Oct . 31, 2024 12:48 Back to list

Exploring Filter Mould Products and Their Applications in Various Industries

The Importance of Filter Mould Products in Modern Industry

Filter mould products play a crucial role in various industries, serving vital functions in the filtration process. With advancements in technology and increasing environmental concerns, the demand for efficient and reliable filter moulds has never been higher. These products, designed for durability and efficiency, ensure that industries can meet safety and regulatory standards while also enhancing operational effectiveness.

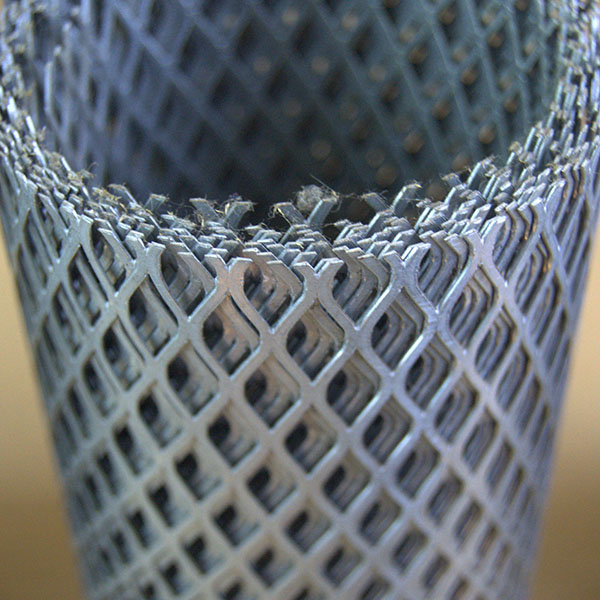

Filter mould products are primarily used in applications such as air, liquid, and gas filtration. They are designed to capture impurities, particulate matter, and other contaminants that can pose significant risks to both health and equipment. The production of these moulds involves intricate processes that require precision engineering and high-quality materials. Typically made from polymers or metals, filter moulds are designed to withstand harsh conditions, including high temperatures, corrosive materials, and high-pressure environments.

One of the key advantages of filter mould products is their customization potential. Manufacturers are now capable of producing tailored solutions that meet specific industry needs. Whether it's for automotive, pharmaceuticals, food and beverage, or industrial applications, custom filter moulds can be designed to optimize performance. This level of specialization not only improves the efficiency of filtration systems but also extends the lifespan of the components involved.

filter mould products

Moreover, the significance of filter moulds is underscored by increasing regulatory pressures. Many industries face stringent regulations concerning emissions and the quality of products. For instance, in the automotive industry, filter mould products help in reducing harmful emissions, thus complying with environmental standards. In the healthcare sector, they ensure that air and liquid filtration meet safety requirements, thereby protecting both patients and healthcare workers.

The manufacturing process of filter mould products has evolved considerably. Techniques like injection moulding and 3D printing are being employed to create intricate designs that enhance filtration efficiency. These methods not only minimize waste but also reduce production time, making it easier for manufacturers to respond to market demands swiftly. Additionally, the adoption of smart technologies in production enables real-time monitoring and quality control, further ensuring that these products meet high-performance standards.

In summary, filter mould products are an indispensable part of modern industrial operations. Their ability to effectively filter out contaminants not only protects the environment but also enhances the safety and reliability of various processes. As industries continue to face challenges related to sustainability and compliance, the evolution and refinement of filter mould technology will be essential. Investing in high-quality filtration solutions will not only meet current regulatory requirements but will also pave the way for a cleaner and safer future. With ongoing advancements, the role of filter mould products will undoubtedly expand, playing a vital part in supporting a sustainable world.

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025