Nov . 03, 2024 03:05 Back to list

pp air filter production line company

Innovative Manufacturing in the PP Air Filter Production Line A Company Overview

In the modern era of environmental concerns and air quality, the importance of air filtration systems cannot be overstated. As industries and households increasingly prioritize clean air, the demand for effective air filters is witnessing significant growth. Among the leaders in this sector is a company specializing in the production of PP (polypropylene) air filters, known for its innovative practices and commitment to quality.

The PP air filter production line is a sophisticated assembly pathway where innovation meets efficiency. The company employs state-of-the-art technology and automation to produce a range of air filters designed to meet diverse needs. These filters are essential for a variety of applications, including residential HVAC systems, industrial ventilation, and automotive air conditioning.

Manufacturing Process

The production process begins with the selection of high-quality raw materials. Polypropylene is favored due to its excellent filtration capabilities along with durability and resistance to various environmental factors. The company ensures that all materials sourced are of the highest standards, contributing to the reliability of the final product.

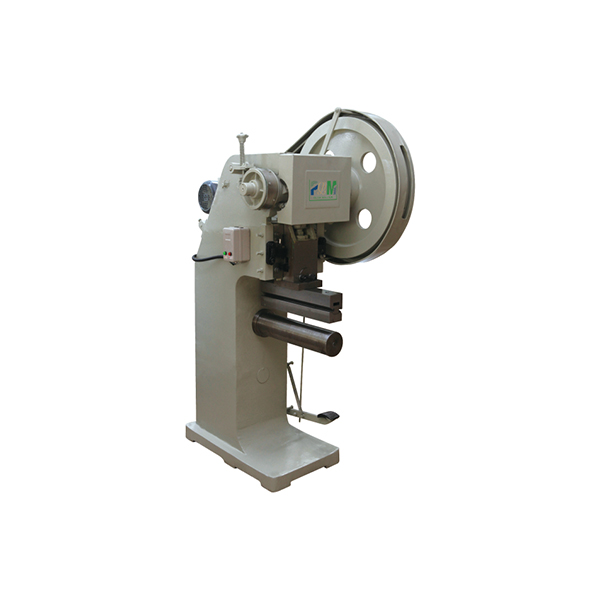

Once the materials are sourced, they undergo a series of intricate manufacturing steps. The processes involve cutting, layering, and bonding the polypropylene fibers to create a filter medium that captures particulate matter effectively. Advanced machinery is employed to maintain precision and consistency, ensuring each filter meets the specific requirements of air purity standards.

Automation plays a critical role in this production line. With the integration of robotic systems, the company has optimized operations, reducing human error and increasing production speed. This not only enhances efficiency but also allows for scalability to meet rising market demands. The result is a high-output facility capable of delivering millions of air filters annually without compromising on quality.

pp air filter production line company

Quality Assurance

One of the company’s key pillars is its commitment to quality assurance. Each filter produced undergoes rigorous testing to ensure it meets national and international standards. This includes airflow resistance, filtration efficiency, and durability assessments. The testing process guarantees that customers receive products that perform well in real-world conditions.

Moreover, the company is dedicated to continuous improvement. It regularly invests in research and development to refine its manufacturing processes and innovate new products. As air quality regulations evolve, the company is at the forefront of developing filters that not only meet but exceed market expectations.

Sustainability Initiatives

As environmental awareness grows, the company embraces sustainable manufacturing practices. The production line is designed to minimize waste and energy consumption. Efforts are made to recycle byproducts and reduce the carbon footprint of manufacturing operations. Additionally, the company is exploring biodegradable alternatives to polypropylene, aiming to lead in eco-friendly air filter solutions.

Conclusion

In summary, the PP air filter production line company is a beacon of innovation and quality within the air filtration industry. Through advanced manufacturing techniques, a commitment to quality assurance, and a focus on sustainability, the company is poised to meet the increasing demand for efficient air filtration solutions. As air quality becomes an ever more critical concern, this company's contributions will play a vital role in ensuring cleaner air for communities around the world.

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025

-

Active Carbon Air Filter for Air Purifier – Superior Filtration Efficiency

NewsJul.27,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025