Sep . 03, 2024 16:30 Back to list

high quality plgt-600n full-auto rotary eco filter paper pleating production line

High-Quality PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line

In today's ever-evolving manufacturing landscape, the demand for efficient, sustainable, and high-quality production processes has never been more prominent. One of the key innovations in this domain is the PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line. This advanced system is designed specifically for the production of filter paper, catering to various industrial applications, from automotive to air and liquid filtration.

Overview of the PLGT-600N

The PLGT-600N represents a significant leap forward in filter paper manufacturing technology. With its fully automated operation, this production line minimizes human intervention, reducing the risk of errors and enhancing production efficiency. The rotary design allows for continuous operation, meaning that large volumes of filter paper can be produced without interruption, thus meeting the growing market demand.

One of the standout features of the PLGT-600N is its eco-friendly design. It is equipped with energy-efficient mechanisms and utilizes sustainable materials, aligning with global efforts to reduce environmental impact and promote greener manufacturing practices. This commitment to sustainability not only enhances the marketability of the end products but also adheres to increasing regulations regarding environmental responsibility.

Key Features and Benefits

1. High Precision and Quality The PLGT-600N is engineered for precision. It employs advanced technology to ensure that filter paper pleats are uniformly sized and accurately positioned, which is critical for optimal filtering performance in practical applications.

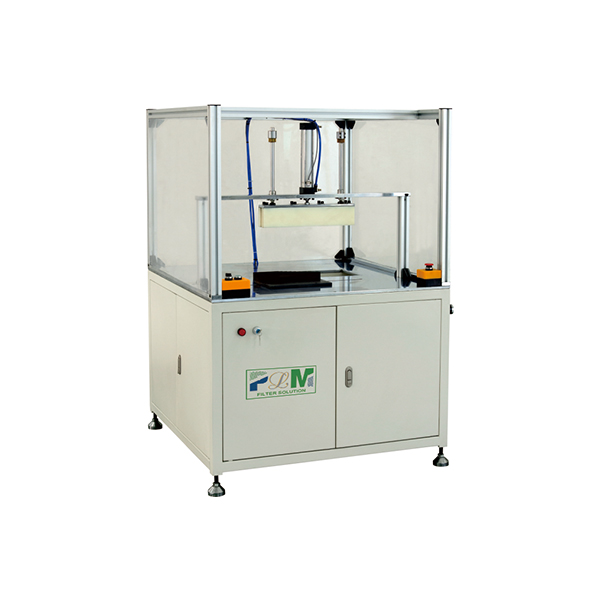

high quality plgt-600n full-auto rotary eco filter paper pleating production line

2. User-Friendly Interface The system features an intuitive control panel that simplifies operation. Operators can easily monitor production speeds, adjust parameters, and troubleshoot issues, making it accessible even for personnel with minimal technical training.

3. Versatility This production line can accommodate a variety of filter paper specifications, allowing manufacturers to switch between different products with relative ease. This versatility enables companies to adapt to changing market demands quickly.

4. Reduced Waste Through its efficient design and precise cutting technology, the PLGT-600N minimizes material waste, which not only cuts production costs but also supports sustainable practices.

5. Low Maintenance With fewer moving parts due to its automated nature, the PLGT-600N requires less maintenance compared to traditional production lines. This durability extends the lifespan of the equipment and reduces downtime.

Conclusion

The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line epitomizes the future of manufacturing—efficient, sustainable, and user-friendly. As industries continue to prioritize quality and environmental responsibility, investing in such advanced machinery becomes essential for staying competitive. By adopting the PLGT-600N, manufacturers not only enhance their production capabilities but also align themselves with global trends toward sustainability, paving the way for a cleaner, more efficient industrial future. Whether you are a small workshop or a large-scale manufacturer, integrating this production line could significantly elevate your operational efficiency and product quality, setting a new standard in the filter paper industry.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025