Aug . 06, 2024 14:39 Back to list

Exporter of Pore Size Measurement Instruments for High-Quality Filter Paper Solutions

The Importance of Pore Size Measurement in Filter Paper Production

In the world of filtration, the quality and efficiency of filter paper play a critical role in various applications ranging from laboratory research to industrial processes. One essential aspect that determines the performance of filter paper is its pore size. Accurate measurement of pore size is vital for ensuring that filter paper meets the required specifications for its intended use, and this is where advanced measuring instruments come into play.

Filter paper is often characterized by its ability to separate particles from liquids or gases. This efficiency is largely dictated by the pore size, which affects flow rates, retention capabilities, and overall filtration performance. A well-defined pore structure ensures that the filter paper can effectively trap contaminants while allowing the desired fluid to pass through. Therefore, it is crucial for manufacturers and researchers to have reliable instruments that can measure the pore size with precision.

Pore size measuring instruments come in various forms, each designed to cater to specific needs in the filtration industry. These instruments vary from simple manual devices to sophisticated automated systems that provide detailed analyses of pore size distribution. One of the most commonly used methods is the capillary flow porometer, which measures the pore sizes based on the flow of liquid through the filter medium. This method not only provides the average pore size but also gives a detailed distribution of pore sizes, which is essential for both quality control and research purposes.

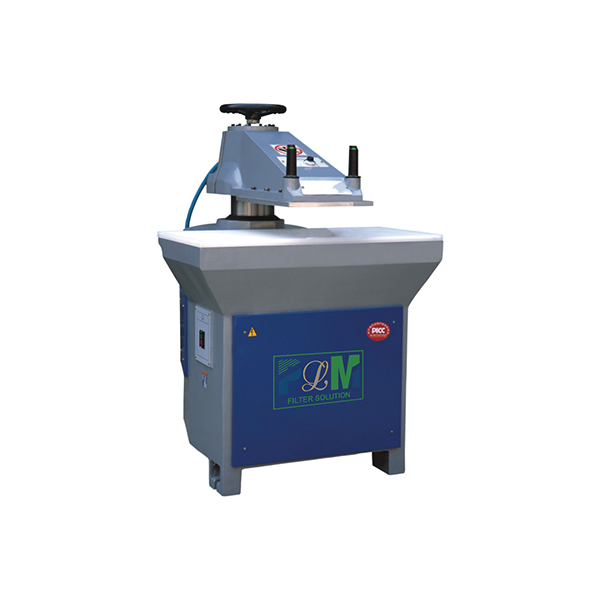

plkj-20 filter paper pore size measuring instrument exporter

The market for filter paper and its measuring instruments has seen significant growth, largely driven by the increasing demand for high-performance filters in sectors such as pharmaceuticals, food and beverage, and environmental testing. Exporters of filter paper must ensure that their products meet international standards, which often requires comprehensive testing and validation. This has led to an increase in the demand for pore size measuring instruments that are accurate, efficient, and easy to use.

As an exporter of filter paper and related measuring instruments, it is crucial to stay ahead of the competition by leveraging the latest technology in pore size measurement. Advanced devices not only deliver accurate measurements but also come equipped with software that can analyze data and generate reports, thus facilitating better decision-making in the manufacturing process. Additionally, these instruments can help in the R&D phase, allowing for the design of filters with tailored properties for specific applications.

In conclusion, the measurement of pore size in filter paper is an indispensable aspect of the filtration industry. It ensures product quality and performance, helping to meet the diverse needs of customers across various sectors. For exporters, investing in high-quality pore size measuring instruments not only enhances product credibility but also contributes to the overall efficiency of the production process. As industries continue to evolve and demand more sophisticated filtration solutions, the relevance of accurate pore size measurement will only grow, reinforcing the importance of this crucial aspect of filter paper production.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025