable Speed, Step Motor, Heat Mixing

NewsAug.16,2025

-

Eco-Friendly Coffee Filter Paper: Pure Taste, Sustainable Choice

NewsAug.16,2025

-

PLAB-6 Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025