Aug . 06, 2024 07:00 Back to list

High-Performance Cutting Machine for Toyota Filter Element Pack Production and Assembly Solutions

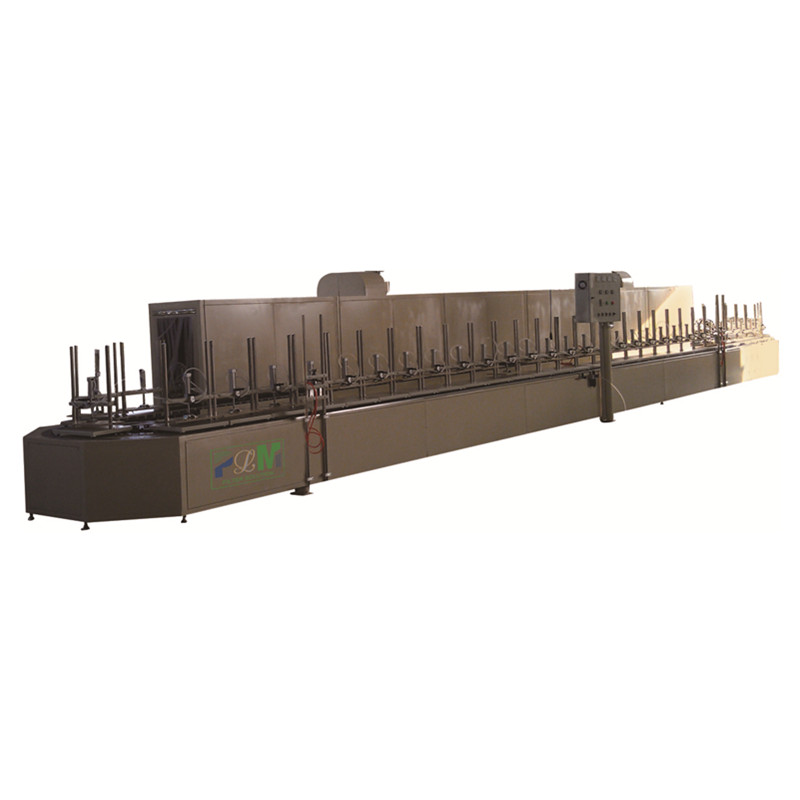

Reliable Solutions for Efficient Filter Element Production The PLQ-CQ-1% Toyota Filter Element Pack Cutting Machine

In today’s manufacturing landscape, particularly in the automotive sector, precision and efficiency are paramount. For companies focusing on filter manufacturing, cutting machines that can enhance productivity without compromising quality are vital. The PLQ-CQ-1% Toyota Filter Element Pack Cutting Machine provides an essential solution for manufacturers aiming to streamline their production processes.

Overview of the PLQ-CQ-1% Cutting Machine

The PLQ-CQ-1% Cutting Machine has been engineered with advanced technology that aligns with Toyota's legendary commitment to quality and performance. Designed specifically for cutting filter elements, this machine is capable of handling a variety of materials used in filter production, ensuring versatility in application. Whether it’s for air filters, oil filters, or fuel filters, the PLQ-CQ-1% stands out as a reliable choice for manufacturers.

Efficiency and Precision

One of the primary advantages of the PLQ-CQ-1% Cutting Machine is its efficiency. With high-speed cutting capabilities, it minimizes downtime and maximizes production output. This is particularly crucial as the demand for automotive filters continues to rise, driven by growing vehicle production rates and stricter environmental regulations. Manufacturers using the PLQ-CQ-1% can expect a significant increase in their output without the risk of quality compromise, thanks to its state-of-the-art cutting technology that ensures precise dimensions and clean edges.

The precision of this cutting machine is backed by computer numerical control (CNC) systems that guarantee accuracy in cutting patterns. Operators can program the machine to produce filters with specific dimensions, which is essential in a market where customization is increasingly important. This level of precision limits material waste and reduces the need for rework, thereby contributing to significant cost savings over time.

plcq-1 toyota filter element pack cutting machine quotes

User-Friendly Design

Beyond its technical capabilities, the PLQ-CQ-1% is designed with the user in mind. The intuitive interface allows operators to quickly learn and master the machine's functionality, reducing the training time for new staff. Moreover, regular maintenance is simplified, which helps in minimizing machine downtime and extending the equipment's lifespan. Manufacturers can focus on their core operations without worrying about complicated machinery, which can often lead to increased operational costs.

Sustainable Manufacturing Practices

As sustainability becomes a focal point for manufacturers globally, the PLQ-CQ-1% Toyota Filter Element Cutting Machine supports eco-friendly practices. Its efficient cutting process not only conserves materials but also integrates features that help minimize waste production. Additionally, its ability to create filters that comply with stringent environmental standards makes it a valuable asset for companies looking to enhance their sustainability credentials.

Conclusion

The PLQ-CQ-1% Toyota Filter Element Pack Cutting Machine is a transformative piece of equipment for manufacturers in the filter production sector. With its blend of efficiency, precision, and user-friendly design, it serves as a testament to Toyota's commitment to innovation and quality in manufacturing. As the automotive industry continues to evolve, investing in advanced machinery like the PLQ-CQ-1% is crucial for companies aiming to stay competitive and meet the growing demands of the market. Adopting such technology not only boosts productivity but also significantly contributes to sustainable operational practices.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025