Jul . 28, 2024 01:04 Back to list

Manufacturers of Non-Woven Slitting Machines for Cabin Filters with High Efficiency and Quality

The Rising Demand for Non-Woven Cabin Filter Slitting Machines A Focus on PLHK-50%

In today's industrial landscape, the need for efficient production processes has never been more critical. This is particularly true in the automotive industry, where air quality inside vehicles is a growing concern for manufacturers and consumers alike. As a direct response to this demand, non-woven cabin filters have emerged as a popular choice due to their effectiveness in trapping airborne pollutants. To meet the increasing market demand for these filters, companies are turning to advanced machinery such as the PLHK-50% cabin filter non-woven piece slitting machine.

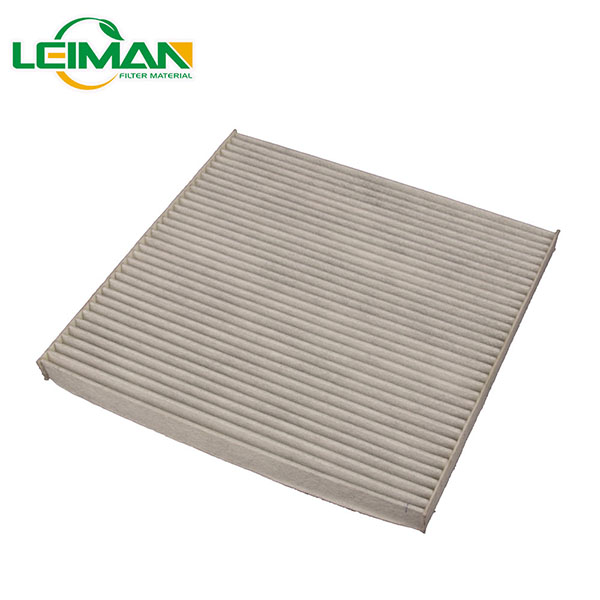

The Importance of Non-Woven Cabin Filters

Non-woven cabin filters play a crucial role in maintaining air quality within vehicles. They prevent dust, pollen, and other harmful particles from entering the passenger compartment. As consumers become more aware of the health implications of poor air quality, manufacturers are striving to produce higher-quality filtration products. This shift is driving the need for specialized machinery that can efficiently handle the materials used in non-woven filters.

Understanding the PLHK-50%

The PLHK-50% cabin filter non-woven piece slitting machine stands out in the market for its precision and efficiency. Designed specifically for the slitting of non-woven fabrics, this machine allows for the quick and accurate cutting of large rolls of material into smaller, usable sizes. The versatility of the PLHK-50% makes it suitable for various applications, from automotive filters to other industrial uses.

Manufacturers are increasingly investing in this technology not only for its performance but also for its ability to enhance productivity. The PLHK-50% is engineered with user-friendly interfaces, ensuring that operators can quickly learn to use the machine, minimizing downtime and maximizing output.

Companies Leading the Way

plhk-50 cabin filter non-woven piece slitting machine companies

Several companies are at the forefront of producing the PLHK-50% cabin filter non-woven piece slitting machine. These organizations are known for their commitment to innovation and quality, employing advanced engineering techniques to develop machinery that meets the highest industry standards. They are also focusing on sustainability, creating machines that are energy-efficient and capable of producing less waste.

Some of these companies offer comprehensive customer support, providing training and maintenance services to ensure that manufacturers can get the most out of their machines. This commitment to customer service has established them as trusted partners in the automotive and filtration industries.

The Future of Non-Woven Filter Production

As the automotive industry continues to evolve, so too will the technologies used in filter production. The demand for non-woven cabin filters is projected to rise, driven by increasing vehicle production and a growing awareness of air quality issues. Consequently, the market for slitting machines like the PLHK-50% is expected to expand, with innovations in technology paving the way for even greater efficiency and precision.

Moreover, as regulations regarding vehicle emissions tighten globally, the need for high-quality cabin filters capable of providing superior air filtration will further boost the demand for specialized machinery. Companies looking to maintain their competitive edge must invest in the latest technologies and adapt to industry changes.

Conclusion

The PLHK-50% cabin filter non-woven piece slitting machine represents a significant advancement in the production of high-quality cabin filters. With the increasing focus on air quality and pollution control, the demand for efficient manufacturing solutions will only grow. By understanding the importance of these machines and the companies behind them, manufacturers can better position themselves to meet the future challenges of the automotive industry. The journey of non-woven filter production is just beginning, and innovative machinery like the PLHK-50% will play a pivotal role in shaping its future.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025