Oct . 18, 2024 09:36 Back to list

PP Air Filter Production Equipment Supplier and Manufacturer Solutions

The Rise of PP Air Filter Making Machine Manufacturers

In recent years, the demand for air purification has soared, driven by increasing concerns over air quality and environmental sustainability. As a result, manufacturers of air filters have seen a significant rise in the need for advanced machinery, particularly those that produce polypropylene (PP) air filters.

Polypropylene is a thermoplastic polymer known for its durability, flexibility, and chemical resistance. These properties make PP an excellent material for air filters, which are crucial in various applications, including HVAC systems, automotive interiors, industrial processes, and personal protective equipment. The growing awareness of air pollution and stringent regulatory standards have spurred the need for efficient air filtration systems, leading to a favorable market for PP air filter making machine manufacturers.

Market Trends and Innovations

The air filter industry is marked by constant innovation, with manufacturers striving to enhance the efficiency and effectiveness of their products. Recent trends have seen the introduction of advanced technologies in the fabrication of PP air filters. This includes automation in production processes, which improves efficiency and reduces labor costs. Manufacturers are investing in Research and Development (R&D) to develop machines that can produce filters with better filtration capabilities and longer lifespans.

Moreover, there is a growing trend towards the production of eco-friendly filters, as consumers and industries look for sustainable solutions. PP filters, being recyclable, fit into this narrative perfectly. Manufacturers are increasingly focusing on creating machines that can work with recycled materials, further lessening the environmental impact and appealing to environmentally conscious consumers.

Key Features of PP Air Filter Making Machines

PP air filter making machines are designed with several key features that enhance their functionality and productivity. One notable aspect is their ability to handle various types of filter media. These machines can be configured to produce different filter sizes and shapes, accommodating the diverse needs of the air filtration market.

High-speed processing capability is another critical feature, enabling manufacturers to meet the growing demand for air filters without compromising quality. The integration of digital technology allows for real-time monitoring and control of the production process, ensuring consistency and reducing waste.

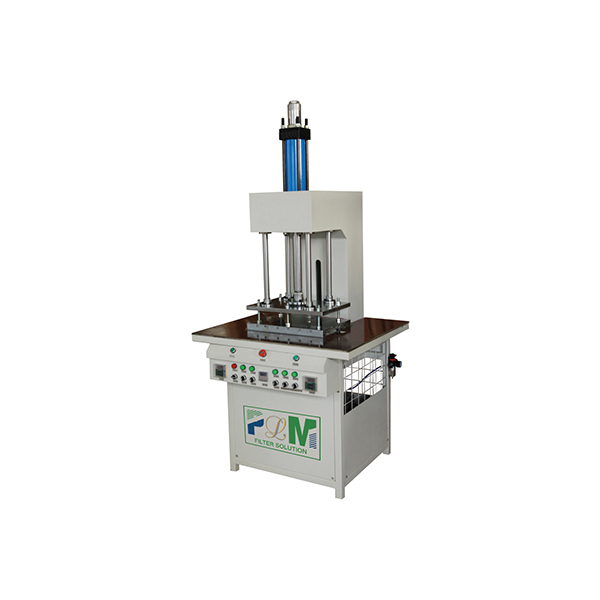

pp air filter making machine manufacturer

Furthermore, automation and robotics have played a pivotal role in streamlining operations. Automated machines not only speed up production but also minimize human error, resulting in higher-quality filters. The availability of smart manufacturing solutions, powered by the Internet of Things (IoT), is also transforming the industry, allowing for predictive maintenance and more efficient resource management.

Challenges in Manufacturing

Despite the promising landscape for PP air filter making machine manufacturers, several challenges persist. One significant hurdle is the fluctuating prices of raw materials, including polypropylene. Price volatility can impact production costs and profit margins, requiring manufacturers to develop strategies for cost management.

Additionally, as environmental regulations tighten globally, manufacturers must continuously adapt their processes to comply with new standards. This often requires substantial investments in new technologies and machinery, which can be a barrier for smaller companies. However, those who successfully navigate these challenges are likely to emerge stronger and more competitive in the marketplace.

Future Outlook

Looking ahead, the future of PP air filter making machine manufacturers appears bright. The ongoing emphasis on clean air and environmental sustainability will continue to drive demand for advanced air filtration solutions. The industry is expected to evolve with the integration of new materials, technologies, and smart manufacturing practices.

As global air quality concerns persist, and regulations become stricter, the need for efficient, high-quality air filters will only grow. PP air filter making machine manufacturers that keep pace with technological advancements and address market needs will be well-positioned for success. Ultimately, their innovations will not only contribute to cleaner air but also play a significant role in promoting a healthier, more sustainable planet.

In conclusion, the landscape for PP air filter making machine manufacturers is rapidly evolving, characterized by innovation, sustainability, and the increasing importance of air quality. As the industry continues to adapt, those who embrace change will lead the way in meeting the challenges of tomorrow’s air filtration needs.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025