Oct . 18, 2024 12:03 Back to list

Exporter of PLFJ-2 panel air filter adhesive application machinery

The Importance of PLFJ-2 Panel Air Filter Gluing Machine in the Modern Manufacturing Sector

In the current landscape of manufacturing, efficiency and precision are paramount. Among the multitude of machines that contribute to the production process, the PLFJ-2 Panel Air Filter Gluing Machine stands out as an indispensable tool for manufacturers of air filters. Its specialized design caters to the unique requirements of filter production, ensuring high-quality output while streamlining operations.

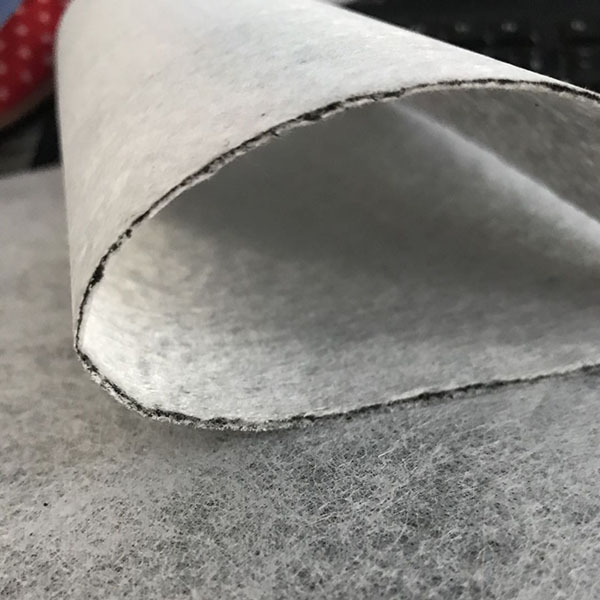

The PLFJ-2 is engineered to deliver superior glue application on panel air filters, which are essential components in various industries, including automotive, HVAC, and industrial machinery. These filters require precise assembly, as even a slight deviation can lead to inefficiencies in performance or failures in filtration. The gluing machine automates the adhesive application process, ensuring consistent and uniform coverage across all filter panels. This automation diminishes the risks associated with manual gluing, such as human error and inconsistencies in adhesive quantity.

One of the key advantages of the PLFJ-2 is its versatility. Designed to accommodate different sizes and types of filter panels, it allows manufacturers to produce a range of products in varying specifications without the need for extensive adjustments. This flexibility is particularly beneficial in a market characterized by rapid changes in consumer demand and preferences. Manufacturers can swiftly switch between product lines, meeting customer needs efficiently while maintaining production output.

Moreover, the PLFJ-2 gluing machine enhances the overall speed of the production process. With its advanced technology, the machine can perform gluing operations at a significantly faster rate than manual methods. This increased throughput not only helps to meet urgent production schedules but also aids in reducing labor costs, making operations more economically viable. For companies striving to remain competitive, the ability to produce high volumes of quality products quickly is a crucial advantage.

plfj-2 panel air filter gluing machine exporter

In addition to enhancing production speed and quality, the PLFJ-2 gluing machine is designed with energy efficiency in mind. Modern manufacturing processes are increasingly scrutinized for their environmental impact, and energy-efficient machines play a critical role in reducing the carbon footprint of production operations. By optimizing power consumption without compromising performance, the PLFJ-2 supports sustainable manufacturing practices, allowing businesses to align with eco-friendly initiatives and meet regulatory standards.

Furthermore, routine maintenance of the PLFJ-2 is streamlined through its user-friendly design. Operators can perform necessary upkeep with minimal downtime, encouraging a continuous operational flow. This reliability ensures that production schedules are met and helps to prevent costly interruptions, which can arise from equipment malfunction.

The global demand for air filters continues to rise, driven by increasing health awareness and the need for air quality control. As a result, the importance of specialized machinery like the PLFJ-2 Panel Air Filter Gluing Machine will only grow. By investing in such advanced equipment, manufacturers position themselves to meet this demand while enhancing their operational efficiency.

In conclusion, the PLFJ-2 Panel Air Filter Gluing Machine represents a significant advancement in the field of filter manufacturing. Its ability to provide consistent, high-quality gluing, coupled with its energy efficiency and versatility, makes it a valuable asset for manufacturers. As industries evolve and the market becomes more competitive, machines like the PLFJ-2 will continue to play a pivotal role in streamlining production processes and ensuring quality standards. Embracing such technology is not just an operational improvement; it's a strategic move toward long-term success in a rapidly changing manufacturing landscape.

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025