Jul . 27, 2024 05:59 Back to list

Exploring Quotes on Fire Resistance and the Importance of Specialized Filter Paper in Safety Applications

Fire Resistance Filter Paper An Essential for Safety and Efficiency

In today's world, safety and efficiency are paramount in various industries, particularly those dealing with high temperatures or flammable materials. One crucial element in achieving these standards is the use of fire resistance filter paper. This specialized filter paper serves as a barrier against fire-related hazards while maintaining high levels of performance in filtration processes.

Understanding Fire Resistance Filter Paper

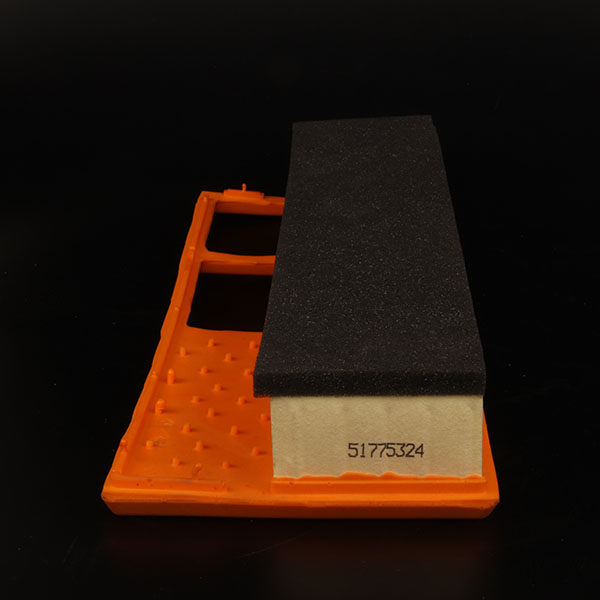

Fire resistance filter paper is designed to withstand high temperatures and resist ignition. It is commonly used in applications where the risk of fire is significant, such as in laboratories, manufacturing plants, and automotive industries. The material is treated with fire retardant agents, enhancing its ability to resist flames and slow down the spread of fire. This property is vital for protecting equipment, personnel, and valuable materials from fire damage.

Advantages of Using Fire Resistance Filter Paper

One of the primary benefits of fire resistance filter paper is its ability to enhance safety. In environments where combustible materials are present, traditional filter papers can pose a serious risk if they come into contact with heat sources. Fire resistance filter paper, on the other hand, provides an extra layer of protection, allowing organizations to operate more confidently in high-risk conditions.

Additionally, this type of filter paper often exhibits superior filtration efficiency. It is engineered to capture fine particles, dust, and other contaminants without compromising the airflow. As a result, businesses can maintain cleaner environments, improve the quality of their products, and reduce the risk of contamination. This aspect is particularly important in industries such as food processing and pharmaceuticals, where cleanliness is crucial.

fire resistance filter paper quotes

Applications in Various Industries

Fire resistance filter paper is incredibly versatile and finds applications across multiple sectors. In the automotive industry, it is used in manufacturing filters for engines and exhaust systems, where high temperatures are a concern. The aerospace sector also employs this material to satisfy stringent safety regulations, ensuring that all components can withstand extreme conditions.

In laboratory settings, fire resistance filter paper is utilized for testing and filtering reactive substances. The ability to resist ignition makes it an essential component for researchers handling flammable chemicals. Moreover, it is employed in industrial processes where dust and particulate matter must be filtered out without risking fire hazards.

Cost-effectiveness and Environmental Considerations

While fire resistance filter paper may have a higher initial cost than standard filter solutions, the long-term benefits often outweigh the expenses. By reducing the risk of fire-related incidents, organizations can save significantly on potential damages, insurance premiums, and downtime. Additionally, fire resistance filter papers are often designed with environmentally friendly materials, making them a sustainable choice for companies looking to minimize their ecological footprint.

Conclusion

As industries continue to evolve, the need for innovative solutions to ensure safety and efficiency becomes increasingly important. Fire resistance filter paper stands out as a critical component in achieving these goals. By integrating this advanced material into various processes, organizations can mitigate risks, enhance performance, and protect both personnel and assets. In a world where safety cannot be compromised, fire resistance filter paper proves to be a reliable ally, ensuring that businesses can operate smoothly and securely.

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025