Nov . 11, 2024 11:13 Back to list

plrz-250 hot melt filter element paper bonding machine companies

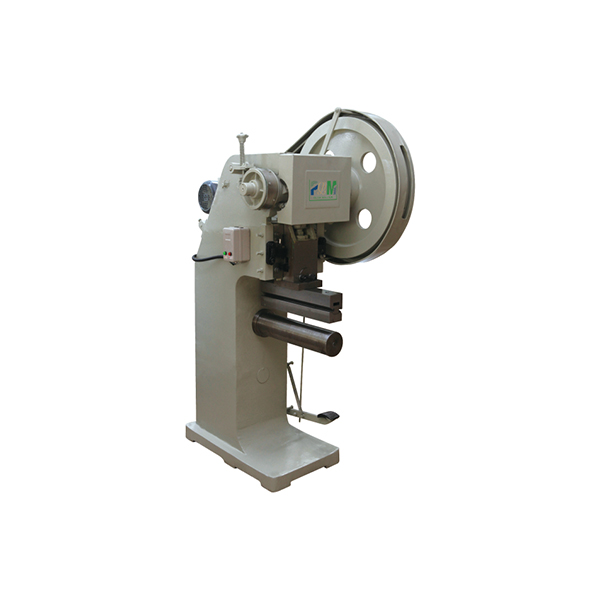

Understanding the PLRZ-250% Hot Melt Filter Element Paper Bonding Machine and Its Importance

In today's rapidly evolving manufacturing landscape, efficient and effective bonding processes play a pivotal role in various applications, particularly in the production of filter elements. The PLRZ-250% hot melt filter element paper bonding machine represents a significant advancement in this field, offering manufacturers a reliable solution for enhancing product quality, reducing production time, and minimizing operational costs.

What is the PLRZ-250% Hot Melt Bonding Machine?

The PLRZ-250% hot melt bonding machine is designed specifically for bonding filter elements using hot melt adhesives. This machine employs a combination of heat and pressure to activate the adhesive, ensuring a strong and durable bond between the filter paper and the supporting materials. The machine’s design incorporates advanced technology, allowing it to cater to various sizes and types of filter elements, making it highly versatile for manufacturers in the filtration industry.

Key Features of the PLRZ-250%

1. High Efficiency One of the most attractive features of the PLRZ-250% is its ability to produce a high volume of bonded filter elements in a short time frame. The machine's automated process significantly reduces the labor required while maintaining consistent quality across production batches.

2. Precision Control The PLRZ-250% is equipped with state-of-the-art control systems that allow for precise adjustments to temperature, pressure, and bonding time. This level of control ensures that manufacturers can achieve the desired adhesive performance, leading to superior product reliability.

plrz-250 hot melt filter element paper bonding machine companies

3. User-Friendly Interface The machine features an intuitive interface that simplifies operations, enabling even less experienced workers to operate the machine efficiently. Training time is reduced, and the risk of operational errors is minimized.

4. Eco-Friendly Operations The hot melt adhesive used in the bonding process is much safer for the environment compared to traditional solvent-based adhesives. This aligns with the growing focus on sustainability within the manufacturing sector, encouraging manufacturers to adopt greener practices.

5. Durability and Low Maintenance Built with high-quality materials, the PLRZ-250% is designed for longevity. Its low maintenance requirements not only reduce downtime but also decrease overall operational costs, making it an economically viable option for manufacturers.

Importance of the PLRZ-250% in the Filtration Industry

The ability to produce high-quality filter elements is crucial in various applications, from automotive to industrial and residential filtration systems. The PLRZ-250% hot melt bonding machine enhances the overall production process, ensuring that manufacturers can meet the stringent quality standards required in these industries. As regulations regarding air and water quality become increasingly stringent, the demand for effective filtration solutions continues to grow. The PLRZ-250% meets this demand by providing a reliable and efficient bonding method that leads to better-performing filters.

Conclusion

In conclusion, the PLRZ-250% hot melt filter element paper bonding machine is a game-changer for manufacturers in the filtration industry. Its efficiency, precision, and environmental friendliness make it an essential addition to any production line. As the demand for high-quality filtration solutions increases, investing in advanced technologies like the PLRZ-250% will provide manufacturers with a competitive edge. By optimizing production processes and improving product quality, this machine not only enhances operational efficiency but also contributes to a more sustainable future in manufacturing. Companies aiming to stay ahead in the competitive market should consider integrating the PLRZ-250% into their operations, ensuring they are well-equipped to meet the challenges of modern filtration needs.

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025