Sep . 07, 2024 11:03 Back to list

PLJL-4B Four-Station Seal Leakage Tester for Spin-On Filters

Four-Station Seal Leakage Tester for Spin-On Filters Enhancing Quality Assurance

In the competitive world of automotive and industrial manufacturing, ensuring the reliability and performance of components is paramount. One crucial aspect of quality assurance is testing for seal leakage, particularly in spin-on filters. To address this need, companies in the manufacturing sector have developed advanced testing solutions, such as the four-station seal leakage tester, specifically designed for spin-on filters.

Spin-on filters are widely used in various applications, including automotive engines and industrial machinery. They serve as essential components for filtering out impurities and maintaining the efficiency of fluids. However, the effectiveness of these filters depends significantly on the integrity of their seals. Any leakage can lead to contamination and reduced performance, making accurate testing critical to maintaining high-quality standards.

The four-station seal leakage tester is a state-of-the-art solution that enhances the testing process for these vital components. This innovative device operates in a systematic manner, allowing manufacturers to test multiple filters simultaneously, thereby increasing efficiency and reducing production time. Each station is equipped with advanced sensors to detect any leaks, ensuring that every filtered unit meets the stringent quality requirements.

pljl-4b four-station seal leakage tester for spin-on filter company

One of the key advantages of this four-station tester is its ability to provide real-time data during the testing process. This immediate feedback allows manufacturers to quickly identify any defective filters and take corrective action before they reach the market. By minimizing the risk of leaks, companies can enhance their product reliability and bolster customer trust.

Furthermore, the automation features of the four-station seal leakage tester streamline the overall testing process. With minimal human intervention required, the likelihood of human error is significantly reduced, leading to more accurate results. This efficiency not only enhances the quality of the filters produced but also optimizes the manufacturing workflow, allowing companies to focus on other critical tasks.

In conclusion, the four-station seal leakage tester represents a significant advancement in the testing of spin-on filters. By ensuring the integrity of seals and reducing the risk of leaks, this technology helps manufacturers uphold their commitment to quality and reliability. As industries continue to evolve, integrating such innovative solutions will be essential for maintaining competitive edge and meeting the ever-increasing demands of the market. Investing in advanced quality assurance methods such as seal leakage testing is not just a smart business decision; it's a necessity for sustaining success in today’s manufacturing landscape.

-

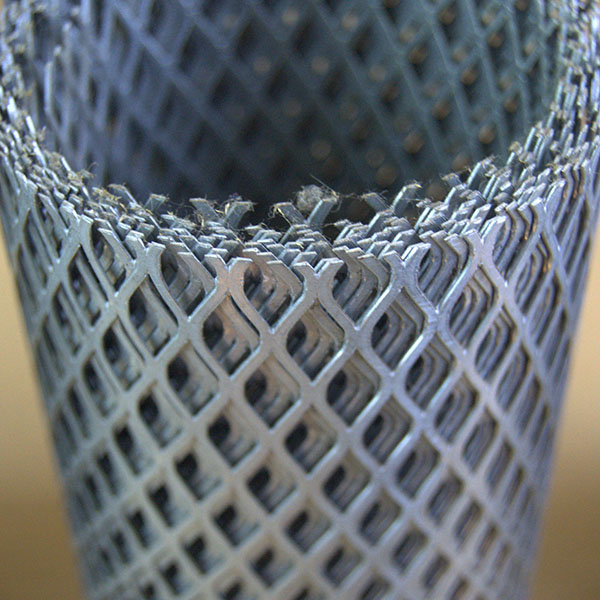

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025