Nov . 06, 2024 10:29 Back to list

Non-Woven Fabric Filters for Efficient Filtration Solutions and Applications

Non-Woven Filter Material A Sustainable Solution for Filtration Needs

In recent years, the demand for high-quality filtration materials has soared due to increasing environmental concerns and stringent regulations in various industries. Among the myriad of options available, non-woven filter materials have emerged as a preferred choice for many applications. These materials are not only effective in filtering but also provide numerous benefits that make them a sustainable solution for today's filtration needs.

What is Non-Woven Filter Material?

Non-woven filter materials are made from fibers that are bonded together through mechanical, thermal, or chemical processes, rather than being woven like traditional fabrics. This unique construction process allows for a diverse range of properties suitable for filtration applications. Non-woven materials can be produced in various thicknesses, pore sizes, and densities, making them versatile for different filtration standards and requirements.

Advantages of Non-Woven Filter Material

1. High Filtration Efficiency Non-woven filter materials are designed to capture particles of varying sizes, including dust, allergens, bacteria, and even viruses. Their ability to trap particles effectively stems from the random orientation of the fibers, creating a labyrinth-like structure that impedes the passage of contaminants.

2. Lightweight and Flexible The lightweight nature of non-woven materials makes them easy to handle and install in various settings, from residential HVAC systems to large industrial filtration units. Their flexibility allows them to be molded into different shapes and sizes, ensuring a perfect fit for any application.

3. Cost-Effective Compared to traditional woven filters, non-woven options tend to be more economical. The manufacturing process of non-woven materials can be less expensive, and their efficient filtration properties often mean that they require less frequent replacement, ultimately saving costs over time.

4. Sustainability Many non-woven filter materials are made from recycled or biodegradable fibers, contributing to sustainability efforts. In a world increasingly focused on reducing waste, the ability to produce non-woven fabrics that are eco-friendly is an attractive feature for both consumers and manufacturers alike.

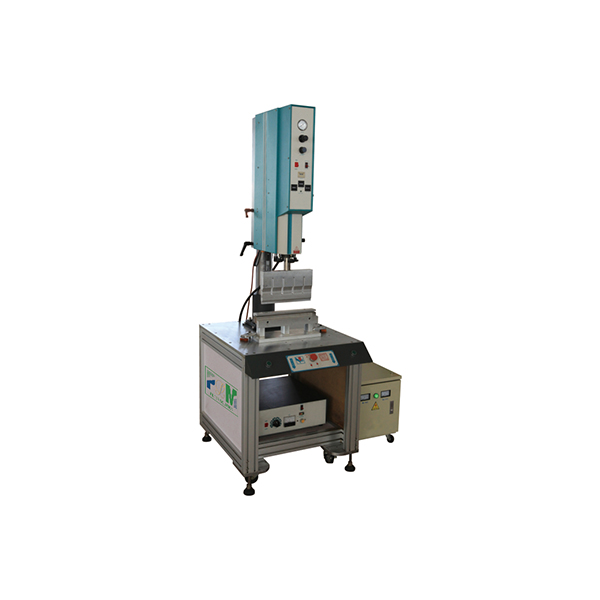

non woven filter material

5. Wide Range of Applications Non-woven filter materials are used across various industries, including air and water filtration, automotive, medical, and food processing. Their adaptability makes them suitable for applications ranging from simple air purifiers to sophisticated industrial filtration systems.

Applications of Non-Woven Filter Material

1. Air Filtration Non-woven filters are widely used in HVAC systems to improve indoor air quality. They effectively remove particulate matter and allergens, contributing to healthier living and working environments.

2. Water Filtration In water treatment facilities, non-woven materials help remove sediments and larger particles, ensuring that the water is clean and safe for consumption.

3. Automotive Filters Non-woven filter materials are increasingly being utilized in automotive applications, including cabin air filters and engine air filters. Their ability to withstand high temperatures and harsh conditions makes them ideal for the automotive industry.

4. Medical Applications In medical settings, non-woven filters play a crucial role in air and liquid filtration, protecting patients and healthcare providers from contaminants.

Conclusion

In conclusion, non-woven filter materials represent a significant advancement in the filtration industry. Their high filtration efficiency, cost-effectiveness, and sustainability make them an ideal choice for a wide range of applications. As industries continue to prioritize environmental responsibility and efficient performance, the use of non-woven filter materials is expected to grow, solidifying their role as a leading solution for filtration needs. By choosing non-woven filters, businesses and consumers alike contribute to a cleaner and healthier future.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025