Nov . 04, 2024 19:46 Back to list

high performance PLFJ-2 air filter panel adhesive application machine for optimal sealing

High-Quality PLFJ-2 Panel Air Filter Gluing Machine Revolutionizing Air Filter Production

In today’s world, the importance of clean air cannot be overstated. With increasing urbanization and industrialization, air quality has become a pressing concern globally. To combat air pollution, efficient air filtration systems are essential, and at the heart of these systems lies the panel air filter. One of the most crucial aspects of manufacturing panel air filters is the adhesive application process, which is where the high-quality PLFJ-2 panel air filter gluing machine comes into play.

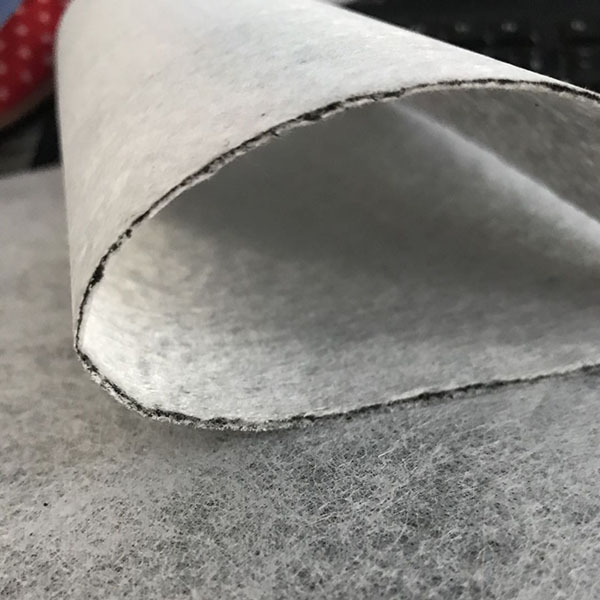

The PLFJ-2 gluing machine is designed to optimize the production of panel air filters, making it a vital piece of equipment for manufacturers focusing on quality and efficiency. Its advanced design integrates cutting-edge technology that ensures uniform adhesive application, significantly enhancing the bonding strength between the filter media and the frame. This feature is crucial as it determines the filter's overall performance and longevity.

Key Features of the PLFJ-2 Gluing Machine

1. Precision Adhesive Application One of the standout features of the PLFJ-2 is its precision adhesive application system. The machine employs advanced methods for applying glue, ensuring that a consistent bead of adhesive is dispensed across the required areas. This not only reduces the waste of adhesive materials but also guarantees a strong and reliable bond.

2. User-Friendly Interface The PLFJ-2 is equipped with an intuitive control panel that simplifies operation. Operators can easily adjust settings, monitor performance, and troubleshoot issues, leading to minimal downtime. This user-friendly design enhances productivity, allowing manufacturers to focus on output without frequent delays due to operational complexities.

3. Versatility This gluing machine is highly versatile, accommodating a range of filter sizes and types. It can seamlessly switch between different tasks, making it ideal for manufacturers that produce a variety of air filter products. This adaptability is a significant advantage in a market where customization and quick turnaround times are often required.

high quality plfj-2 panel air filter gluing machine

4. Robust Construction Built with durability in mind, the PLFJ-2 features high-quality materials that withstand rigorous production demands. Its robust design ensures that it can handle the long hours of operation typically required in a manufacturing environment. This durability translates into lower maintenance costs and longer service life.

5. Automated Process Automation is a significant trend in manufacturing, and the PLFJ-2 gluing machine is no exception. The machine reduces manual intervention through automated operations, enhancing efficiency and consistency while minimizing the risk of human error. This automation not only speeds up production but also ensures that each product meets the stringent quality standards necessary for air filtration applications.

Benefits of the PLFJ-2 Machine

The implementation of the PLFJ-2 gluing machine in an air filter manufacturing line offers several advantages. Firstly, it enhances the quality of the produced air filters, resulting in better filtration efficiency and longer service life. This, in turn, improves customer satisfaction, as end-users increasingly demand reliable air filtration systems.

Secondly, the efficiency brought about by the PLFJ-2 results in reduced production costs. By minimizing adhesive waste and enhancing the speed of production, manufacturers can lower operational costs, contributing to higher profit margins. Furthermore, the versatility of the machine allows for a more agile production process, enabling manufacturers to respond swiftly to market changes and consumer demands.

Lastly, investing in high-quality machinery like the PLFJ-2 not only increases productivity but also positions manufacturers to stay competitive in the ever-evolving air filtration market. As environmental regulations become stricter, the need for efficient and effective air filtration solutions continues to grow. The PLFJ-2 gluing machine plays a pivotal role in meeting these challenges.

In conclusion, the high-quality PLFJ-2 panel air filter gluing machine is a transformative piece of equipment that enhances the production process of air filters. With its precision application, automation, and robust design, it stands as a critical investment for manufacturers aiming to elevate their product standards and meet the growing demand for clean air solutions in a polluted world. Investing in such technology is not just a choice but a necessity for future-focused air filter production.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025