Aug . 29, 2024 08:24 Back to list

Full-Auto Knife Paper Pleating Production Line - Efficient & Reliable Solutions

Full-Auto Knife Paper Pleating Production Line Revolutionizing the Industry

The advent of technology has significantly transformed various industries, and the paper processing sector is no exception. One of the remarkable innovations in this field is the full-auto knife paper pleating production line. This automated system not only enhances efficiency but also ensures precision in the production of pleated paper products, catering to diverse applications, from packaging to decorative purposes.

What is Knife Paper Pleating?

Knife paper pleating is a process that involves creating folds or pleats in paper using sharp cutting mechanisms, known as knives. This technique is widely used in the production of disposable tableware, decorative items, and various packaging solutions. The manual pleating process can be labor-intensive and time-consuming, often leading to inconsistencies in quality and output. The introduction of an automated production line addresses these challenges by utilizing advanced machinery to streamline the entire process.

Advantages of Full-Auto Production Lines

1. Increased Efficiency The full-auto knife paper pleating production line significantly increases the speed of production. Machines can operate continuously, reducing the time needed to complete large orders. This not only meets high market demands but also improves overall productivity.

2. Consistent Quality Automation ensures that every pleat is uniform and meets the specified standards. The precision of the knives and the control mechanisms minimize human error, ensuring that the final products are of high quality and consistent in appearance.

full-auto knife paper pleating production line products

3. Cost-Effectiveness While the initial investment in such automated lines may be substantial, the long-term savings are significant. Reduced labor costs, lower waste due to precision, and increased production rates all contribute to a more cost-effective operation.

4. Flexibility in Production Modern full-auto knife paper pleating production lines offer flexibility that allows manufacturers to easily switch between different paper types and pleating patterns. This adaptability enables businesses to cater to various customer requests without extensive downtime.

5. Enhanced Safety Automation reduces the need for manual handling of sharp knives, which can be hazardous. With automated systems, the risk of injuries is minimized, creating a safer working environment.

Applications of Pleated Paper Products

Pleated paper products have a wide range of applications. They are commonly used in the food service industry for disposable plates, cups, and trays, providing an aesthetic enhancement while maintaining functionality. Additionally, pleated paper is utilized in arts and crafts, packaging materials, and even decorative purposes, showcasing its versatility.

Conclusion

The full-auto knife paper pleating production line represents a significant advancement in the paper processing industry. By combining speed, precision, and safety, this technology is transforming how paper products are manufactured. As businesses seek to improve efficiency and quality, investing in such automated systems will undoubtedly lead to a more prosperous future. The transition to automation not only benefits manufacturers but also enhances the quality of products available to consumers, proving that innovation is indeed the cornerstone of progress in any industry.

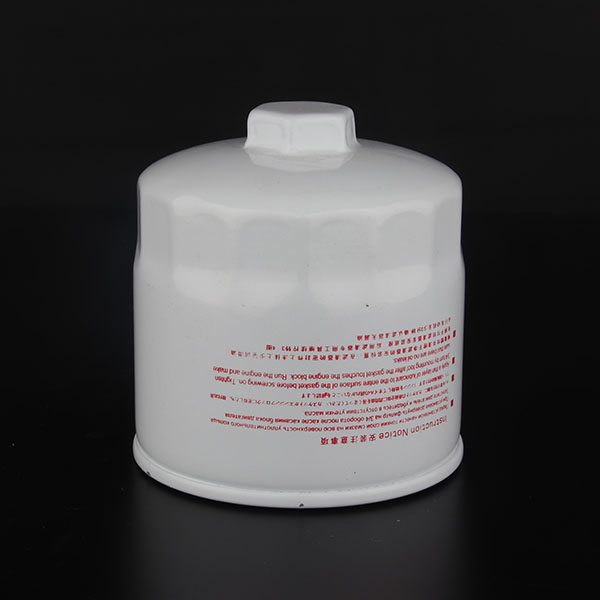

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025