Dec . 04, 2024 18:08 Back to list

pllg-2 semi-auto cabin air filter gluing machine

The Advantages of the PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine

In the automotive industry, the quality of cabin air filters plays a crucial role in ensuring a comfortable and safe driving experience. To meet the growing demand for high-quality cabin air filters, manufacturers are turning to innovative machinery. One such noteworthy piece of equipment is the PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine. This advanced machine is designed to enhance production efficiency while maintaining product quality. In this article, we will explore the advantages and features of the PLLG-2, illustrating why it is a vital investment for manufacturers.

High Efficiency

The PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine is designed for maximum efficiency. Its semi-automatic operation allows for quicker processing times compared to fully manual methods. By automating the gluing process, manufacturers can significantly reduce production times, enabling them to meet larger order volumes and tight delivery schedules. This increase in efficiency translates to cost savings and a more competitive market position.

Precision and Consistency

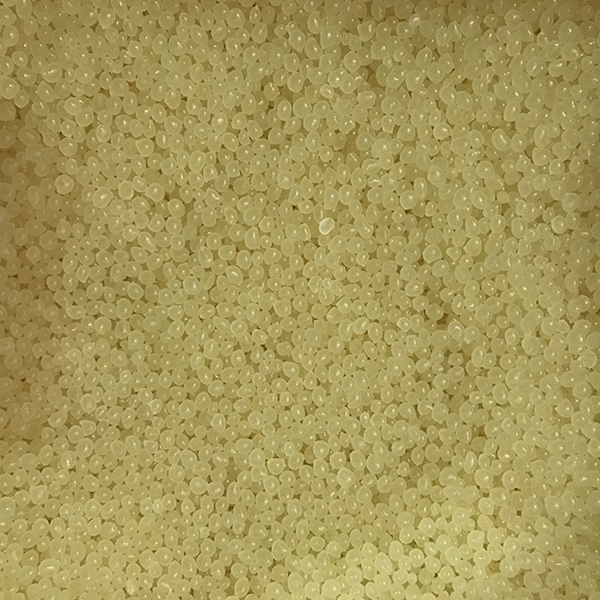

One of the key features of the PLLG-2 is its ability to deliver precise and consistent results. The machine is equipped with advanced glue application technology, ensuring that the adhesive is evenly distributed across the filter media. This precision is critical in producing cabin air filters that adhere to stringent quality standards. Consistency in production also means that manufacturers can reduce waste and enhance product reliability, ultimately leading to higher customer satisfaction.

Versatility

pllg-2 semi-auto cabin air filter gluing machine

The PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine is designed with versatility in mind. It can handle a variety of filter sizes and designs, making it suitable for different models and types of vehicles. This adaptability means that manufacturers can use the same machine for various projects without the need for significant modifications or additional equipment. As a result, the PLLG-2 is a smart investment for any manufacturer looking to expand their product range without incurring excessive costs.

User-Friendly Design

Ease of operation is another advantage of the PLLG-2. The machine features an intuitive control panel that allows operators to adjust settings quickly and easily. Moreover, the semi-automatic nature of the machine reduces the manual labor required, minimizing the risk of operator fatigue and errors. This user-friendly design not only enhances productivity but also simplifies training for new staff members.

Durability and Low Maintenance

When investing in manufacturing equipment, durability is a crucial consideration. The PLLG-2 is built with high-quality materials, ensuring it can withstand the rigors of continuous operation. Additionally, its design minimizes the need for frequent maintenance. This reliability means that manufacturers can focus on production without worrying about unexpected downtime due to equipment failures.

Conclusion

The PLLG-2 Semi-Auto Cabin Air Filter Gluing Machine represents a significant advancement in the manufacturing of cabin air filters. With its high efficiency, precision, versatility, user-friendly design, and durability, this machine offers a comprehensive solution for manufacturers looking to enhance their production capabilities. Investing in the PLLG-2 not only improves production processes but also ensures that manufacturers can meet the rising demands of the automotive market while maintaining high quality standards. Ultimately, the PLLG-2 provides a pathway to increased profitability and sustained success in the competitive landscape of cabin air filter manufacturing.

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025