Nov . 28, 2024 00:56 Back to list

Fiberglass Filter Paper Suppliers for Industrial Applications and Solutions

The Growing Need for Industrial Filter Paper and Fiberglass A Supplier’s Perspective

In today's fast-paced industrial landscape, the demand for effective filtration solutions is on the rise. Industries ranging from manufacturing to pharmaceuticals require reliable filtration systems to ensure product quality and compliance with health and environmental standards. Among the various filtering materials, industrial filter paper and fiberglass have emerged as crucial components in the filtration process. This article explores the significance of industrial filter paper and fiberglass, and the essential role of suppliers in providing high-quality materials.

The Importance of Industrial Filter Paper

Industrial filter paper is a staple in numerous sectors due to its versatility and efficiency in removing impurities from liquids and gases. It is primarily crafted from cellulose fibers and is designed to capture particles, bacteria, and other contaminants, making it essential for applications such as water treatment, food processing, and chemical manufacturing. The filtration efficiency of paper can vary, allowing suppliers to provide customized solutions tailored to specific industrial needs.

One of the essential characteristics of industrial filter paper is its ability to maintain structural integrity and performance under varying conditions. This durability ensures that industries can rely on filter paper for consistent output and quality control. Additionally, filter paper can be engineered to resist different chemicals and temperatures, further expanding its applicability across multiple sectors.

The Role of Fiberglass in Filtration

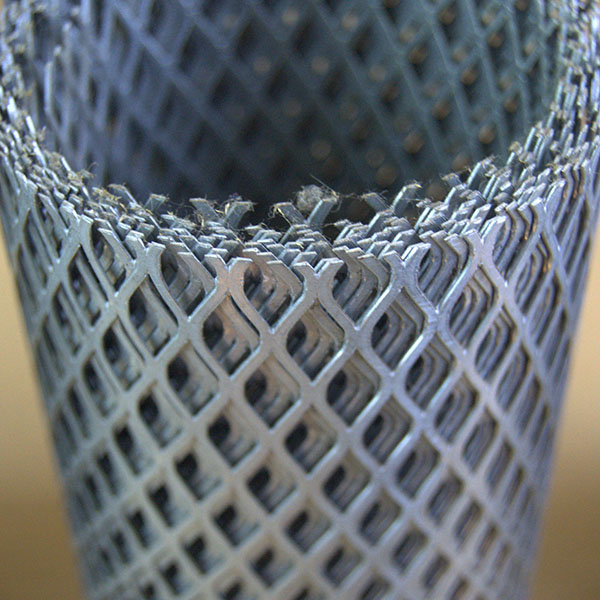

Fiberglass is another vital material in filtration applications, particularly known for its strength and thermal resistance. Fiberglass filter media are primarily used in high-temperature and demanding environments, such as gas filtration and industrial air purification. The lightweight nature of fiberglass combined with its capacity to capture fine particles makes it ideal for various applications, including HVAC systems and environmental cleanup processes.

A significant advantage of fiberglass is its high surface area, which allows for greater dirt-holding capacity and extends the lifespan of filters. This efficiency not only improves filtration performance but also translates to cost savings for industries that may face significant expenses related to filter replacement and maintenance.

industrial filter paper fiberglass supplier

The Role of Suppliers in the Filtration Landscape

As industries continue to seek innovative solutions for their filtration needs, the role of suppliers becomes increasingly vital. Suppliers of industrial filter paper and fiberglass must offer high-quality materials that meet stringent industry standards. The challenge lies in sourcing raw materials that provide optimal filtration performance while adhering to regulatory requirements.

Another critical aspect for suppliers is research and development. The filtration landscape is continuously evolving, with new technologies and materials emerging to meet the higher standards demanded by industries. Suppliers must invest in R&D to stay ahead of trends and offer cutting-edge solutions that address the unique challenges faced by their clients. This may include developing specialized filter media that combine the benefits of both paper and fiberglass or creating filters that are more environmentally sustainable.

Moreover, effective communication with clients is essential. Suppliers must work closely with manufacturers to understand their specific filtration requirements and challenges. This collaboration allows for the design of custom filter solutions that enhance operational efficiency and product quality.

Sustainability in Filtration Solutions

As industries become more environmentally conscious, sustainability has become a key focus for filter suppliers. The production of industrial filter paper and fiberglass must be aligned with sustainable practices, from sourcing raw materials to manufacturing processes. Some suppliers are now providing biodegradable filter papers or fiberglass made from recycled materials, reflecting a broader trend towards environmental responsibility.

In conclusion, industrial filter paper and fiberglass are integral to effective filtration in a variety of sectors. Suppliers play a crucial role in providing high-quality materials that meet the evolving needs of industries. As the demand for innovative and sustainable filtration solutions grows, suppliers must stay ahead of the curve through R&D, collaboration, and a commitment to quality. The future of filtration is bright, and the partnership between suppliers, manufacturers, and industries will be essential in driving advancements in this critical field.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025