Aug . 15, 2024 01:01 Back to list

Exploring the Benefits and Applications of OEM Technology in 0.3-Micron Filtration Systems

The Significance of OEM 0.3 Micron Technology in Modern Applications

In the rapidly evolving world of technology, Original Equipment Manufacturer (OEM) products are becoming increasingly important in various industries. One of the critical aspects of OEM technology is the ability to produce components with extremely precise specifications. In this context, 0.3 micron technology stands out due to its applications in various fields, including electronics, medical devices, and environmental monitoring.

The Significance of OEM 0.3 Micron Technology in Modern Applications

In the electronics industry, 0.3 micron technology plays a vital role in the manufacturing of semiconductors, integrated circuits, and microelectromechanical systems (MEMS). As consumer demand for smaller, faster, and more efficient devices grows, manufacturers strive to achieve increasingly small feature sizes in their products. The capability of producing semiconductor components at the 0.3-micron level enables the development of high-performance chips that meet the demands of modern computing, telecommunications, and consumer electronics.

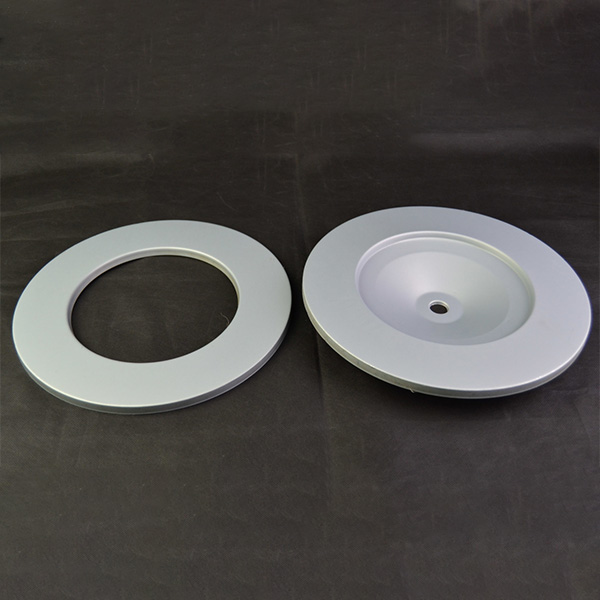

oem 0.3 micron

Moreover, in the medical field, 0.3 micron technology has significant implications for the development of diagnostic tools and therapeutic devices. For instance, filtration systems used in medical devices must be designed to trap particles, including bacteria and viruses, to ensure patient safety. Filters with a pore size of 0.3 microns can effectively capture airborne pathogens, making them essential for devices such as ventilators and anesthesia machines. In this way, the adoption of OEM components that meet this specification can directly influence patient outcomes and enhance the overall standards of healthcare technology.

Outside of traditional manufacturing domains, 0.3 micron technology is also critical in environmental monitoring. With increasing awareness of air quality and its impact on health, the ability to measure particulate matter (PM) at such a fine scale is vital. Devices equipped with sensors that can detect particles of 0.3 microns or smaller can provide real-time data on air pollution levels, contributing to better public health policies and environmental protections. This technology is particularly relevant in urban areas where particulate pollution poses significant health risks.

Furthermore, the collaboration between OEM manufacturers and research institutions is fostering innovation in this field. By leveraging advanced materials and innovative manufacturing processes, OEMs can create products that not only meet 0.3 micron specifications but also incorporate additional functionalities, such as antimicrobial properties or enhanced filtration capabilities. This ongoing research continues to push the boundaries of what is possible with micro-scale technology.

In conclusion, the significance of OEM 0.3 micron technology cannot be overstated. Its applications span multiple industries, including electronics, healthcare, and environmental science, each playing a critical role in enhancing efficiency, safety, and performance. As demand for precision components continues to rise, the ability of OEM manufacturers to deliver products at this scale will remain pivotal. Looking forward, advancements in 0.3 micron technology will undoubtedly lead to further innovations, benefiting society as a whole and paving the way for smarter, healthier, and more sustainable technologies.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

Premium Active Carbon Air Filter for Purifiers - Odor & VOC Removal

NewsAug.15,2025

-

PLAB-6 A B Filter Gluing Machine - Hebei Filter Man

NewsAug.14,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd.|Adjustable Speed&Step Motor Control

NewsAug.14,2025