Sep . 18, 2025 04:40 Back to list

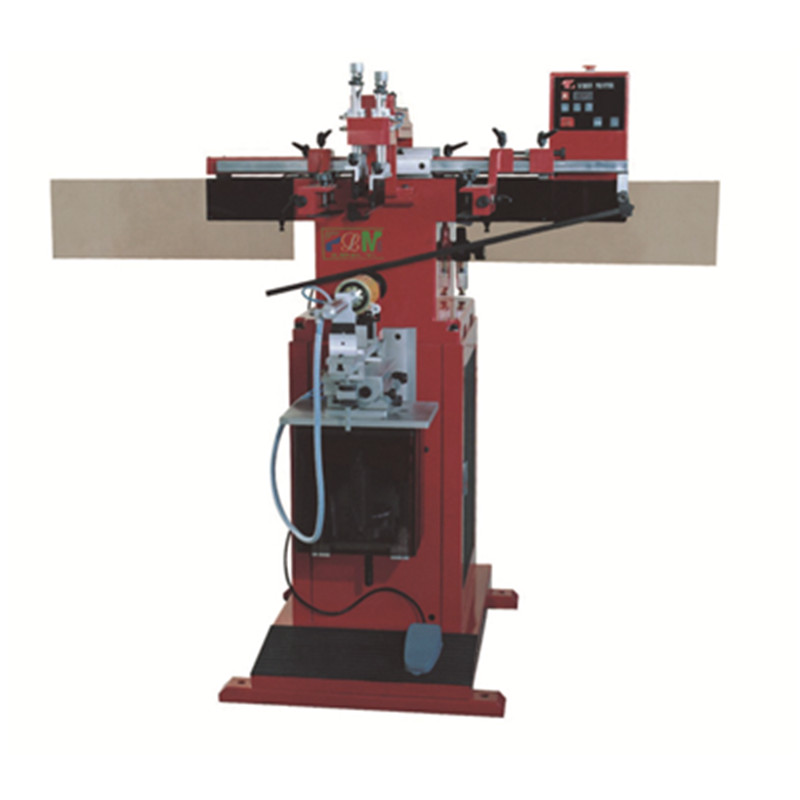

Efficient PP Spun Filter Cartridge Making Machine - High Quality

Navigating the Future of Automotive Filtration: Insights from the 135th Canton Fair

The 135th Canton Fair, a beacon of global trade and innovation, recently convened, drawing in a vast array of B2B decision-makers eager to explore the forefront of various industries. For the auto parts and filter element sector, this event was particularly pivotal. Exhibitors, including the esteemed Hebei Filter Man Automotive Parts Trading Co., Ltd, seized the opportunity to showcase a comprehensive range of cutting-edge automotive filtration solutions, aiming to forge new international distribution partnerships and connect with bulk buyers worldwide. This premier exhibition underscored the dynamic evolution of the industry, highlighting advancements that are set to redefine vehicle performance, sustainability, and occupant well-being.

The Fair served as an invaluable platform, offering deep dives into technological innovations, supply chain efficiencies, and market trends shaping the global auto parts and filter element landscape. From showcasing the precision of a professional air filter making machine to demonstrating the efficiency of a paper folding machine for air filter, the emphasis was clearly on quality and advanced manufacturing. For buyers and partners, it was an unparalleled chance to scout for reliable suppliers, understand emerging demands, and strategize for future growth in a rapidly changing automotive world.

Industry Trend Spotlight: Riding the Wave of Filtration Innovation

The automotive filtration industry is undergoing a transformative period, driven by a confluence of environmental regulations, technological advancements, and shifting consumer expectations. A significant trend observed at the Canton Fair was the escalating global attention on the demand for high-performance and eco-friendly filters. Manufacturers are increasingly focusing on materials and designs that not only enhance filtration efficiency but also minimize environmental impact throughout their lifecycle.

Advanced cabin air filtration systems are another area of rapid growth. With health and well-being becoming paramount, there's a strong push for filters featuring HEPA and anti-viral capabilities, designed to protect occupants from pollutants, allergens, and airborne pathogens. This innovation is supported by state-of-the-art production methods, utilizing sophisticated equipment like a car air filter making machine to ensure precision and quality. Furthermore, the integration of IoT for filter monitoring is gaining traction, allowing for real-time performance tracking, predictive maintenance, and optimized replacement schedules, leading to greater efficiency and cost savings.

The paradigm shift towards electric vehicles (EVs) and hybrid vehicles presents unique filtration challenges and opportunities. Specialized filtration solutions are now crucial for battery cooling systems and enhanced HVAC in EVs, which operate differently from traditional internal combustion engine (ICE) vehicles. Companies are investing in R&D to develop filters tailored for these new demands, ensuring optimal thermal management and cabin air quality in the electrified automotive ecosystem. The ability to quickly adapt and manufacture these new types of filters, perhaps even leveraging technologies seen in industrial applications like a pure water treatment filter machine or a compress air filter making machine, showcases the versatility of modern filter manufacturers.

Market Data Insights:

The global automotive filter market is projected for steady growth, particularly in the aftermarket segment and emerging economies. Key drivers include:

- Increased global vehicle parc.

- Stringent emission regulations pushing for better engine and exhaust filtration.

- A heightened focus on occupant health, driving demand for superior cabin air quality.

While electrification poses long-term shifts, traditional ICE vehicle filters will remain significant for decades, complemented by new filtration requirements for EVs. This dual demand underscores a robust and evolving market.

Emerging focus areas for the industry include sustainable and high-efficiency filtration solutions, the integration of smart manufacturing principles into supply chains, ensuring global trade resilience amidst geopolitical shifts, and a proactive adaptation to the evolving EV market's distinct filtration needs. Manufacturers are also exploring diversified product lines, drawing upon expertise gained from advanced machines like the pp spun filter cartridge making machine or even industrial solutions like a reverse osmosis water filter machine, showcasing a broader capability in filtration technology.

Profiles of Leading Companies Driving Innovation

The 135th Canton Fair shone a spotlight on numerous industry leaders, both established giants and agile innovators from China. These companies are not just producing auto parts; they are shaping the future of filtration.

Hebei Filter Man Automotive Parts Trading Co., Ltd

As a prominent exhibitor, Hebei Filter Man Automotive Parts Trading Co., Ltd exemplifies specialized expertise in automotive filtration products. Their very name and dedicated online presence (like mfiltersolution.com) underscore a focused approach to providing high-quality solutions for buyers. Strategically located in Hebei, a key industrial region in China, the company benefits from robust supply chain access, enabling efficient sourcing and timely delivery. As a trading company, Hebei Filter Man offers numerous advantages to international buyers, including competitive pricing, broad product sourcing capabilities across various manufacturers (potentially including those using advanced technology like a compress air filter making machine), and established international logistics expertise. They are poised to be a pivotal partner for businesses seeking reliable and diverse automotive filtration components. Their comprehensive offerings suggest a readiness to cater to a wide spectrum of automotive and industrial filtration needs, hinting at the versatility in their supply chain, which might even involve technologies for a sunflower seeds oil filter machine or a screw press sludge dewatering machine, demonstrating a profound understanding of filtration across sectors.

Beyond regional specialists, the global filtration market is also shaped by established multinational corporations and a network of other capable manufacturers and traders.

- Mann+Hummel: A global leader known for its extensive range of filtration solutions across various applications.

- Mahle GmbH: A prominent supplier to the automotive industry, offering comprehensive filtration systems for engines and cabins.

- Donaldson Company, Inc.: Renowned for its diverse industrial and engine filtration products, pushing the boundaries of filter technology.

- Sogefi S.p.A.: A key player in the automotive original equipment and aftermarket, providing oil, air, fuel, and cabin filters.

- Bosch: A technology and service giant, offering a wide array of automotive components, including high-quality filters.

- Fram Filtration: A household name in automotive filtration, particularly strong in the aftermarket segment.

- Numerous other regional automotive parts traders and manufacturers, many of whom utilize advanced production lines, including specialized air filter air filter making machine setups, contribute significantly to the dynamic and competitive landscape, offering a breadth of options for global buyers.

Market Outlook & Opportunities: Charting Future Growth

The market outlook for auto parts and filter elements remains robust, fueled by consistent vehicle production, an expanding global car parc, and increasingly stringent regulatory demands. Upcoming trends indicate a strong buyer demand for products that offer not only superior performance and reliability but also enhanced sustainability features. Manufacturers are gearing up to meet these demands by investing heavily in R&D and advanced manufacturing processes.

Significant opportunities lie in the realm of automation and smart manufacturing. The adoption of advanced robotics and IoT in production facilities, facilitated by machines like the professional air filter making machine and efficient paper folding machine for air filter, leads to higher precision, reduced waste, and increased output. This efficiency is crucial for meeting global demand. Furthermore, the push for sustainability is opening doors for innovations in biodegradable filter media, recyclable components, and energy-efficient manufacturing processes, extending beyond just automotive to broader filtration challenges, potentially even leveraging lessons learned from developing a reverse osmosis water filter machine for industrial purposes. The shift towards circular economy models will increasingly influence product design and material selection.

The emerging needs of the EV sector also present a fertile ground for growth. As EV adoption accelerates, the demand for specialized filtration – from battery cooling systems to advanced cabin air purification – will surge. Companies that can swiftly adapt their product lines and manufacturing capabilities, perhaps by diversifying their filter making machinery to include specialized pp spun filter cartridge making machine variants for unique EV requirements, will secure a competitive edge.

Buyer/Business Takeaways: Strategic Moves in a Dynamic Market

For B2B decision-makers, investing in auto parts and filter elements, particularly those sourced from China, makes sound strategic and economic sense. Chinese manufacturers and trading companies offer a compelling combination of quality, cost-effectiveness, and rapid innovation, backed by sophisticated production capabilities, including robust car air filter making machine facilities.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Research potential partners extensively, checking certifications, production capabilities (e.g., if they utilize a specific pure water treatment filter machine for quality control, or an advanced pp spun filter cartridge making machine for diverse product lines), and track records.

- Establish Clear Communication Channels: Effective and transparent communication is crucial for successful long-term partnerships, especially across different time zones and cultures.

- Understand the Supply Chain: Gain insights into their manufacturing process, quality control, and logistics to ensure reliability and consistency.

- Focus on Long-Term Relationships: Building trust and fostering sustained collaboration yields the best outcomes, including tailored solutions and preferential terms.

Future-Proof Strategies:

- Diversify Your Portfolio: Explore both traditional ICE and emerging EV filtration needs to cater to a broader market.

- Invest in R&D: Stay ahead of the curve by supporting innovation in sustainable materials, advanced filtration media, and smart technologies.

- Embrace New Technologies: Integrate IoT for predictive maintenance, explore AI-driven supply chain optimization, and adopt advanced manufacturing techniques, possibly even drawing inspiration from diverse filtration technologies such as those used in a screw press sludge dewatering machine or a sunflower seeds oil filter machine for material or process innovation.

Conclusion: The Canton Fair's Enduring Impact

The 135th Canton Fair underscored its enduring importance as a global nexus for trade, significantly shaping the future of the auto parts and filter element market. It showcased China's pivotal role as a hub for both manufacturing prowess and innovative trading solutions, where companies are not only equipped with cutting-edge production machinery but also possess the logistical expertise to serve international markets effectively. The event reaffirmed that collaboration, technological advancement, and a keen eye on sustainability will be the cornerstones of success in this dynamic industry.

For businesses looking to navigate the complexities and capitalize on the opportunities within automotive filtration, engaging with leading Chinese suppliers is a strategic imperative. We invite you to explore the extensive capabilities and diverse product offerings of Hebei Filter Man Automotive Parts Trading Co., Ltd.

Visit our product page to learn more about our comprehensive filtration solutions and capabilities!

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025