Aug . 06, 2024 01:52 Back to list

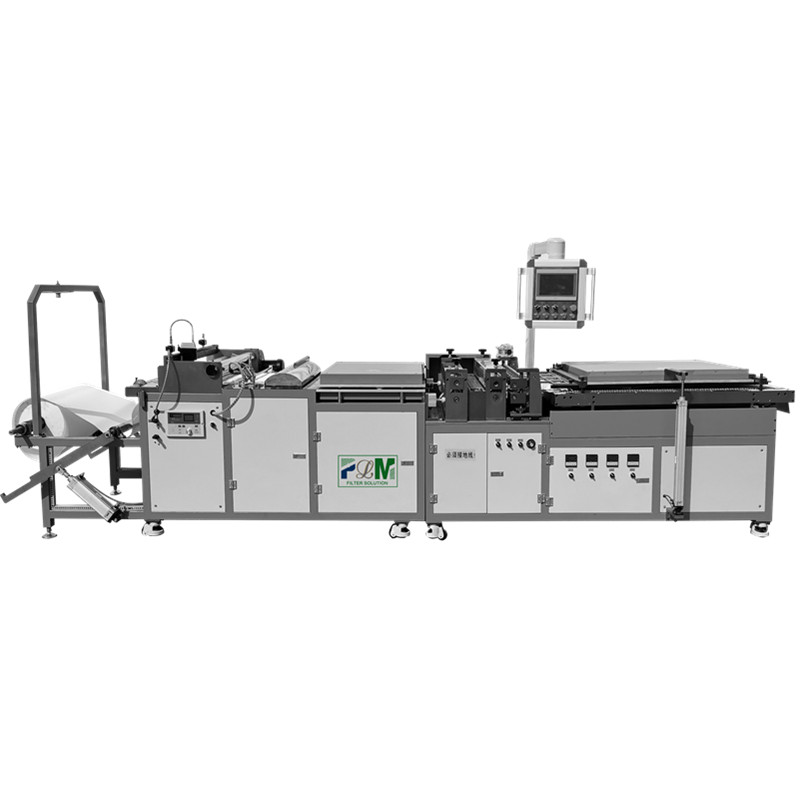

High-Efficiency Horizontal Gluing Machine PLWS-950 for Exporting High-Quality Adhesive Solutions

Exploring the Prowess of the PLWS-950 HDAF Horizontal Gluing Machine Exporters

In the competitive landscape of manufacturing, the choice of machinery can drastically influence both productivity and product quality. Among these critical machines, the PLWS-950 HDAF Horizontal Gluing Machine stands out, particularly for exporters aiming to enhance their production capabilities. This article explores the characteristics, benefits, and market potential of the PLWS-950, and shed light on the role of exporters in promoting this advanced machinery.

Understanding the PLWS-950 HDAF Horizontal Gluing Machine

The PLWS-950 HDAF is designed for versatility and efficiency, engineered to cater specifically to industries that require precise and robust gluing solutions. This machine operates with a horizontal structure, which allows it to handle various materials such as cardboard, paper, and wood efficiently. One of its significant features is its high-speed operation, which can significantly reduce production times while maintaining high accuracy in glue application.

Equipped with advanced technology, the PLWS-950 ensures consistent glue distribution, minimizing waste and maximizing adhesion strength. This trait is particularly crucial in industries such as packaging and furniture production, where the integrity of the final product heavily relies on the quality of the adhesion. The machine’s user-friendly interface and automated features further enhance its appeal, enabling operators to work with minimal technical challenges.

Benefits of the PLWS-950 for Exporters

Exporters of the PLWS-950 HDAF not only benefit from a robust product but also from the growing demand for efficient manufacturing solutions across various sectors. The machine's ability to integrate seamlessly into existing production lines makes it a valuable asset for manufacturers looking to upgrade their capabilities.

plws-950 hdaf horizontal gluing machine exporters

One of the key advantages of the PLWS-950 is its adaptability. It can be customized to meet specific client needs, whether they are in the printing, packaging, or woodworking industries. This flexibility allows exporters to tap into diverse markets and address specific challenges faced by clients, enhancing customer satisfaction and fostering long-term relationships.

Additionally, the global push towards sustainability has spurred interest in machines that optimize resource use. The PLWS-950 achieves this by reducing glue consumption through its precision application system, aligning with modern environmental standards. This aspect not only appeals to eco-conscious companies but also positions exporters as forward-thinking partners in sustainability.

Market Potential and Future Trends

With the increasing globalization of markets, the demand for high-quality machinery like the PLWS-950 HDAF is poised to rise. Exporters can leverage this trend by highlighting the machine's advantages in their marketing strategies. Demonstrations of the machine's capabilities at manufacturing trade shows and exhibitions can also attract potential buyers by showcasing its innovation and efficiency.

As industries continue to evolve, the integration of digital technologies and smart manufacturing processes is becoming paramount. Exporters of the PLWS-950 should stay ahead by adopting advanced technologies such as IoT for real-time monitoring and AI for predictive maintenance. This will not only enhance the appeal of the machine but also ensure that it meets the future needs of manufacturers globally.

Conclusion

The PLWS-950 HDAF Horizontal Gluing Machine represents a significant advancement in gluing technology, offering numerous benefits for manufacturers and exporters alike. As industries navigate the complexities of modern production, machines that combine efficiency, adaptability, and sustainability will play a crucial role. Embracing this opportunity, exporters can position themselves as leaders in the global market, driving innovation and setting new standards in manufacturing excellence. The future looks promising for those who recognize and capitalize on the potential of the PLWS-950 and similar advanced machinery.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025