Aug . 14, 2024 08:11 Back to list

Export Options for High-Quality Fuel Filters Designed for Caterpillar Truck Engines

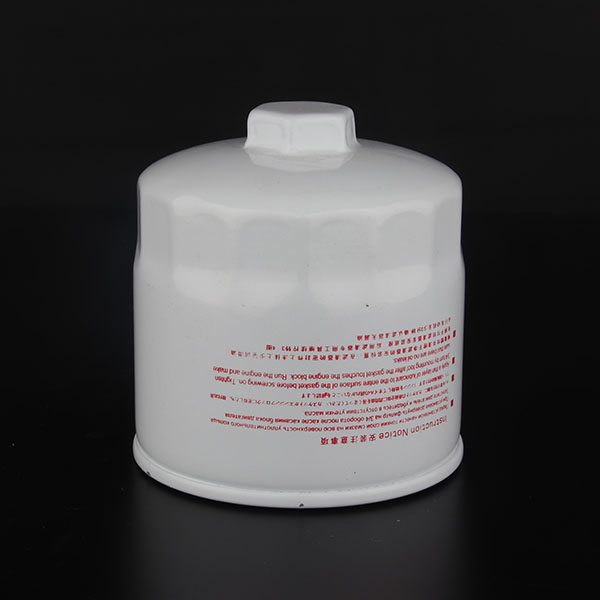

Fuel Filter for Caterpillar Truck Engine A Vital Component for Optimal Performance

In the world of heavy machinery and trucking, the importance of maintaining engine performance cannot be overstated. For Caterpillar truck engines, a critical component often overlooked is the fuel filter. This device plays a pivotal role in ensuring that the engine runs smoothly and efficiently. With the growing demand for Caterpillar trucks and their components, there is also an increasing market for fuel filter exporters who can provide high-quality filtration solutions.

Understanding Fuel Filters

Fuel filters are designed to remove impurities from the fuel before it enters the engine. Contaminants such as dirt, rust, and other particulates can significantly affect an engine's performance. If these impurities are allowed to enter the fuel system, they can lead to clogged injectors, reduced fuel efficiency, and even catastrophic engine failure. By regularly replacing fuel filters, vehicle operators can protect their investment and extend the lifespan of their engines.

The Role of Fuel Filters in Caterpillar Engines

Caterpillar engines are known for their durability and exceptional performance in demanding conditions. However, even the most robust engine can suffer from the effects of poor fuel quality. Fuel filters play a vital role in ensuring that only clean fuel reaches the engine. For Caterpillar truck engines, which are often used in heavy-duty applications, the importance of reliable fuel filtration cannot be overstated. A quality fuel filter helps maintain engine efficiency, reduces maintenance costs, and ensures compliance with emissions regulations.

Exporting Fuel Filters for Caterpillar Trucks

fuel filter for caterpillar truck engine exporters

As the demand for Caterpillar trucks grows globally, so does the need for quality fuel filters. Exporters specializing in fuel filters for Caterpillar engines must focus on several key factors to succeed in this competitive market. First and foremost, product quality is paramount. Filters must meet the rigorous standards set by manufacturers to ensure they effectively remove contaminants without restricting fuel flow.

Additionally, exporters should prioritize building relationships with trusted manufacturers. Many reputable filter manufacturers have established their credibility in the market by producing filters that give proven performance over time. Collaborating with these manufacturers can help exporters ensure they are providing their clients with the best possible products.

Meeting Compliance and Quality Standards

In the export business, compliance with international standards is crucial. Fuel filter exporters must ensure that their products adhere to the relevant regulations in the countries they serve. This includes understanding specific requirements regarding environmental standards and fuel quality.

Moreover, after-sales support is an often-underestimated aspect of exporting. Providing comprehensive customer service, including technical support and product warranties, can help build a loyal customer base. When clients trust that they can rely on their suppliers for quality and support, they are more likely to return for repeat business.

Conclusion

In conclusion, the fuel filter is a vital component of Caterpillar truck engines that warrants careful consideration, both in terms of maintenance and quality sourcing. Exporters of fuel filters play a significant role in ensuring truck owners can maintain optimal engine performance. By focusing on quality, compliance, and customer service, exporters can establish a strong presence in the market and meet the rising demand for Caterpillar truck components. As the trucking industry continues to evolve, the importance of reliable fuel filtration will only become more pronounced, making it a lucrative field for dedicated exporters.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025