Oct . 21, 2024 21:29 Back to list

High-Performance Air Filters for Industrial Applications and Enhanced Air Quality Solutions

Industrial Air Filters Essential Components for Cleaner Air

In today's industrial landscape, maintaining air quality is more crucial than ever. As industries expand, so does the need for efficient air filtration systems. Industrial air filters play a pivotal role in safeguarding the environment, protecting human health, and ensuring compliance with regulatory standards. This article delves into the importance, types, and advancements in industrial air filters, highlighting their benefits in various sectors.

The Importance of Industrial Air Filters

Industrial air filters are designed to capture and remove contaminants from the air in manufacturing and other industrial settings. These contaminants can include dust, pollen, smoke, fumes, and even microorganisms. The primary purpose of industrial air filters is to improve indoor air quality, which is vital for the health and safety of employees. Poor air quality in an industrial environment can lead to respiratory problems, decreased productivity, and overall worker dissatisfaction.

Moreover, many industries face strict regulations regarding air quality. Compliance with these regulations is not only necessary to avoid penalties but also to promote a sustainable image and corporate responsibility. Industrial air filters help companies meet these regulatory standards while minimizing their environmental footprint.

Types of Industrial Air Filters

Industrial air filters come in various types, each designed for specific applications and levels of filtration

1. HEPA Filters High-Efficiency Particulate Air filters are known for their ability to trap 99.97% of particles that are 0.3 microns or larger. HEPA filters are commonly used in pharmaceuticals, food processing, and electronic manufacturing, where cleanliness is paramount.

2. Carbon Filters These filters are highly effective at removing odors and volatile organic compounds (VOCs). They utilize activated carbon to adsorb harmful gases, making them particularly useful in industries like printing, painting, and chemical processing.

3. Bag Filters Designed for high dust-loading applications, bag filters are used in various industries, including cement, mining, and metal processing. They can capture a wide range of particulate sizes and are essential for maintaining air quality in heavy industrial processes.

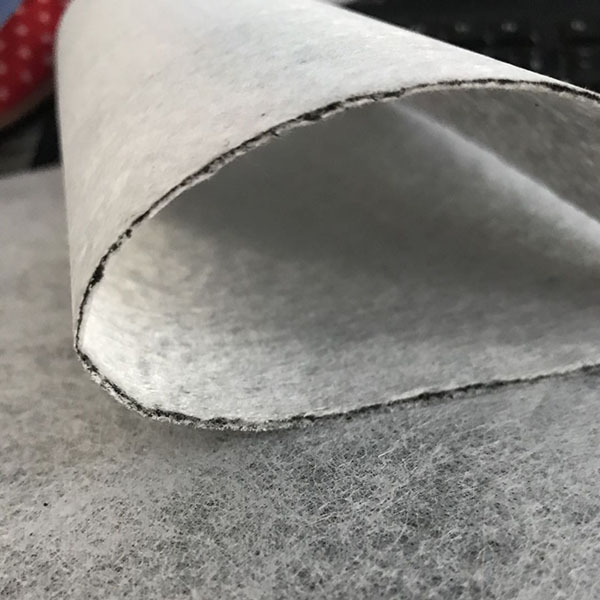

industrial air filters product

4. Pre-filters These are used as the first stage in a multi-stage filtration system, capturing larger particles and prolonging the life of downstream filters. Pre-filters are typically essential in HVAC systems and dust collection systems.

5. Electrostatic Filters These filters use an electric charge to attract and capture particles. They are commonly used in environments where air quality is critical, such as hospitals and laboratories.

Advancements in Filtration Technology

The air filtration industry is constantly evolving, driven by advancements in technology and materials. Recent developments include

- Nanofiber Technology This innovative technology enhances particle capture efficiency while maintaining low airflow resistance. Nanofibers can be used in various types of filters, improving their performance and longevity.

- Self-cleaning Filters These systems utilize advanced mechanisms to automatically clean the filter media, reducing maintenance requirements and operational costs.

- Smart Filters Integrated with IoT (Internet of Things) technology, smart filters can provide real-time monitoring and data analytics. This capability allows facilities to optimize filter replacement schedules and improve overall air quality management.

Conclusion

The vital role of industrial air filters in promoting cleaner air and safer working environments cannot be overstated. As industries continue to grow and evolve, so does the need for advanced filtration solutions. By understanding the types of filters available and the technological advancements in the field, companies can make informed decisions that enhance their operations while protecting the health of their workforce and the environment. Investing in high-quality industrial air filters not only ensures compliance with regulations but also contributes to broader sustainability goals, paving the way for a cleaner, healthier future.

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025