Aug . 02, 2024 14:36 Back to list

Exploring Competitive Pricing for 100% PP Materials Filters in the Market Today

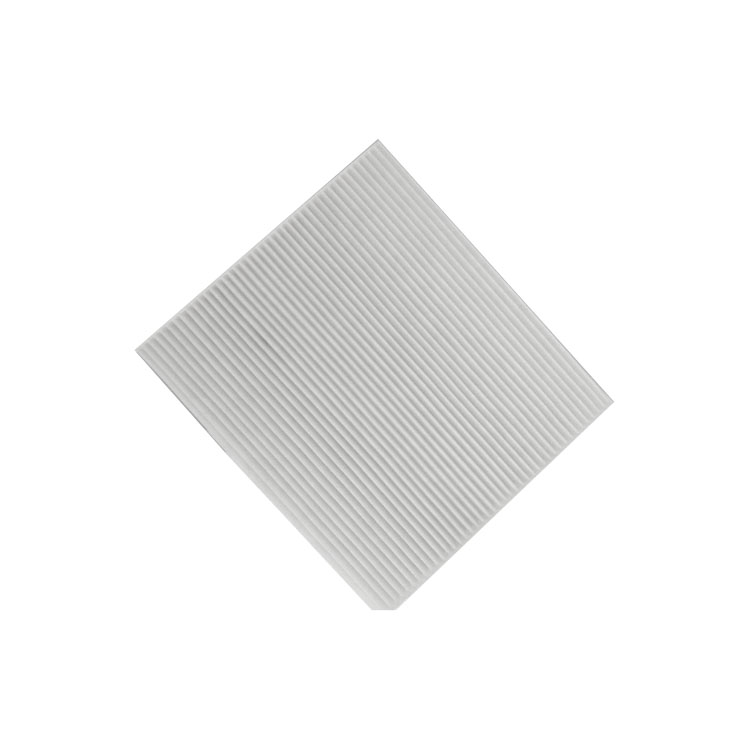

Understanding 100% PP Materials and Their Importance in Filtration

In today's world, the demand for high-quality filtration solutions has risen sharply across various industries, ranging from manufacturing to water treatment. One of the key materials gaining popularity for these filtration applications is polypropylene (PP), particularly in its 100% form. This article explores the significance of 100% PP materials in filtration systems, their benefits, and some practical applications.

What are 100% PP Materials?

100% PP materials are derived from polypropylene, a thermoplastic polymer known for its versatility, chemical resistance, and lightweight properties. In the context of filtration, PP materials are used to create filter media that are effective in removing impurities from liquids and gases. Unlike composite filters that may contain a blend of different materials, filters made from 100% PP ensure a consistent performance and higher durability.

Benefits of 100% PP Filters

1. Chemical Resistance One of the standout advantages of using 100% PP materials in filtration is their excellent resistance to a wide range of chemicals. This makes them suitable for various industrial applications, including petrochemicals, food processing, and wastewater treatment, where exposure to harsh substances is common.

2. Durability Filters made from 100% PP are known for their resistance to wear and tear. This inherent toughness allows them to maintain structural integrity under pressure, making them suitable for high-flow applications.

3. Lightweight and Easy to Handle PP materials are lightweight, facilitating easy installation and maintenance of filtration systems. This is particularly advantageous in large-scale operations where manual handling can be cumbersome.

100%pp materials filter quotes

4. Cost-Effectiveness While the initial investment in high-quality 100% PP filters may be slightly higher than other materials, their long lifespan and low maintenance requirements often result in reduced operational costs over time.

5. Versatility 100% PP materials can be engineered to meet various filtration requirements, allowing manufacturers to produce filters with specific pore sizes and retention rates. This adaptability makes them suitable for a diverse range of applications, from air and water filtration to specialized industrial processes.

Applications of 100% PP Materials in Filtration

The versatility of 100% PP filters has led to their utilization in numerous fields. In water treatment facilities, they are employed to eliminate sediments and contaminants, ensuring safe and clean drinking water. The food and beverage industry uses these filters to maintain product quality by removing particles that could affect the taste or safety of the products.

In pharmaceutical and biotechnology sectors, 100% PP filters are critical for ensuring the purity of products by filtration of fine particles and microbes. Additionally, in air filtration systems, these materials play a vital role in enhancing indoor air quality by trapping allergens, dust, and other airborne contaminants.

Conclusion

As industries continue to prioritize cleanliness, efficiency, and safety, the importance of high-quality filtration systems cannot be overstated. 100% PP materials offer an effective and durable solution for various filtration needs. Their unique combination of chemical resistance, durability, light weight, and versatility makes them a preferred choice for manufacturers looking to optimize their filtration processes. As technology evolves, we can anticipate even broader applications and innovative designs utilizing 100% PP materials, ensuring a cleaner and healthier environment for all.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025