Aug . 13, 2024 07:44 Back to list

Manufacturer of High-Efficiency Full-Auto Hot Melt Filter Paper Bonding Machines for Industrial Use

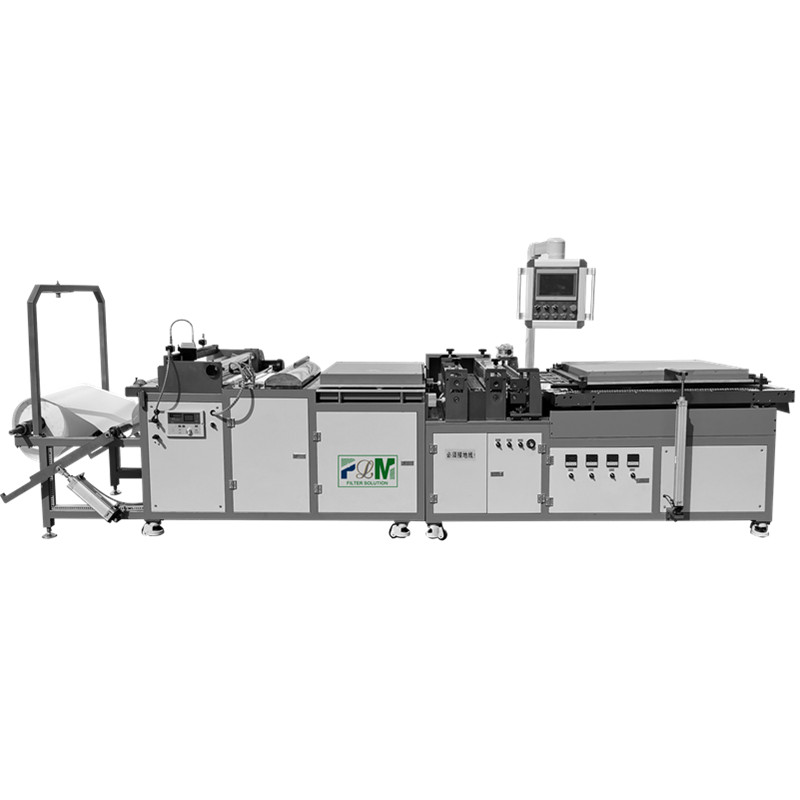

The PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine Revolutionizing Industry Standards

In today's manufacturing landscape, efficiency and precision are paramount, especially when it comes to producing high-quality products. The PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine stands out as a leading solution for manufacturers seeking to enhance their production processes. This machine not only embodies advanced technology but also addresses the diverse needs of various industries that rely on filter paper products.

Innovative Design and Functionality

The PLRZ-1000N is designed to provide a seamless bonding experience for filter papers, utilizing hot melt adhesive technology. This innovative approach ensures that the bonding is not only strong but also durable, which is essential for applications in industries like automotive, food and beverage, and pharmaceuticals. The machine automates the entire bonding process, minimizing manual intervention and thereby reducing the potential for errors. This level of automation enhances production efficiency, allowing manufacturers to meet high demand without compromising on quality.

Key Features

One of the standout features of the PLRZ-1000N is its user-friendly interface. Operators can easily navigate through various settings and configurations, enabling quick adjustments to cater to different filter paper specifications. The machine supports multiple adhesive types, providing versatility for manufacturers who may need to switch between different products or projects.

Additionally, the PLRZ-1000N is equipped with advanced temperature control systems. Maintaining optimal adhesive temperature is crucial for achieving effective bonding, and this machine ensures that the hot melt adhesive is consistently at the required temperature throughout the operation. This results in uniform bonding quality, which is essential for the performance and reliability of filter paper products.

plrz-1000n full-auto hot melt filter paper bonding machine manufacturer

Efficiency and Cost-Effectiveness

The PLRZ-1000N is designed to maximize output while minimizing waste. With its precision engineering, the machine reduces the amount of adhesive used without sacrificing bond strength. This cost-effectiveness extends to reduced material costs over time, making the investment in the PLRZ-1000N a smart choice for manufacturers looking to enhance their profitability.

Moreover, the machine’s speed and efficiency mean that manufacturers can produce more products in a shorter period, effectively increasing their overall output. This high-speed operation is particularly beneficial in industries where time-to-market is critical, allowing businesses to respond to consumer demands swiftly and effectively.

Applications Across Industries

The versatility of the PLRZ-1000N makes it suitable for a wide range of applications. In the automotive industry, for example, it is used to produce filter papers for air and oil filtration systems. In the food and beverage sector, the machine is essential for creating filters that ensure the purity and quality of products. Similarly, the pharmaceutical industry relies on precise filter papers for various applications, underscoring the machine's significance across multiple sectors.

Conclusion

As industries continue to evolve, the importance of technological advancements in manufacturing cannot be overstated. The PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine represents a leap forward in adhesive bonding technology, offering a reliable, efficient, and cost-effective solution for producing high-quality filter paper products. By investing in such state-of-the-art machinery, manufacturers can not only improve their production processes but also meet the ever-increasing demands of the market, ensuring that they remain competitive in their respective fields. The PLRZ-1000N is truly a game-changer in the world of manufacturing, setting new standards for quality and efficiency.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025