Aug . 06, 2024 05:41 Back to list

Production Equipment for High-Efficiency PU Air Filters in Manufacturing Processes

The Evolution of PU Air Filter Producing Machines

In an era where environmental concerns and air quality have taken center stage, the demand for efficient air filtration systems has surged. Among these, Polyurethane (PU) air filters are gaining prominence due to their superior performance and longevity. The production of these filters is made possible by advanced machinery specifically designed for manufacturing PU air filters. This article explores the significance of PU air filter producing machines, their components, and the technological innovations driving their development.

Understanding PU Air Filters

PU air filters are primarily utilized in various industries, including automotive, HVAC (Heating, Ventilation, and Air Conditioning), and industrial applications. These filters are characterized by their ability to trap particulate matter and allergens, providing cleaner air to both industrial settings and residential spaces. PU foam has unique properties that make it an ideal material for air filters; it is lightweight, flexible, and can be engineered to achieve the desired air permeability and filtration efficiency.

The Importance of Specialized Machinery

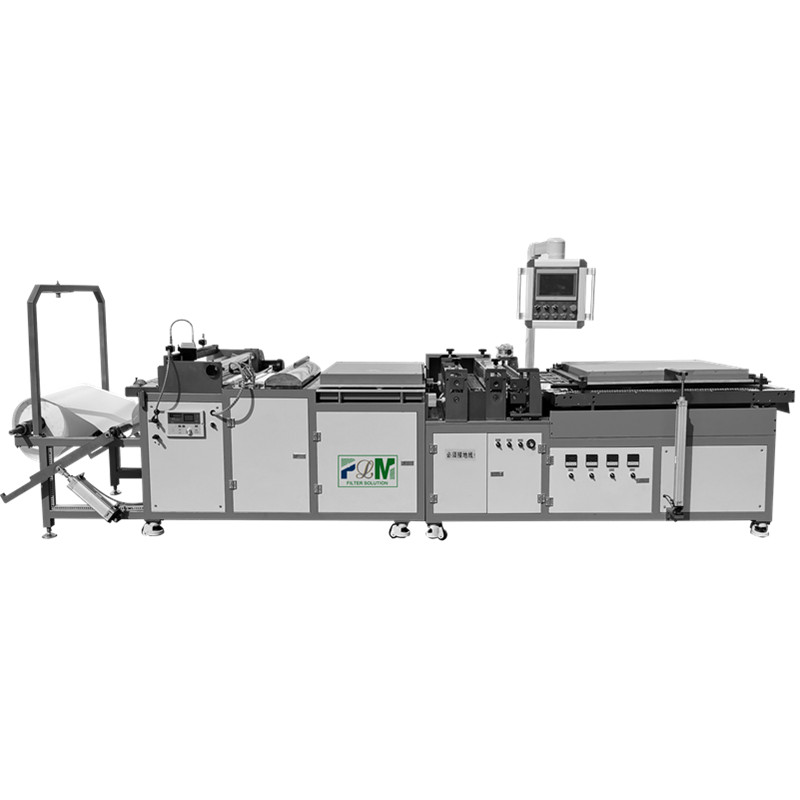

The production of PU air filters requires sophisticated machinery that can efficiently handle the unique properties of polyurethane. PU air filter producing machines are tailored to mold, cut, and assemble filters with precision. They integrate processes such as foaming, cutting, molding, and quality testing, ensuring that every filter meets industry standards.

1. Foaming Technology The first stage in filter production involves mixing polyurethane components with additives that enhance its properties. Advanced foaming machines have been developed to ensure uniform mixing and optimal curing conditions, resulting in high-quality foam.

2. Cutting and Shaping After foaming, the material must be accurately cut and shaped to fit various applications. Automated cutting machines, equipped with high-precision lasers or blades, streamline this process, minimizing waste and ensuring consistency in size and shape.

pu air filter producing machines product

3. Quality Control Quality is paramount when it comes to air filters. Modern PU air filter producing machines come with integrated testing systems that monitor the filtration efficiency and structural integrity of each filter. This reduces the risk of defects and ensures that the products meet regulatory requirements.

Innovations in PU Air Filter Producing Machines

Recent advancements in technology have led to a significant improvement in PU air filter manufacturing processes. Automation and Industry 4.0 principles have been integrated into production lines, allowing for real-time data collection and analysis. This facilitates predictive maintenance, reducing downtime and increasing operational efficiency.

Moreover, the use of environmentally friendly materials and processes is becoming a focal point. Manufacturers are increasingly exploring bio-based polyurethanes and sustainable production techniques, addressing both consumer demand and regulatory pressures related to environmental impact.

The Market Outlook

The market for PU air filters is expected to grow significantly in the coming years, driven by increasing awareness of indoor air quality and stringent regulations on air pollution. As industries prioritize sustainable practices, the evolution of PU air filter producing machines will play a crucial role in meeting this demand. Manufacturers that invest in innovative machinery will not only enhance their production capabilities but also maintain a competitive edge in the market.

Conclusion

In conclusion, PU air filter producing machines are at the forefront of the manufacturing process, ensuring that air filter products meet the growing needs for cleaner air. With continuous innovations in technology and a commitment to sustainability, these machines will evolve to produce high-quality, efficient filters for various applications, contributing significantly to improved air quality and environmental health. As industries and consumers alike prioritize air filtration, the machinery behind their production becomes increasingly vital to our health and well-being.

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025