Filtration systems are essential components of everyday life whether you are at home, driving to work or in an industrial setting. Homes and offices need air filtration systems to keep the air free from dust and contaminants. Vehicles and heavy machinery need oil and fuel filtration systems to prevent the contamination of their engines. Industrial facilities use filtration systems to purify their waste gases and wastewater before disposal.

The efficiency of all filtration devices relies on the quality of their filtration media. Yet, the substance and contaminants you are dealing with determine the type of filtration devices and filter media roll you use. This article draws attention to different types of filtration fabric media and their benefits. Read on if you would like to find out more about these types of filter media.

How Filters Work

Filters are devices that facilitate the separation of solids from a fluid. The fluid can either be liquid or gaseous. As the fluid mixture passes through the filter, the solid components are retained while the fluid is let to pass.

The substance that is let through the filter is the filtrate while the solids retained are called contaminants or residue. Several factors come into consideration when selecting your filtration device and media. Below are some parameters that influence your choice of filter media.

- Size and type of contaminants

- The fluid flow rate through the filter

- Type and amount of fluid

- Solid retention capacity of the filter media

Types of Fabric Filter Media

Fabric filter media belong to a category of filter media known as thin barrier filters. This type of filter media is ideal for low density and domestic filtration operations. Thin barrier filter media are made of fabric, paper and screens. Other types of filter media such as sand beds, porous ceramics and coke beds are known as thick barrier filters. They are ideal for industrial filtration applications.

Filter material rolls are made from nylon, polyester, cotton, polypropylene or blended materials. Fabric filters can eliminate particles of varying sizes ranging from 150 microns to 2 microns in diameter. Below are examples of some of the most versatile fabric filter media

- Cotton Fabric Filter Media

- Monofilament Fabric Filter Media

- Nonwoven Fabric Filter Media

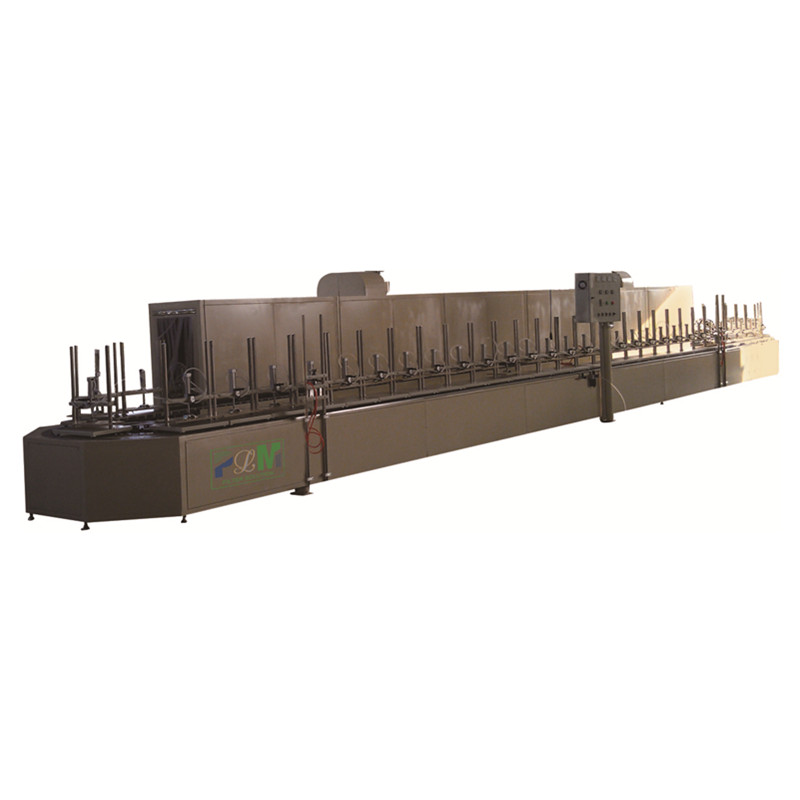

PLBL-60 Full-auto 60 stations U-type curing oven line

Cotton Fabric Filter Media

Cotton is a natural plant-based fabric that is ideal for domestic and industrial filters. Its unique characteristic is the ability to puff up and expand once installed in the filtration device. The puffed-up cotton occupies more space and increases the filter’s efficiency. Below are some additional benefits of cotton fabric as your filter media.

- Biodegradable thus creates no pollution

- Readily available

- Improved filtration efficiency

Monofilament Fabric Filter Media

Monofilament fabrics are made from single, straight heavy-set yarn. This type of fabric promotes the flow of filtrate fluid through the filtration system. They are ideal for larger sizes of contaminant. Below are some additional benefits of monofilament fabric filter media.

- Reduce the risk of clogging with its percent open area

- Easy cake release procedures

- Strong resilient fabric

Nonwoven Fabric Filter Media

Nonwoven fabrics are made from materials that are bonded together through a variety of processes. This bonding can be achieved through chemical or mechanical means. It can also involve the use of heat or solvents.

Nonwoven fabric is ideal for several filtration applications such as HEPA filtration, mineral processing, vacuum bags, coffee machinery and allergen membranes. Below are some of the popular benefits of nonwoven filter fabrics.

- Unmatched uniformity of the fabric

- High tensile strength prevents tears

- Ideal for high-temperature applications

- Lightweight

- Capacity to withstand high fluid flow rates

Fabric filter media are ideal for several both light and heavy-duty applications. They are easy to install, replace and dispose of safely. The affordability of fabric filter media reduces the operational cost of a filtration system. This makes fabric filter media the preferred choice for a wide range of filtration operations.