Dec . 02, 2024 05:21 Back to list

plpq-1 full-auto paper coiling machine pricelist

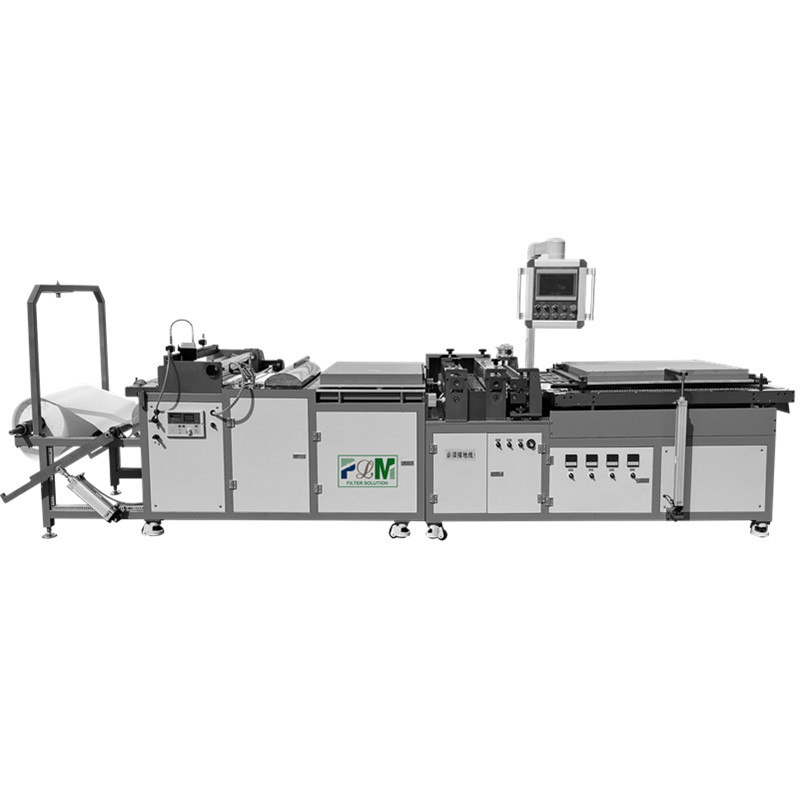

Understanding the PLPQ-1 Full-Auto Paper Coiling Machine Features and Pricing Insights

In the realm of modern packaging and printing operations, machinery plays a pivotal role in enhancing productivity and efficiency. One essential piece of equipment that has garnered attention in recent years is the PLPQ-1 Full-Auto Paper Coiling Machine. This innovative device streamlines the coiling process of paper, ensuring that companies can meet the growing demand for quick and high-quality production. Here, we delve into the features of the PLPQ-1 and provide insights into its pricing, exploring why it stands out in the market.

Key Features of the PLPQ-1

The PLPQ-1 Full-Auto Paper Coiling Machine boasts a range of features designed to optimize performance and usability

1. Automatic Operations One of the defining characteristics of the PLPQ-1 is its fully automated functionality. This allows for a significant reduction in manual labor, thereby decreasing human error and increasing production speed.

2. High Efficiency The machine is designed for high-speed operation, capable of coiling paper at impressive rates. This efficiency not only maximizes output but also minimizes production time, which is crucial for businesses facing tight deadlines.

3. User-Friendly Interface Equipped with an intuitive control panel, the PLPQ-1 makes it easy for users to operate the machine and adjust settings as needed. This feature reduces the learning curve for new operators and facilitates smooth operations.

4. Versatility The PLPQ-1 can handle various types of paper, including different weights and sizes, making it a versatile option for companies that work with a broad range of products. This adaptability is crucial for businesses looking to offer diverse services and cater to different market needs.

5. Durability and Reliability Constructed from high-quality materials, the PLPQ-1 is built to withstand the rigors of continuous operation. Its robust design ensures long-term reliability and reduced maintenance costs, making it a worthwhile investment.

plpq-1 full-auto paper coiling machine pricelist

6. Safety Features Safety is a paramount concern in any industrial setting. The PLPQ-1 is equipped with several safety mechanisms to protect operators during operation, which reduces the risk of workplace injuries.

Pricing Insights

When it comes to acquiring high-quality machinery like the PLPQ-1 Full-Auto Paper Coiling Machine, price points often vary based on several factors, including

- Manufacturer Reputation Established manufacturers may charge a premium for their machines due to their proven track record in the industry. - Custom Features Many companies offer additional customizations or features that can influence the overall cost. These may include modifications for specific types of paper or enhanced automation capabilities. - Market Demand The demand for efficient paper handling machinery can impact pricing. In times of high demand, prices may rise, reflecting the value placed on operational efficiency.

Typically, the price range for the PLPQ-1 can vary significantly. When considering a purchase, it is essential to not only assess the upfront cost but also evaluate the long-term benefits such as efficiency gains, reduced labor costs, and potential increase in production capacity.

Conclusion

In conclusion, the PLPQ-1 Full-Auto Paper Coiling Machine represents a significant advancement in paper handling technology. Its automatic features, high efficiency, user-friendly interface, and versatility make it an attractive option for businesses aiming to enhance their operational capabilities. While pricing can fluctuate based on various factors, the potential return on investment in terms of productivity and efficiency is undeniable.

For companies looking to stay competitive in a fast-evolving market, investing in advanced machinery like the PLPQ-1 can be a game-changer. As the demand for efficient and high-quality paper products continues to grow, the PLPQ-1 positions itself as a worthy contender in the machinery landscape, promising not only to meet current needs but also to adapt to future challenges in the industry.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025