Nov . 27, 2024 00:15 Back to list

Full Automatic PP Feeding Machine for Streamlined Production and Efficiency

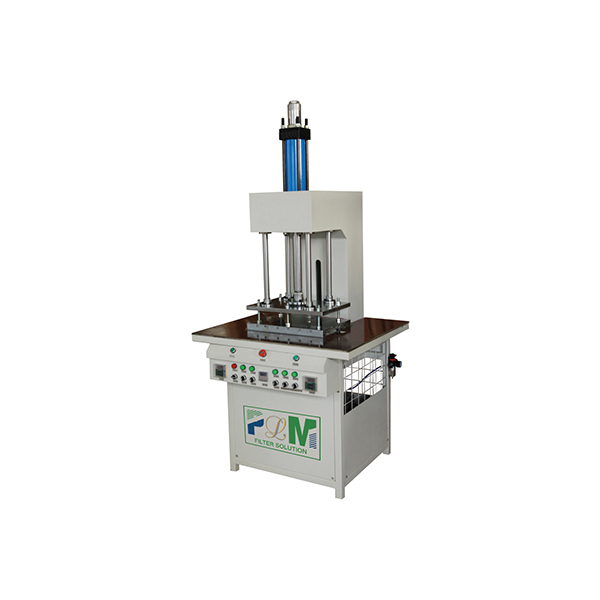

The Future of Automation PLLN-1 Full-Auto PP Feeding Machine

In the fast-paced world of manufacturing, efficiency and speed are paramount. As businesses seek to optimize their production lines, the demand for automation technologies continues to rise. One innovation that has garnered significant attention is the PLLN-1 Full-Auto PP Feeding Machine. This advanced system is designed to enhance productivity, reduce labor costs, and improve overall manufacturing efficiency.

Overview of the PLLN-1 Full-Auto PP Feeding Machine

The PLLN-1 is a state-of-the-art automatic feeding machine specifically designed for polypropylene (PP) materials. Its primary function is to streamline the feeding process in various manufacturing settings, including packaging, textiles, and plastic products. This machine boasts a robust design and cutting-edge technology, allowing it to operate efficiently in high-volume production environments.

Key Features

1. Automation Capabilities The PLLN-1 stands out due to its fully automated operation. By minimizing manual intervention, it reduces the risk of human error and ensures consistent feeding cycles. Once programmed, the machine can operate autonomously, allowing operators to focus on other critical tasks.

2. High-Speed Performance With its advanced motor and control systems, the PLLN-1 can achieve impressive feeding speeds without compromising on accuracy. This increased throughput is essential for industries that require quick turnaround times to meet market demands.

3. Versatility One of the standout features of the PLLN-1 is its ability to handle various types of PP materials. Whether it is in roll or sheet form, this machine can adapt to different sizes and specifications, making it an invaluable asset for manufacturers with diverse production lines.

plln-1 full-auto pp feeding machine quotes

4. User-Friendly Interface The machine comes equipped with an intuitive control panel that enables users to easily set parameters, monitor performance, and troubleshoot any issues. This ease of use ensures that operators can quickly become proficient in managing the machine.

5. Safety Features Safety is a critical consideration in any manufacturing environment. The PLLN-1 incorporates several safety mechanisms, including emergency stop buttons and safety guarded areas to prevent accidents during operation. These features help create a safer workplace while maintaining high productivity levels.

Economic Benefits

Investing in a PLLN-1 Full-Auto PP Feeding Machine can lead to significant economic advantages. First and foremost, the reduction in labor costs is a compelling benefit. By automating the feeding process, companies can decrease the number of workers needed for repetitive tasks, allowing them to allocate resources more effectively.

Moreover, the increased efficiency and speed of production lead to higher output, which can translate to increased revenue. Additionally, the machine’s reliability and reduced downtime contribute to lower maintenance costs over time, further enhancing its economic viability.

Conclusion A Step Towards the Future

As the manufacturing landscape continues to evolve, the need for automation tools like the PLLN-1 Full-Auto PP Feeding Machine cannot be overstated. This innovative machine not only simplifies the feeding process but also offers manufacturers a competitive edge in a crowded market. With its impressive features, economic benefits, and focus on safety, the PLLN-1 represents a significant step forward in the realm of automated production.

As businesses look to the future, investing in automation technologies will be crucial for maintaining efficiency and meeting growing consumer demands. The PLLN-1 Full-Auto PP Feeding Machine exemplifies how manufacturers can leverage technology to optimize their operations and drive productivity, thereby positioning themselves for success in an increasingly automated world.

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025