Dec . 01, 2024 10:38 Back to list

plab-6 full-auto filter end cap gluing machine exporters

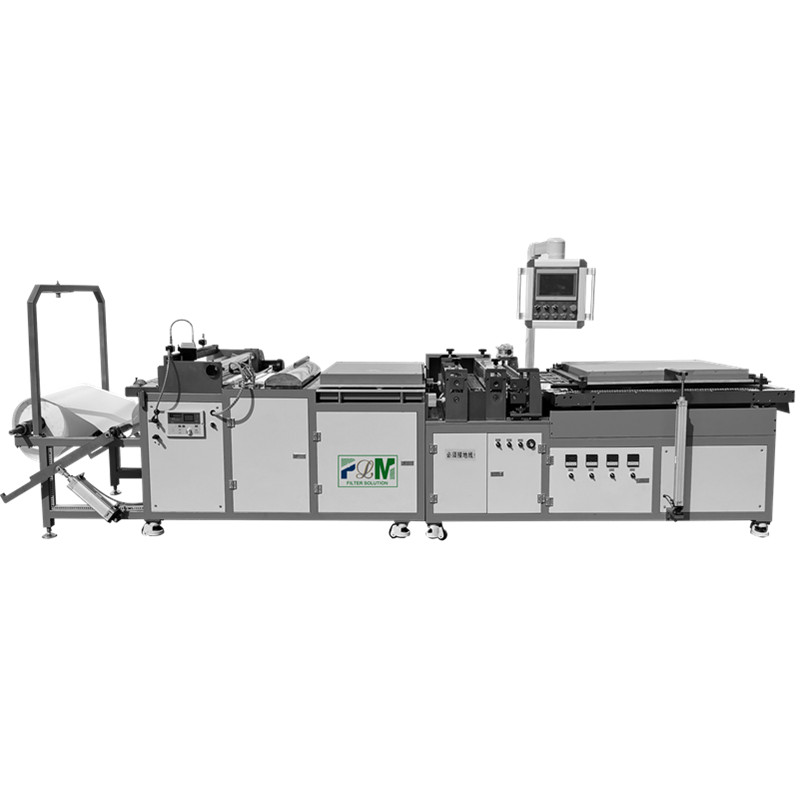

The PLAB-6 Full-Auto Filter End Cap Gluing Machine A Game Changer for Manufacturers

In the ever-evolving landscape of manufacturing, efficiency, precision, and quality are paramount. One of the prominent advancements in automation technology is the PLAB-6 Full-Auto Filter End Cap Gluing Machine, which has garnered significant attention among exporters and manufacturers engaged in the filtration industry. This innovative machine is designed to streamline the production process of filter end caps, ensuring that manufacturers can enhance productivity while maintaining the highest standards of quality.

Understanding the PLAB-6 Machine

The PLAB-6 is a fully automated gluing machine specifically engineered for the application of adhesive to filter end caps. It utilizes advanced technology to ensure precise glue application, reducing wastage and improving efficiency. The machine is compatible with various types of filters, making it a versatile addition to any production line. Its user-friendly interface allows operators to easily set parameters and monitor the production process, ensuring that the machine runs smoothly and effectively.

Key Features and Benefits

1. High Efficiency The PLAB-6 operates at a remarkable speed, capable of handling large volumes of filter end caps in a short time. This efficiency is particularly beneficial for manufacturers looking to scale their production without compromising quality.

2. Precise Glue Application The machine is equipped with state-of-the-art glue dispensing technology that guarantees accurate and consistent application. This precision minimizes excess glue usage and ensures strong adhesion, resulting in higher-quality end products.

3. Automated Processes With fully automated functions, the PLAB-6 reduces the need for manual labor, which not only increases efficiency but also lowers labor costs. The automation minimizes human error, ensuring that each filter end cap is produced consistently according to specifications.

plab-6 full-auto filter end cap gluing machine exporters

4. Versatility One of the standout features of the PLAB-6 is its ability to work with a variety of filter types and sizes. Whether a manufacturer focuses on automotive, industrial, or HVAC filters, this machine can accommodate diverse production needs.

5. Robust Design Built with durability in mind, the PLAB-6 is constructed from high-quality materials that ensure longevity even in high-demand environments. This robustness not only guarantees a longer lifespan for the machine but also translates into lower maintenance costs for manufacturers.

6. Rapid Changeover In an industry where production runs can vary significantly, the PLAB-6 offers rapid changeover capabilities. Manufacturers can quickly adjust the machine settings to accommodate different filter end cap designs, minimizing downtime.

The Export Market for the PLAB-6

As manufacturers around the world increasingly seek to enhance their production capabilities, the demand for advanced machinery like the PLAB-6 is on the rise. Exporters of this machine are tapping into international markets, providing manufacturers with access to cutting-edge technology that can help them remain competitive.

Countries with booming manufacturing sectors, particularly in Asia, Europe, and North America, are likely to benefit significantly from the integration of the PLAB-6 into their production lines. Exporters play a crucial role in facilitating this transformation by offering not only the machinery itself but also comprehensive support services, including installation, training, and maintenance.

Conclusion

The PLAB-6 Full-Auto Filter End Cap Gluing Machine is truly a game changer in the filtration industry. With its impressive efficiency, precision, and versatility, it empowers manufacturers to enhance their production processes while reducing costs and maintaining high standards of quality. As global demand for advanced manufacturing solutions continues to grow, the PLAB-6 stands out as an essential investment for forward-thinking businesses looking to thrive in a competitive landscape. The role of exporters in making this technology accessible worldwide cannot be understated, as they help bridge the gap between innovation and implementation, paving the way for a more automated and efficient future in manufacturing.

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025