Sep . 11, 2025 08:00 Back to list

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

Industry Trends in Advanced Air Purification

The escalating global concerns regarding air quality, driven by industrial emissions, urban pollution, and indoor air contaminants, have propelled the demand for sophisticated air purification solutions. Industries, commercial establishments, and even discerning consumers are increasingly investing in technologies that offer superior filtration capabilities. A cornerstone of modern air purification systems, particularly for addressing gaseous pollutants and odors, is the active carbon air filter for air purifier. This technology is becoming indispensable in various sectors, from HVAC systems in smart buildings to specialized industrial processes requiring stringent air quality control.

Market analyses project a compound annual growth rate (CAGR) of over 7% for the global air purification market, with activated carbon filtration playing a pivotal role. The rising prevalence of respiratory ailments, coupled with stricter regulatory standards for indoor and outdoor air quality, underpins this growth. Innovations in material science are enhancing the adsorption capabilities of activated carbon, leading to filters with longer service lives and broader pollutant removal spectra. Furthermore, the integration of activated carbon with other filtration media, such as HEPA filters (e.g., in advanced replacement dyson carbon hepa air filter solutions), offers a multi-stage approach to capture both particulate matter and molecular contaminants, providing comprehensive air hygiene.

Technical Specifications and Structure of Active Carbon Air Filters

An active carbon air filter for air purifier primarily functions through the process of adsorption, where volatile organic compounds (VOCs), odors, and other gaseous pollutants adhere to the porous surface of activated carbon. Activated carbon itself is a highly porous material, typically derived from coconut shells, wood, or coal, that has been processed to create an intricate network of microscopic pores, significantly increasing its surface area. A single gram of activated carbon can have a surface area exceeding 1,000 square meters, providing ample sites for molecular capture.

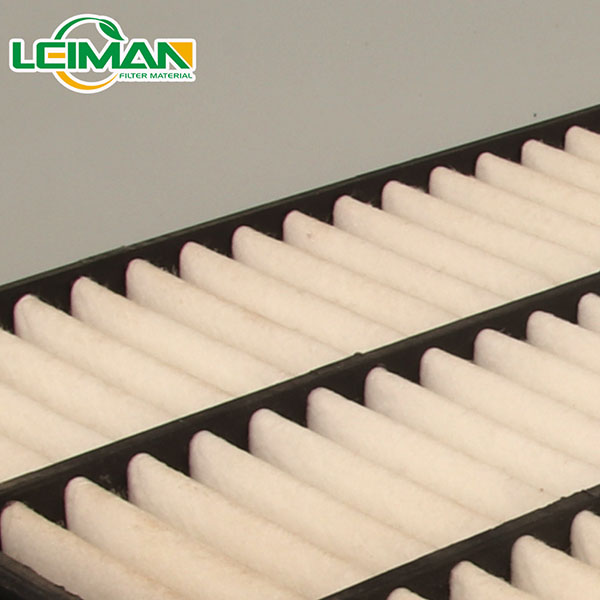

Filters are often constructed with activated carbon granules or powder embedded within a fibrous matrix, or designed as a honeycomb activated carbon filter for optimal airflow and contact time. The filter media can be integrated into various form factors, including panels, V-banks, or cylinders, to suit different air handling units. Key technical parameters include the type of activated carbon (e.g., granular, pelletized, impregnated), carbon weight, bed depth, pressure drop, and the filter's capacity for specific target pollutants (e.g., formaldehyde, sulfur dioxide, ozone). For applications requiring high-efficiency particulate removal alongside gas phase filtration, these units are often paired with particulate filters, such as those meeting merv 8 pleated ac furnace air filter standards or even HEPA equivalents, ensuring a comprehensive air purification solution.

Typical Active Carbon Filter Specifications

| Parameter | Specification Range (Industrial Grade) |

|---|---|

| Carbon Type | Coconut Shell Activated Carbon (Granular or Pelletized) |

| Iodine Number | 900 - 1100 mg/g (ASTM D4607) |

| CTC Adsorption | 50% - 80% (ASTM D3467) |

| Ash Content | Max 5% |

| Bulk Density | 0.45 - 0.55 g/cm³ |

| Operating Temperature Range | -20°C to +80°C |

| Frame Material Options | Galvanized Steel, Aluminum, Plastic (ABS/PP) |

| VOC Removal Efficiency | ≥90% (for specific VOCs, under ideal conditions) |

Manufacturing Process Flow of Active Carbon Air Filters

The production of a high-performance active carbon air filter for air purifier is a multi-stage process, meticulously controlled to ensure consistent quality and optimal adsorption capabilities. This process integrates various engineering disciplines to deliver a reliable product for critical air purification applications.

Process Steps (Schematic)

- 1. Raw Material Sourcing & Activation: High-grade carbon precursors (e.g., coconut shells, wood) are carefully selected. These materials undergo a carbonization process at high temperatures in an inert atmosphere, followed by activation (either steam or chemical) to develop their extensive pore structure. This step is critical for achieving the desired surface area and adsorption capacity.

- 2. Carbon Granulation/Pelletization: The activated carbon is then processed into uniform granules or pellets, ensuring consistent density and airflow characteristics within the filter media. For specialized applications, impregnation with chemicals (e.g., potassium iodide, phosphoric acid) can enhance removal of specific pollutants like hydrogen sulfide or ammonia.

- 3. Media Integration: Depending on the filter design, the activated carbon is integrated into a filter matrix. This could involve embedding granules into non-woven fabrics, creating pleated media, or forming honeycomb activated carbon filter structures for maximum surface exposure and minimal pressure drop. Advanced methods might include extrusion or hot-melt bonding techniques.

- 4. Frame Assembly & Sealing: The carbon media is securely housed within a robust frame, typically made from galvanized steel, aluminum, or durable plastics like ABS or polypropylene. Precision CNC machining ensures accurate dimensions for the frame components, and the media is sealed within the frame using specialized adhesives (e.g., polyurethane, hot-melt glues) to prevent air bypass and ensure structural integrity.

- 5. Quality Control & Testing: Each filter undergoes rigorous testing. This includes initial material inspection, in-process checks (e.g., carbon bed uniformity, media density), and final product performance testing. Key tests adhere to international standards like ISO 16890 (for particulate filters often paired with carbon filters), ANSI/ASHRAE 52.2, and specific internal protocols for pressure drop, airflow resistance, and pollutant adsorption efficiency.

- 6. Packaging & Dispatch: Finished filters are carefully packaged to prevent contamination and damage during transit, ready for distribution to target industries.

Target Industries: These filters are vital in various sectors, including petrochemical processing, pharmaceutical manufacturing, food and beverage production, metallurgy (for fume extraction), wastewater treatment plants (odor control), commercial HVAC systems, and data centers. Their robust construction and adherence to standards like ISO 9001 and ISO 14001 ensure reliability. The service life of an active carbon air filter for air purifier can range from 6 months to 2 years, depending on pollutant load and airflow, significantly outperforming conventional filters in terms of gaseous pollutant removal. Advantages include superior energy saving due to optimized pressure drop designs and inherent corrosion resistance of the activated carbon media and frame materials, crucial in harsh industrial environments.

Application Scenarios and Technical Advantages

The versatility of the active carbon air filter for air purifier makes it indispensable across a spectrum of demanding applications where air purity is paramount. These filters excel in scenarios requiring the removal of gaseous contaminants that particulate filters alone cannot address.

- Odor Control in Commercial & Industrial Facilities: From restaurant kitchens and wastewater treatment plants to animal husbandry facilities and industrial processing sites, activated carbon filters effectively neutralize offensive odors, improving working conditions and public perception.

- VOC Abatement in Manufacturing: Industries using solvents, paints, or chemicals, such as automotive painting lines (where a precise car auto spare parts air filter is critical for product finish) or chemical production, rely on these filters to capture VOCs, ensuring compliance with environmental regulations and protecting worker health.

- Indoor Air Quality (IAQ) in Buildings: Modern office buildings, hospitals, laboratories, and educational institutions utilize activated carbon filters within their HVAC systems to remove indoor air pollutants like formaldehyde, cleaning chemical fumes, and general indoor odors. This significantly enhances occupant comfort and health, complementing particulate filters such as f5 f6 f7 f8 f9 pocket air filter systems.

- Corrosion Protection for Electronics: In data centers and control rooms, even trace amounts of corrosive gases (e.g., sulfur dioxide, hydrogen sulfide) can damage sensitive electronic equipment. Specialized activated carbon filters, often with chemical impregnations, provide critical protection against such airborne molecular contaminants.

- Specialized Air Purifiers: High-end consumer and commercial air purifiers, including those using hepa air filter for dyson parts, integrate active carbon to deliver comprehensive air cleaning, removing pet odors, smoke, and cooking fumes alongside airborne particles.

The primary technical advantages include exceptionally high surface area for superior adsorption, broad-spectrum pollutant removal (especially for VOCs and odors), and adaptability to various system designs. Filters designed for minimal pressure drop also contribute to significant energy saving in HVAC systems, reducing operational costs while maintaining peak performance. The robust construction and material selection ensure corrosion resistance, extending service life even in challenging environments.

Vendor Comparison and Customized Solutions

Choosing the right vendor for an active carbon air filter for air purifier is critical for ensuring optimal performance and cost-effectiveness. The market offers a range of options, and discerning buyers prioritize several key factors beyond just price.

Key Vendor Comparison Metrics:

| Criterion | High-Quality Vendor | Standard Vendor (Comparative) |

|---|---|---|

| Activated Carbon Quality | High Iodine Number (>1000 mg/g), certified sourcing, uniform granulation, low ash content. Specialized impregnation options. | Variable Iodine Number, less stringent sourcing, potentially higher ash, limited impregnation. |

| Filter Construction | Robust frames (galvanized steel, aluminum), precise CNC machining, anti-corrosion treatments, bypass-proof sealing. | Lighter frames (cardboard, thin plastic), less precise assembly, potential for air bypass. |

| Performance Testing & Certifications | ISO 9001, ISO 14001, CE, specific pollutant adsorption tests (e.g., toluene, H2S) per international standards. Provides detailed test data. | Basic quality checks, less comprehensive third-party certifications, limited performance data. |

| Customization Capabilities | Tailored dimensions, specific carbon types (e.g., impregnated for mercury), frame materials, integration with pre/post filters. Full engineering support. | Limited standard sizes, few carbon options, minimal frame choices. |

| Technical Support & Warranty | Dedicated technical consulting, extended warranty, comprehensive after-sales support, lead time transparency. | Basic product support, standard warranty, less responsive after-sales. |

Customized Solutions: A reputable vendor excels in providing bespoke filtration solutions. This includes designing filters with specific dimensions to fit existing air handling units (AHUs), customizing carbon media for targeted pollutant removal (e.g., specialized rts aliexpress way compressed air filter media for oil mist and odors in pneumatic systems), or integrating various filter stages into a single module. For example, a client requiring an oil filter fit for outback legacy svx car might not need activated carbon, but the same manufacturing principles for robust housing and media integrity apply across different filtration needs. Whether it's for heavy-duty industrial applications or precise laboratory environments, the ability to tailor activated carbon loading, carbon bed depth, and frame materials (e.g., stainless steel for corrosive environments) is a significant advantage.

Application Case Studies: Real-World Impact

Our commitment to delivering high-performance filtration solutions is evidenced through successful deployments across diverse industries. These case studies highlight the tangible benefits and problem-solving capabilities of our active carbon air filter for air purifier products.

Case Study 1: Petrochemical Plant Odor Abatement

- Client: Major petrochemical processing facility in Texas.

- Challenge: Persistent mercaptan and sulfide odors from production units were impacting surrounding communities and violating local environmental regulations. Existing filtration was inadequate.

- Solution: We engineered a customized V-bank filter system utilizing impregnated activated carbon pellets, specifically tailored for sulfur compound removal. The system included multi-stage pre-filtration to protect the carbon media from particulate loading.

- Results: Odor complaints dropped by 95% within one month. Continuous monitoring demonstrated over 99% removal efficiency for target sulfur compounds. The system achieved compliance with local air quality standards, improving the client's public relations and operational stability. The robust design exhibited excellent corrosion resistance, extending the service life beyond initial projections.

Case Study 2: Pharmaceutical Cleanroom VOC Control

- Client: Large-scale pharmaceutical manufacturing plant in Europe.

- Challenge: Trace levels of solvent VOCs from adjacent processes were migrating into critical ISO Class 7 cleanrooms, posing risks to product purity and worker safety. Standard HEPA filtration was not sufficient for gaseous contaminants.

- Solution: We designed and supplied a specialized honeycomb activated carbon filter module, integrated downstream of existing HEPA filters. The honeycomb structure optimized airflow and ensured maximum contact time for VOC adsorption.

- Results: Post-installation, VOC levels in the cleanrooms consistently fell below detection limits, ensuring pharmaceutical product integrity and compliance with stringent FDA and EMA regulations. The low-pressure drop design of the filter ensured minimal impact on the cleanroom's energy-efficient HVAC system.

Case Study 3: Automotive Paint Shop Air Purification

- Client: Leading automotive manufacturer.

- Challenge: Ensuring pristine air quality in paint spray booths to prevent defects caused by airborne particles and VOCs, while also protecting workers from paint fumes. Existing particulate filtration required frequent changes.

- Solution: Implemented a multi-stage filtration system combining high-efficiency particulate filters (akin to a robust 37010 - auto car engine oil filter in terms of precision, but for air) with specialized active carbon air filter for air purifier units designed to capture a wide range of paint-related VOCs.

- Results: Significant reduction in paint defects attributed to air contaminants, leading to improved product quality and reduced rework. Worker exposure to hazardous VOCs was drastically minimized, enhancing occupational safety. The extended service life of the new filter system also resulted in notable maintenance cost savings.

Frequently Asked Questions (FAQ)

Q1: How does an active carbon air filter for air purifier differ from a HEPA filter?

A1: HEPA (High-Efficiency Particulate Air) filters are designed to capture airborne particulate matter, such as dust, pollen, mold spores, and bacteria, down to 0.3 microns with 99.97% efficiency. Active carbon filters, conversely, are designed to adsorb gaseous contaminants, VOCs, and odors through chemical bonding to the carbon's surface. They address different types of pollutants, and often, both are used in combination for comprehensive air purification.

Q2: What determines the service life of an active carbon filter?

A2: The service life depends on several factors: the concentration of gaseous pollutants in the air, the volume of air passing through the filter, the type and amount of activated carbon used, and the filter's design (e.g., bed depth). Higher pollutant loads will saturate the carbon more quickly, necessitating earlier replacement. Regular monitoring of pressure drop and air quality can help determine optimal replacement schedules.

Q3: Can these filters be regenerated or cleaned for reuse?

A3: While activated carbon itself can sometimes be thermally regenerated in specialized industrial facilities, the filter units used in HVAC and air purification systems are generally not designed for regeneration due to the complexities of cleaning the media and ensuring structural integrity. Most active carbon air filter for air purifier units are designed for single-use and are replaced once their adsorption capacity is exhausted.

Q4: Are your filters compliant with international standards?

A4: Yes, our manufacturing processes and products adhere to stringent international quality and environmental management standards, including ISO 9001:2015 and ISO 14001:2015. Performance testing often follows protocols such as ASHRAE 52.2 and relevant EN standards for air filtration, ensuring reliability and effectiveness.

Logistics, Warranty, and Customer Support

We understand that reliable supply chain management and robust after-sales support are as critical as product performance in the B2B sector. Our processes are streamlined to ensure efficiency and trust.

Lead Time & Fulfillment

Our standard lead time for common configurations of active carbon air filter for air purifier is typically 2-4 weeks, depending on order volume and specific customizations. For urgent requirements or large-scale projects, we offer expedited production and global logistics support to ensure timely delivery. Our extensive inventory of raw materials and flexible manufacturing capabilities allow us to adapt to dynamic client needs, including specialized orders like those for an rts aliexpress way compressed air filter if it requires unique carbon media.

Warranty Commitments

All our filters come with a standard 12-month limited warranty against manufacturing defects and material failure under normal operating conditions. This commitment reflects our confidence in the quality and durability of our products. Specific performance guarantees can be provided for customized solutions, tailored to the unique operating parameters and pollutant loads of your application.

Comprehensive Customer Support

Our dedicated technical support team comprises experienced engineers ready to assist with product selection, system integration, troubleshooting, and optimization. We offer:

- Pre-sales consultation and technical recommendations.

- Post-installation support and performance monitoring guidance.

- Training for maintenance teams on filter handling and replacement.

- Access to detailed technical documentation and material safety data sheets (MSDS).

Our goal is to forge long-term partnerships by delivering not just high-quality filtration products, but also unparalleled service and expertise. We serve clients globally, ensuring that whether you need an oil filter fit for outback legacy svx car (a different product entirely but an example of our diverse manufacturing capability) or highly specialized industrial air filters, you receive consistent quality and support.

Concluding Remarks

The demand for pristine air quality in industrial, commercial, and even advanced consumer settings underscores the critical role of sophisticated filtration technologies. The active carbon air filter for air purifier stands at the forefront of this evolution, offering an unparalleled solution for the removal of gaseous pollutants, VOCs, and offensive odors. Our commitment to advanced manufacturing processes, adherence to international standards, and a deep understanding of diverse application scenarios ensures that our filters not only meet but exceed performance expectations.

By focusing on high-quality activated carbon, robust construction, and continuous innovation, we deliver solutions that contribute to healthier environments, improved operational efficiency, and regulatory compliance. From safeguarding sensitive electronics to enhancing indoor air quality in occupied spaces, our filtration expertise empowers industries to achieve superior air purification outcomes. Partner with us for reliable, high-performance filtration solutions tailored to your specific challenges.

References

- International Organization for Standardization (ISO). ISO 16890:2016 - Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM).

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ANSI/ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- United States Environmental Protection Agency (EPA). Air Purifiers and Air Cleaners in Your Home. Retrieved from www.epa.gov.

- Activated Carbon for Air Purification. (2021). Journal of Environmental Science and Technology, 55(1), 123-135.

- Elsevier. Adsorption on Activated Carbon for Environmental Purification. (2018). Chemical Engineering Journal, 345, 10-25.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025