Nov . 06, 2024 17:01 Back to list

Suppliers of PP Sediment Filter Production Equipment and Machinery Solutions

The Growing Market for PP Sediment Filter Making Machines

As water purification becomes increasingly critical in our modern world, the demand for efficient sediment filters has surged. Among the various types of filter technologies available, polypropylene (PP) sediment filters are gaining prominence due to their outstanding performance in removing particles and impurities from water. This rising demand establishes a consequential need for reliable manufacturers of PP sediment filter making machines.

Understanding PP Sediment Filters

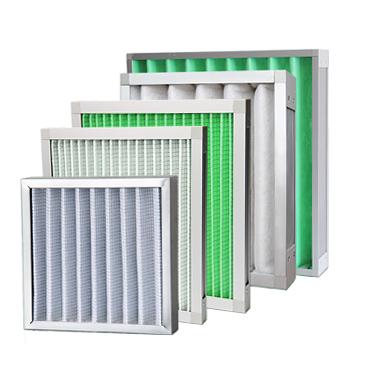

PP sediment filters are designed to trap sediments, dirt, and other particulates found in water systems. Made from high-quality polypropylene, these filters are not only durable but also resistant to a wide range of chemicals, making them ideal for both residential and industrial applications. Their lightweight nature and efficient filtration capabilities ensure they continue to be a choice for various water treatment applications, including drinking water purification, swimming pool filtration, and industrial water systems.

The Role of Making Machines

To meet the growing demand for PP sediment filters, the role of filter-making machines becomes paramount. These machines are specialized equipment designed to produce high-quality filters with precision and efficiency. Suppliers of such machines are crucial for businesses looking to enter or expand within the filtration market.

Features of Advanced Filter Making Machines

Modern PP sediment filter making machines come equipped with advanced features that enhance production capabilities. Some prominent characteristics include

1. Automation Many machines are fully automated, significantly reducing labor costs and increasing efficiency. Automation allows for high-volume production while maintaining consistent quality.

2. Customization Manufacturers often offer customization options, enabling businesses to produce filters of various sizes and specifications according to market needs.

pp sediment filter making machine suppliers

3. Energy Efficiency With a growing emphasis on sustainability, newer machines are designed to minimize energy consumption without compromising performance.

4. User-friendly Interface Many suppliers provide machines with intuitive control panels that make it easier for operators to monitor and adjust settings in real-time.

Choosing the Right Supplier

Selecting a reliable supplier for PP sediment filter making machines is critical for any business looking to thrive in the filtration industry. Potential buyers should consider several factors

- Experience and Reputation Established suppliers with a proven track record in the industry often have the reliability and expertise needed to ensure quality machines.

- Technical Support Good suppliers offer excellent after-sales service and technical support, which can be vital for troubleshooting and maintenance.

- Quality of Equipment Potential buyers should request demonstrations or detailed specifications to assess the quality and durability of the machines offered.

- Cost and Value While budget considerations are essential, it is crucial to evaluate the value offered by the machine in the context of production capability and longevity.

Conclusion

The market for PP sediment filters is expanding rapidly as the need for clean water continues to press on. In response, the demand for high-quality PP sediment filter making machines is skyrocketing. By selecting the right supplier, businesses can capitalize on this opportunity, ensuring they provide effective filtration solutions while maintaining high production standards. As the world shifts towards a more sustainable and clean future, the role of sophisticated machinery in producing reliable sediment filters will undoubtedly be significant.

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025